Benefits at a glance

Impressive

What's special about injection compression molding? The change in cavity volume during the injection or holding pressure phase. For the production of precise free-form surfaces, for example.

Uniform

Only when there is melt in the cavity does the mold close completely or a compression stamp move forward. This means that a uniform pressure is exerted on the corresponding surface.

Simultaneous

With injection compression molding, you can achieve larger flow path to wall thickness ratios and reduce shrinkage and warpage effects. For high dimensional accuracy and part quality.

Low-stress

What is particularly important for optical parts is that injection compression molding reduces internal stresses in the part as well as birefringence effects.

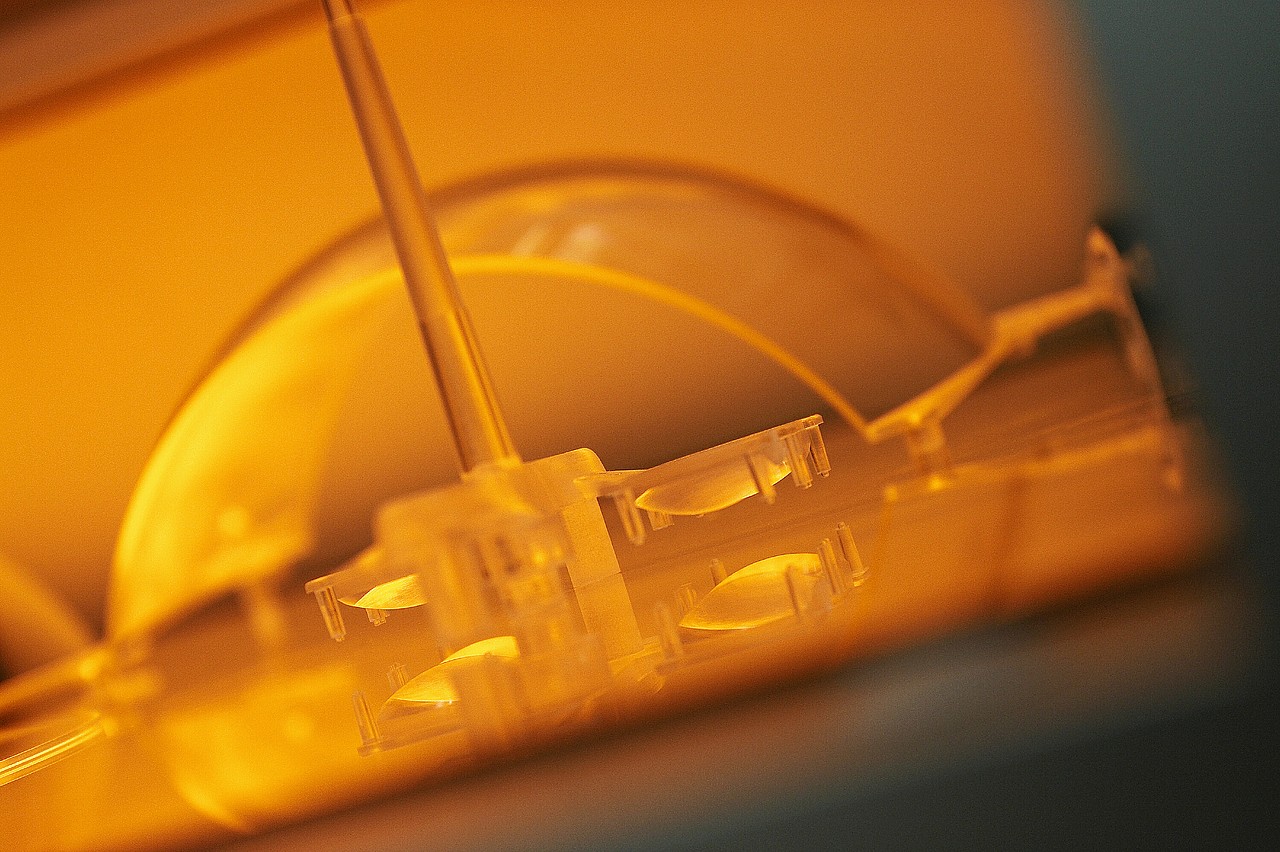

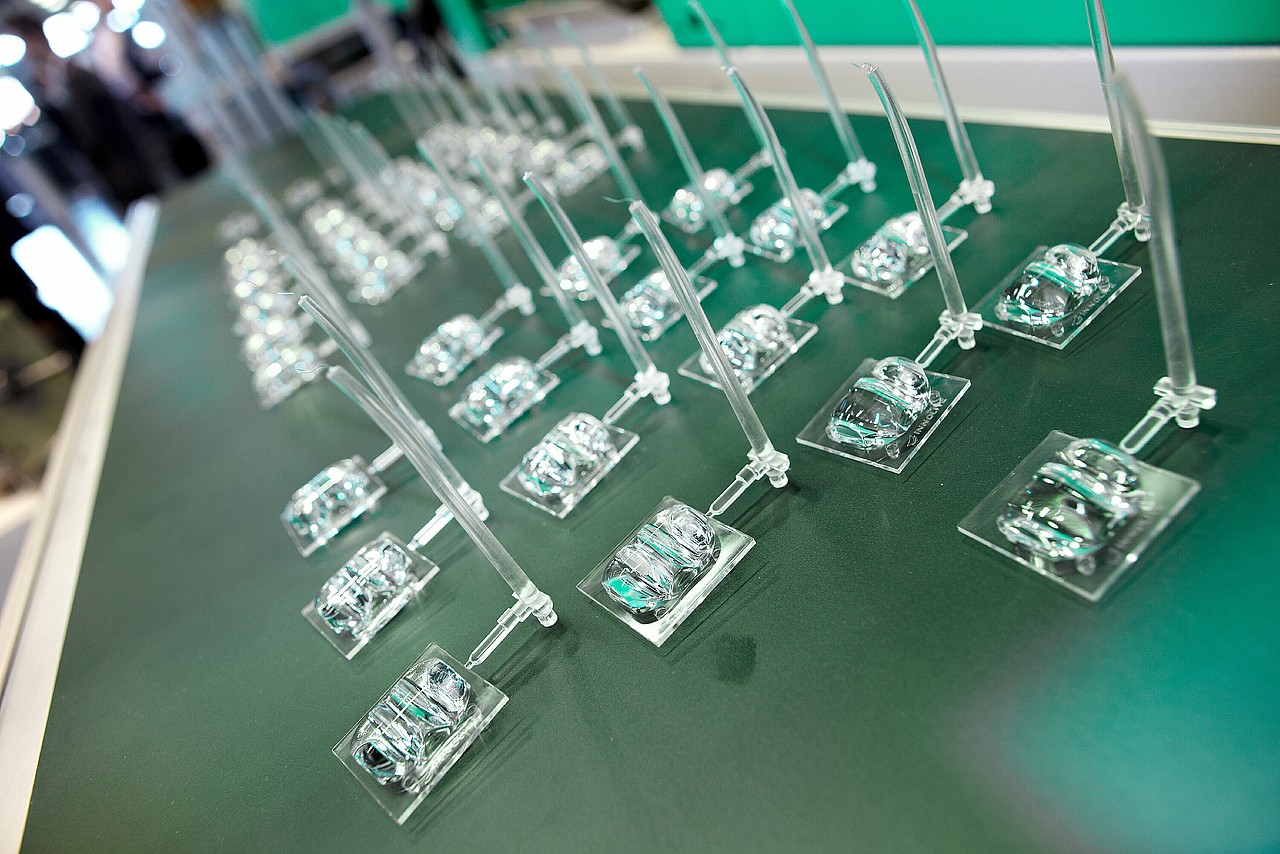

Injection compression molding: LED attachment lens example

Sample components

LED attachment lens

ARBURG is involved in the OptiLight research project: Injection-molded precise free-form surfaces purposefully direct the light of innovative hybrid optics into a rectangular illumination profile.

Belt pulley

With thermosets, injection-compression molding can be used to increase part strength and avoid sink marks. For the belt pulley, the coining gap in the mold is 7 mm.

Spectacle lens

In opthalmic lenses for spectacles, the thickness of the part can be adjusted by means of the compression path. The coining time for a 10 mm thick lens is 90 seconds.

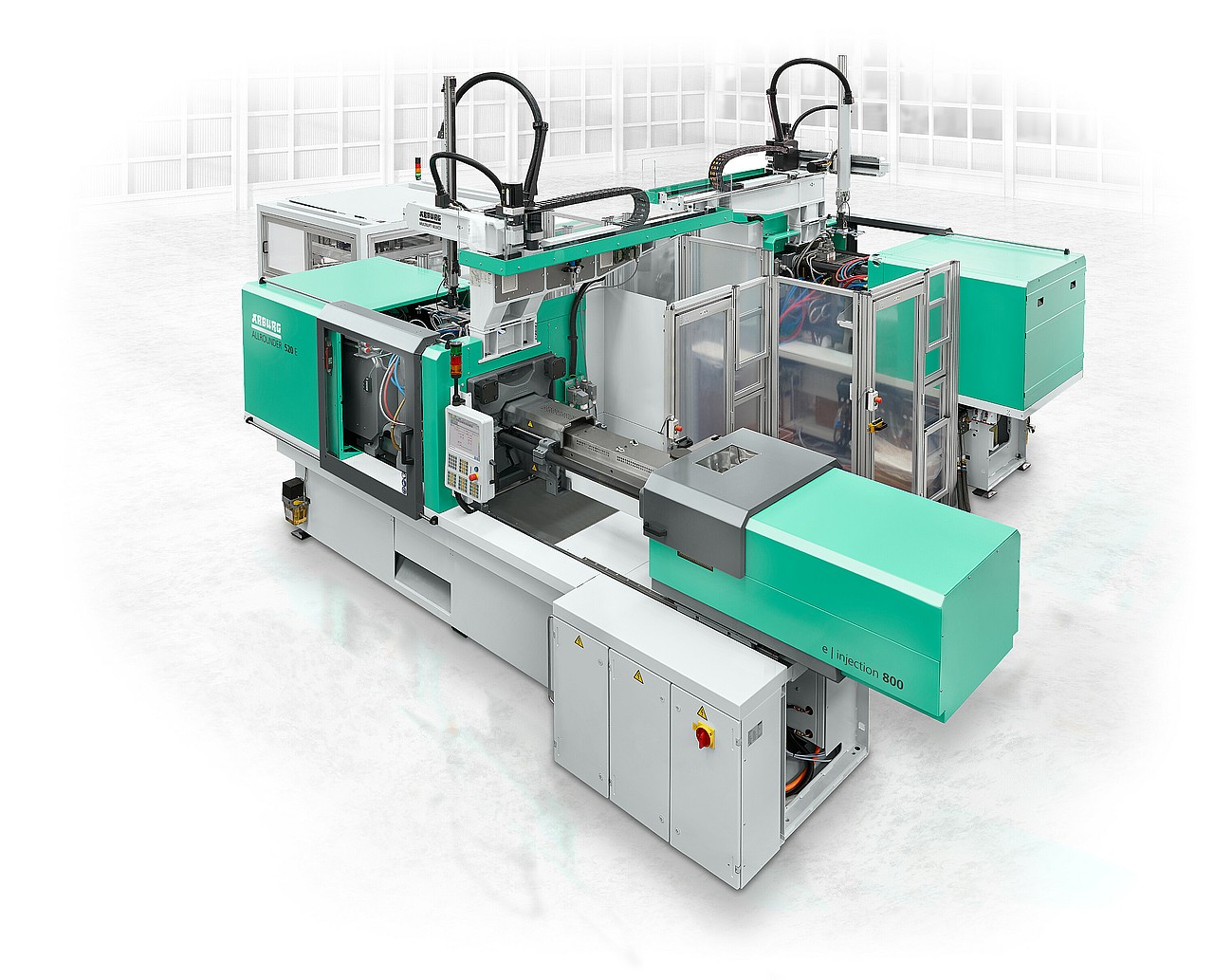

Automated production cells from a single source

Want to increase added value, optimize the injection molding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

This might also be of interest

Producing parts with high precision and in accordance with the most stringent functional and quality criteria – this is what our electric ALLROUNDER ALLDRIVE machines are designed to achieve.

Take advantage of our expertise – from molded part design to mold and machine configuration. And application technology, for example in our Customer Center.

From practical experience – for practical use. That's how we share knowledge. You benefit from our expertise. Targeted, fast, and cooperative. With our machines, for your purposes.