Advantages at a glance

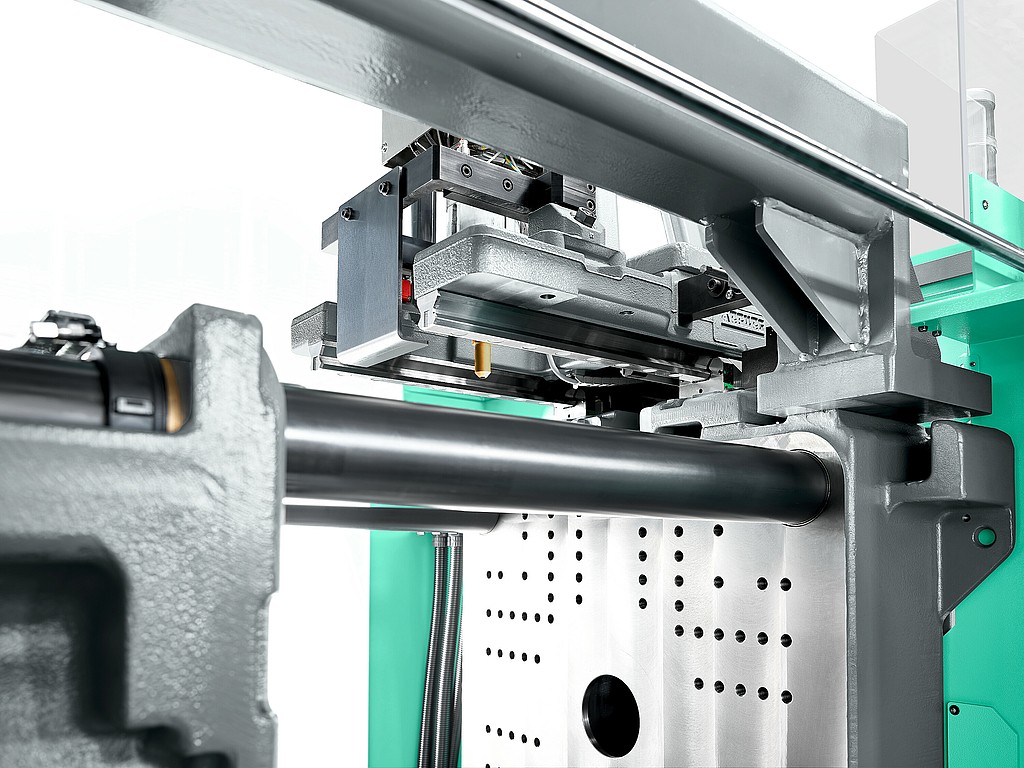

Modular

Two electric injection units. A highly dynamic electric toggle-type clamping unit with energy-efficient liquid-cooled servo motors – as standard. Selectable in various injection positions.

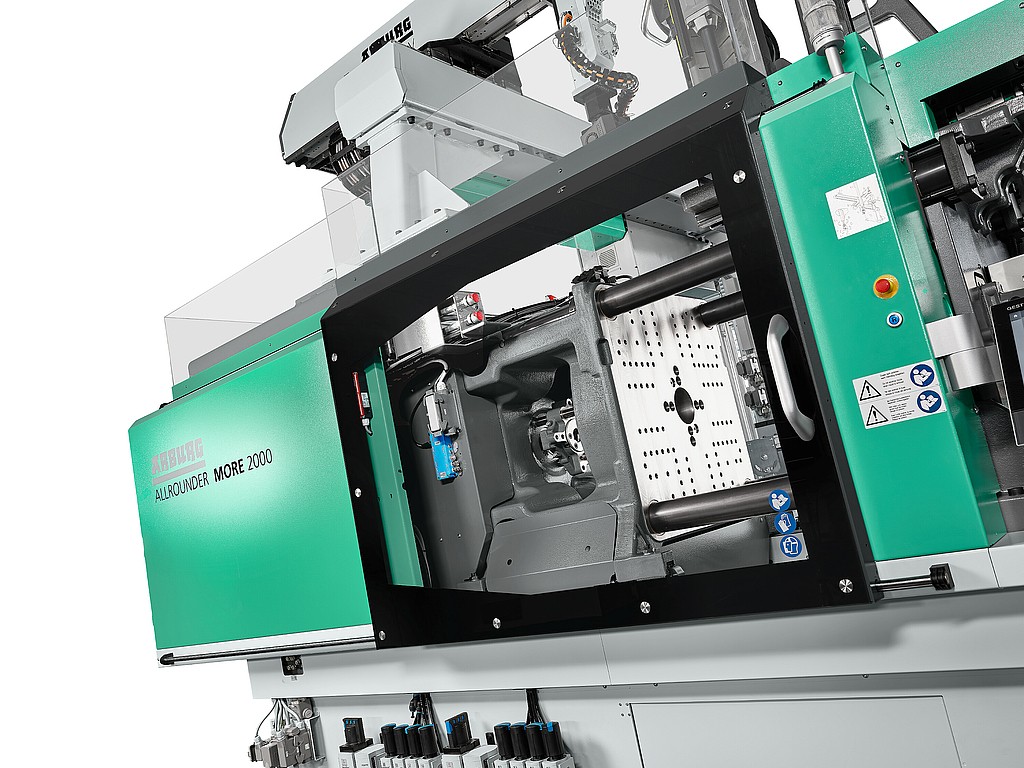

Spacious

This is what you requested: significantly more space for molds, rotary units, media connections and a usable ejector hub, accessories such as extended tie-bars and enlarged mold platens.

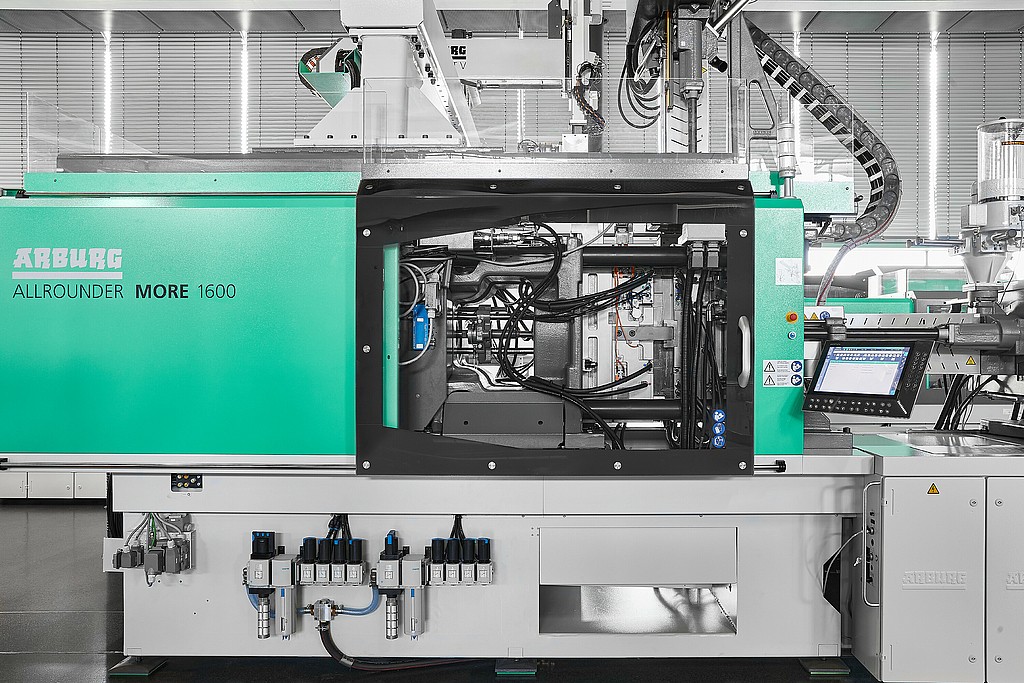

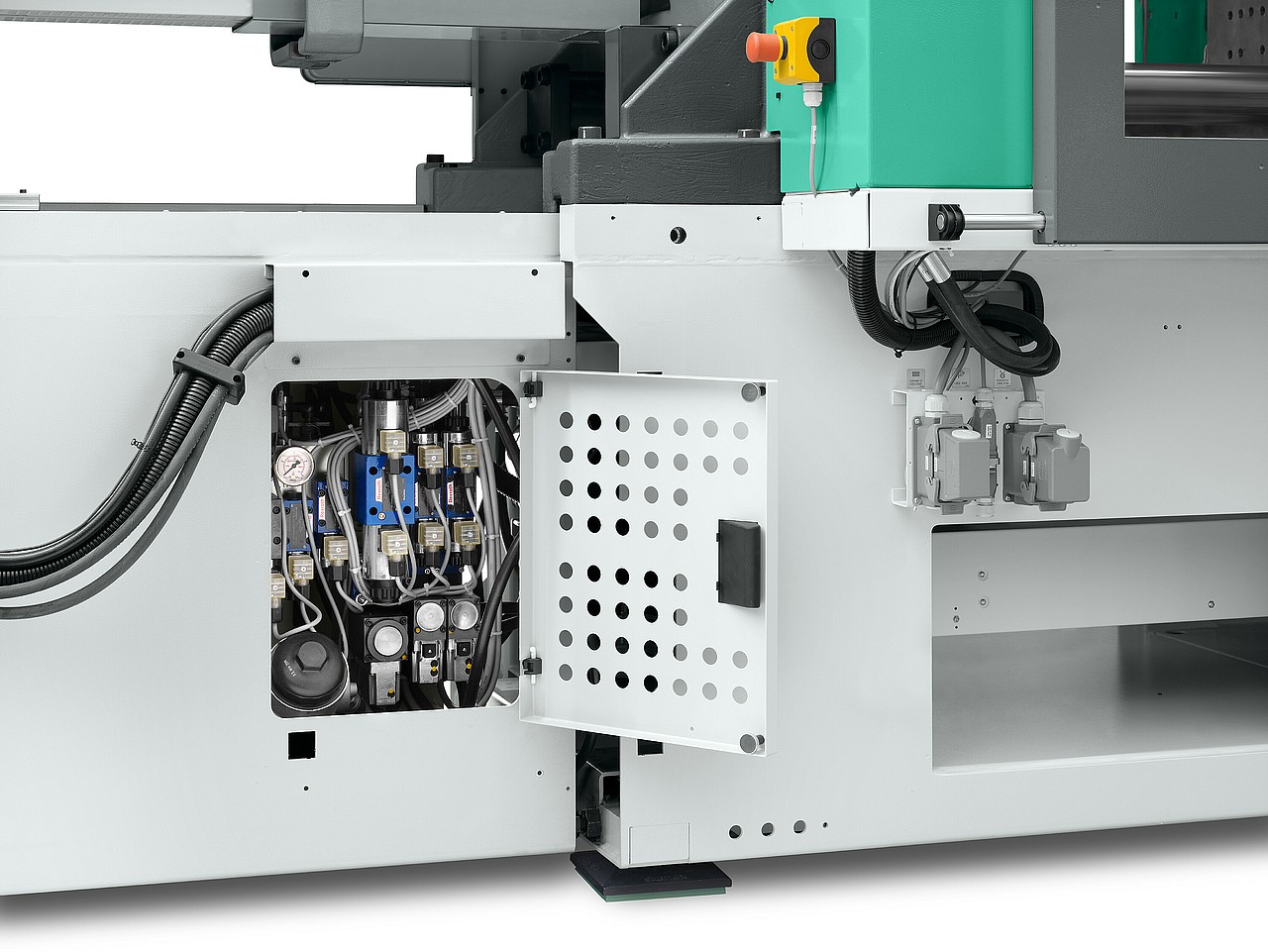

User friendly

Because you appreciate more convenience – and easy maintenance: plug-in media couplings for electrics, water and hydraulics, easy-to-change cylinder modules, material feed outside the mold area.

Flexible

Producing high-quality plastics from different colors or materials: this is where the ALLROUNDER MORE really shows its special capabilities. For your added efficiency and flexibility for a precise configuration.

Technical data

Part examples

Toothbrush

Hard/soft combinations in one casting, e.g. for toothbrushes. Also of great importance for product design. That’s what the ALLROUNDER MORE can do. Advancing as a customized multi-component machine.

Lab-on-a-Chip

Ready-to-use "lab-on-a-chip" made of transparent PC are produced in one step, using assembly injection molding and two injection molding programs. The big advantage is that there is no need for subsequent assembly or joining.

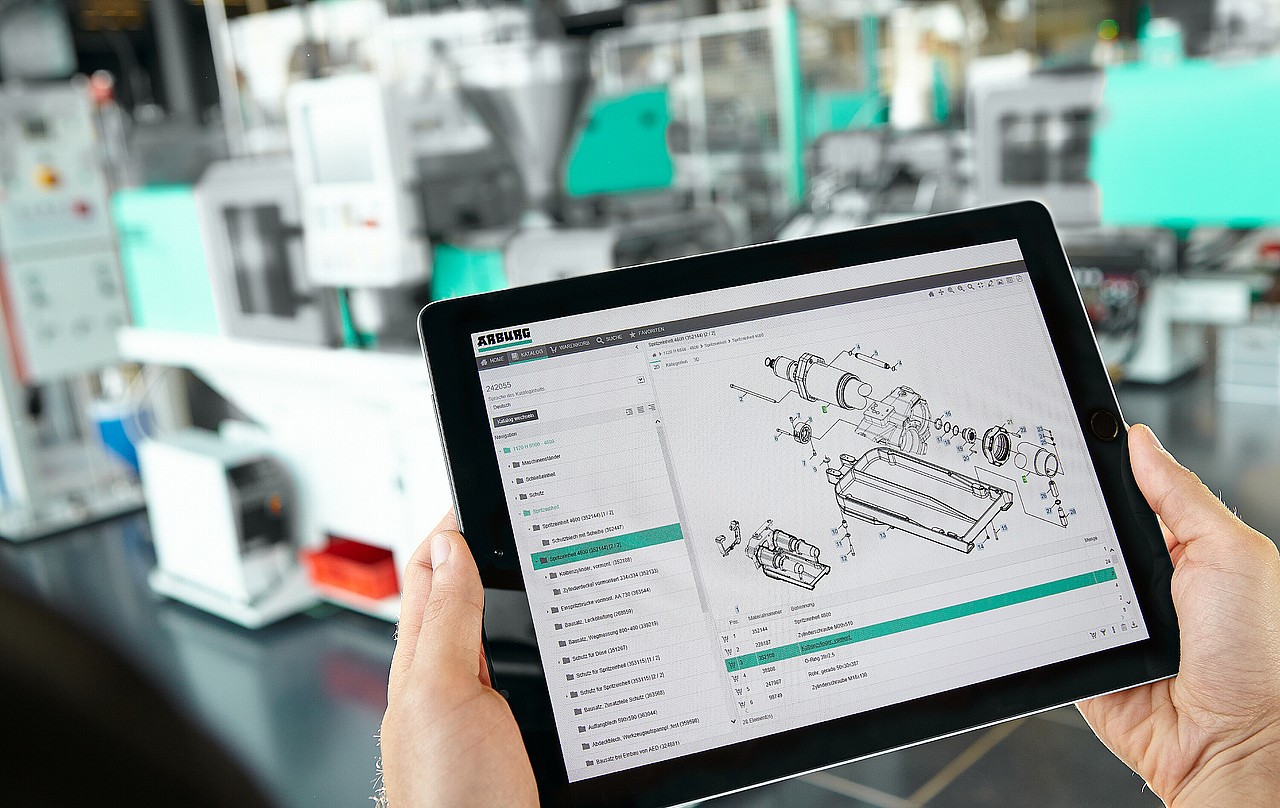

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then use our arburgXworld store for easy and interactive ordering.

This might also interest you

Electronics, medicine, mobility, packaging, complex components for a wide range of sectors. This is where you excel. So do our machines and solutions.

Producing parts with high precision and in accordance with the highest functional and quality criteria - these are the high standards that our electric ALLROUNDER ALLDRIVE machines fulfil.

What do you need for your multi-component injection molding? Very flexible configurations. As our modular ALLROUNDER. We provide solutions tailored precisely to your production requirements.