UVEX sunglasses: "ready to wear" in one step

ARBURG solutions used

ALLROUNDER 570 A

An electric ALLROUNDER 570 A with OPC UA interface produces ready-to-use UVEX sunglasses of consistently high quality in a cycle time of 50 s. The "aXw Control FillAssist" was used to set up the demanding application.

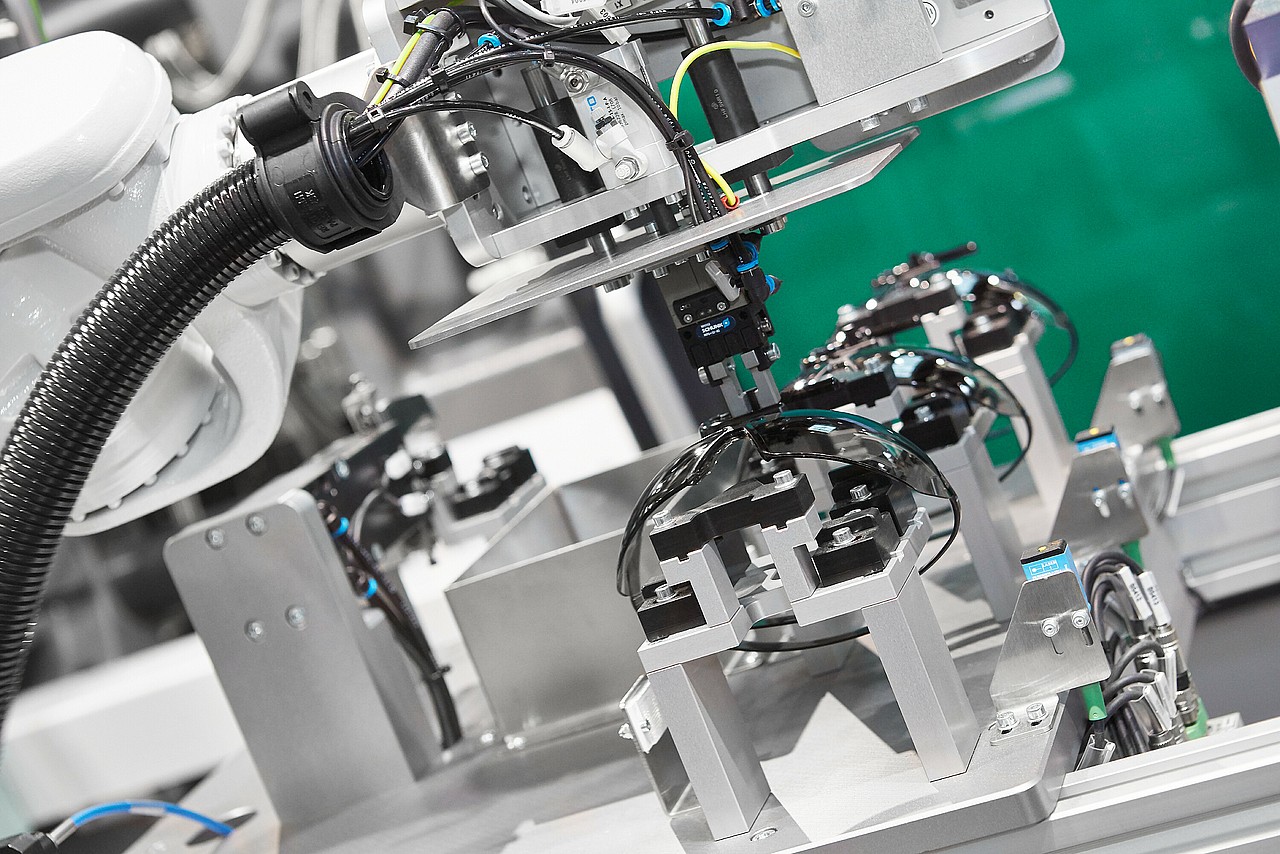

Six-axis robot

A six-axis robot handles the careful removal and reliable handling of the sunglasses for the downstream steps of laser marking, quality inspection and sprue separation.

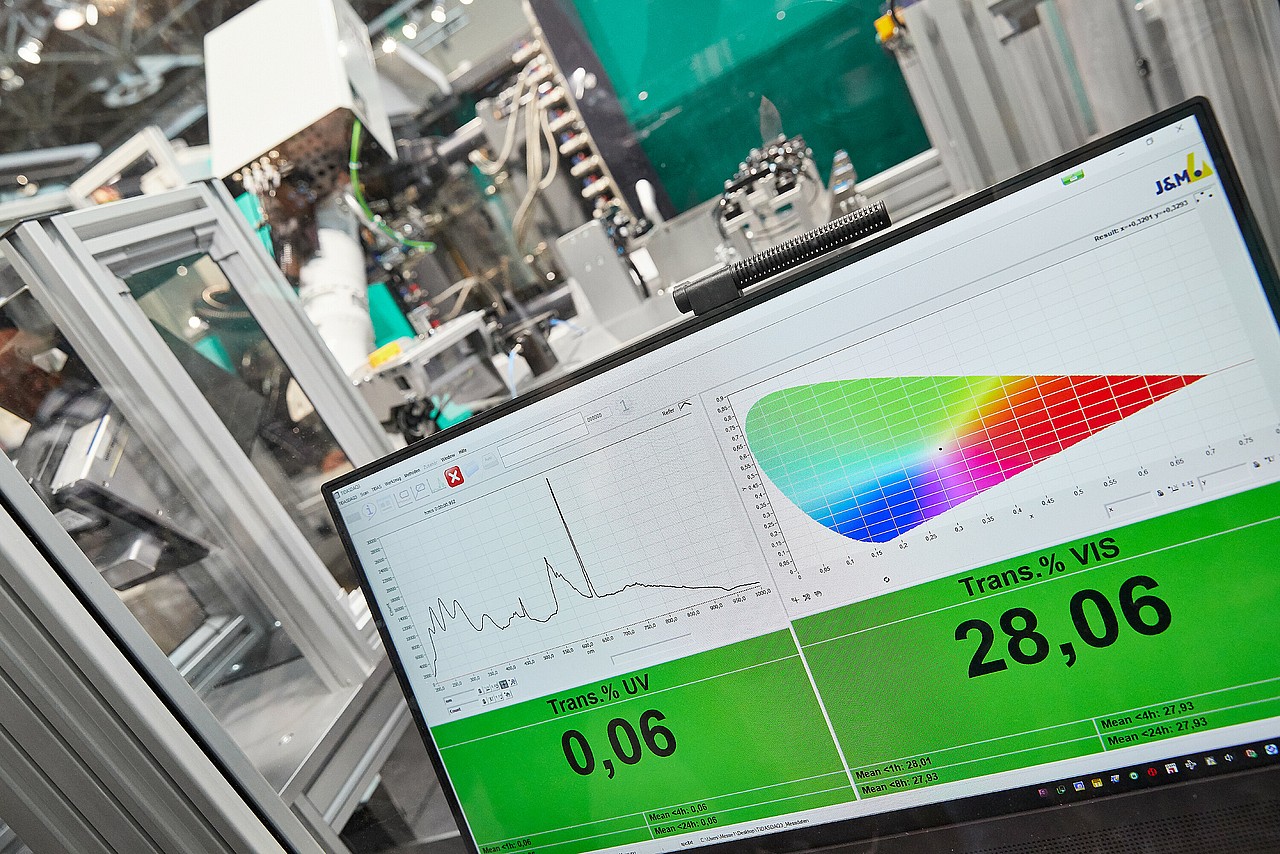

ARBURG Turnkey Control Module (ATCM)

The ATCM SCADA system stores part-specific data from the injection molding process and combines it with the results of optical characteristics check.

Turnkey system

The example shows the potential that lies in the combination of plastic-compatible product design and automated production: The one-piece glasses made of PA12 of filter category 2 are efficiently manufactured in one step without assembly.