WIR SIND DA.

As one of the world's leading manufacturers of high-quality machines for plastics processing, we ensure day after day that you successfully produce plastic parts.

By integrating innovatiQ and AMKmotion, we have invested in the technological future and in strong teams. Injection molding, additive manufacturing, and the entire drive train come from the ARBURG family.

You can rely on our services. Every time. Everywhere in the world. What do you gain from reliable consulting, training, maintenance, and genuine spare parts? A quick return to seamless production.

ARBURG can provide you with everything you need to digitalize your company. Smart ALLROUNDERs and freeformers, our ARBURG host computer system (ALS), and the arburgXworld customer portal apps with all digital services.

Work with us to make plastics processing more sustainable. Resource-saving production, rational processing of materials, use of recyclates – together we can reduce the carbon footprint.

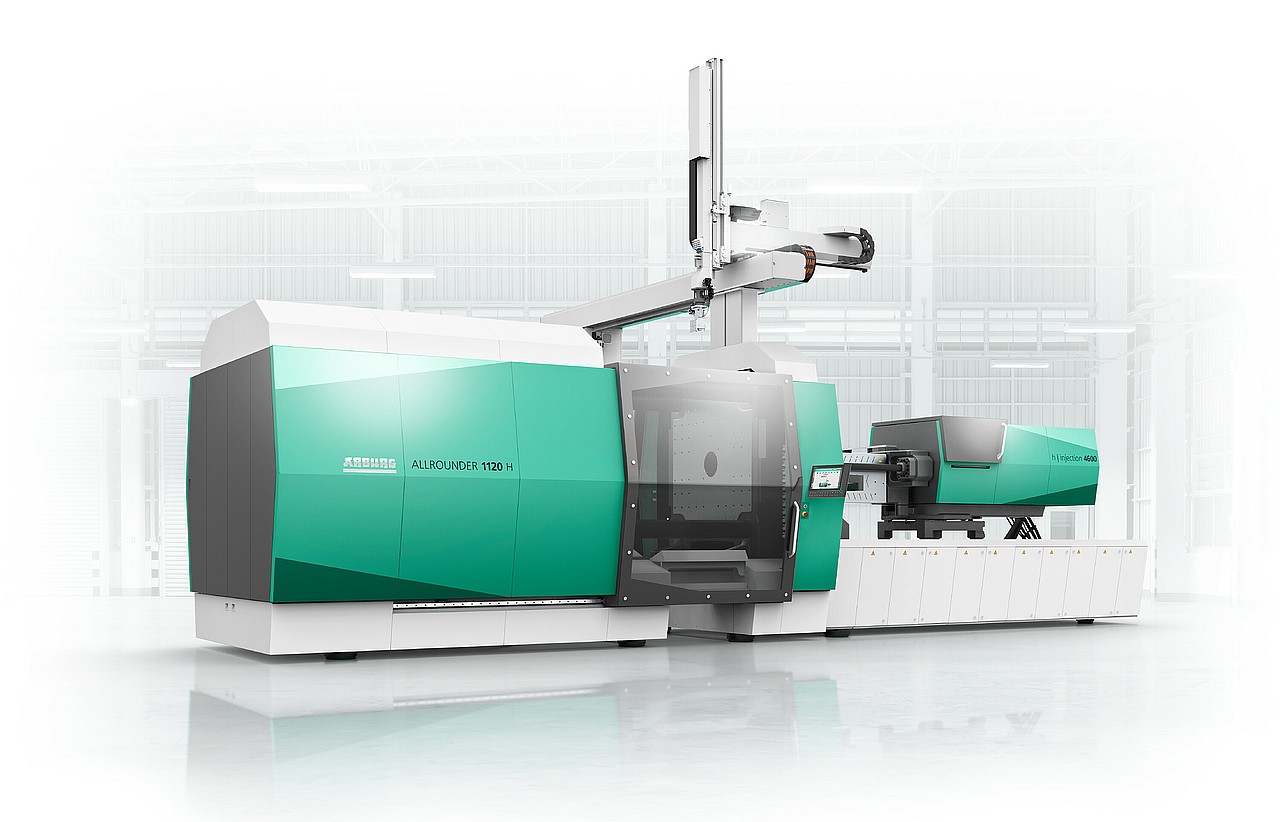

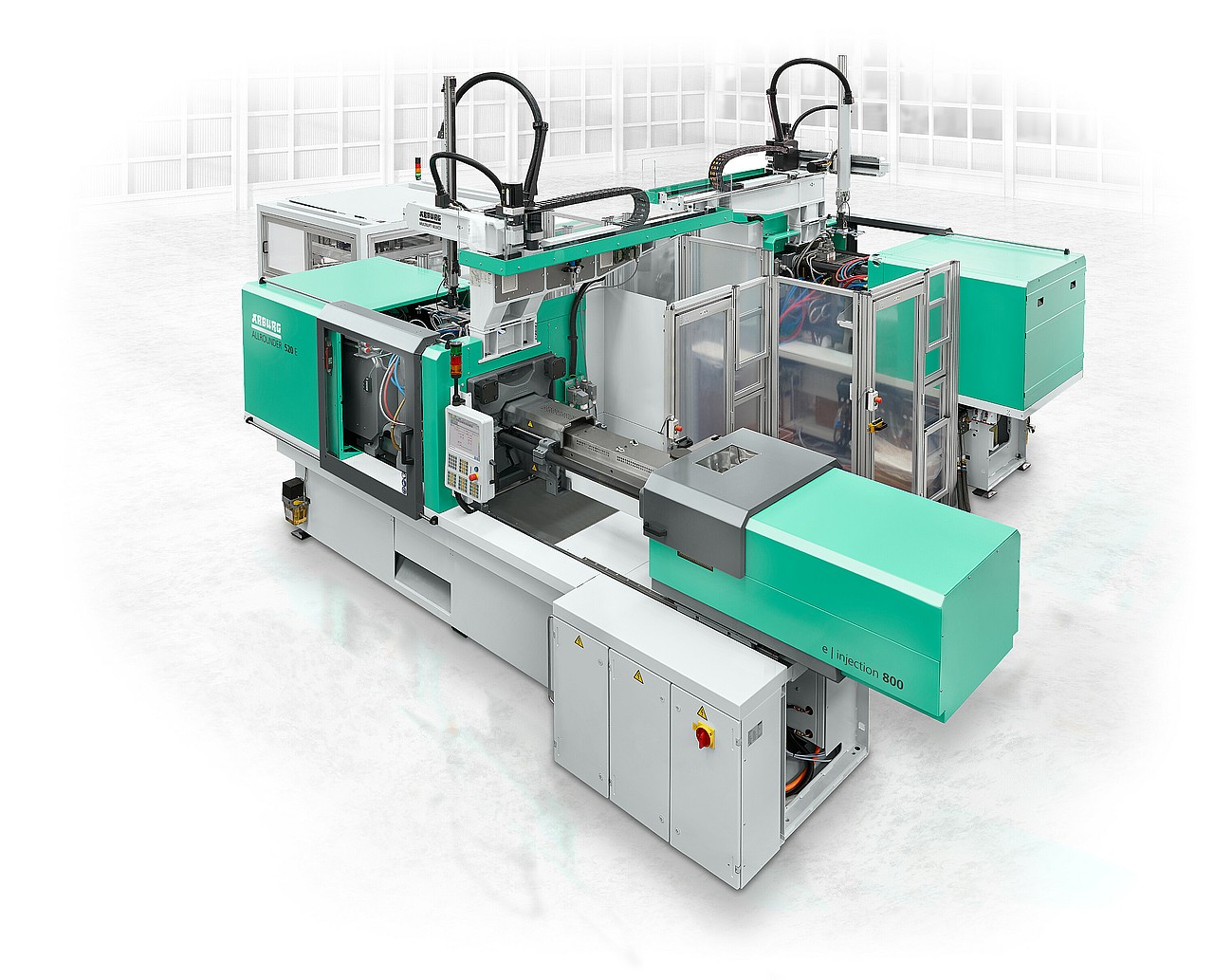

Place your trust in the best in injection molding technology. Our modular product range includes hydraulic, hybrid, and electric injection molding technology – from consistently standardized entry-level models to customized machines. From performance versions to high-speed machines. Our ALLROUNDERs make everything possible.

Customized 3D printing – the ARBURGadditive Group offers freeformers from ARBURG and 3D printers from innovatiQ. Plus the ARBURG Plastic Freeforming (APF), Fused Filament Fabrication (FFF), and Liquid Additive Manufacturing (LAM) technologies.

Automated production cells from the system supplier. ARBURG combines injection molding machines, robotic systems, and extensive peripheral equipment from respected partners to create your customized turnkey system. Our experts provide advice starting from the idea to the finished project and, working together with you, tailor the technology exactly to your needs.

Prepare to be fascinated. And inspired. By sophisticated components produced on ALLROUNDERs and freeformers from ARBURG. Efficient, sustainable, economical – no problem at all. You can select according to sector, technology or material if required.

With our comprehensive expertise, you can produce high-quality injection-molded or additively manufactured plastic parts, for example for use in packaging, medicine, automotive, mobility, leisure, and mechanical engineering. ARBURG has exactly the kind of specific system solutions you need.

At ARBURG, a wide range of processing technologies are available to you: from micro injection molding and LSR processing, through lightweight construction and clean room production, to special processes such as cube-mold technology and industrial 3D printing. Just click your way through.

Whether for injection molding or additive manufacturing: with our machines, you can process all commercially available plastic granules that you need for your components. New products alongside recyclates, bioplastics, powder materials, and compounds – always with top-quality results.