Customized

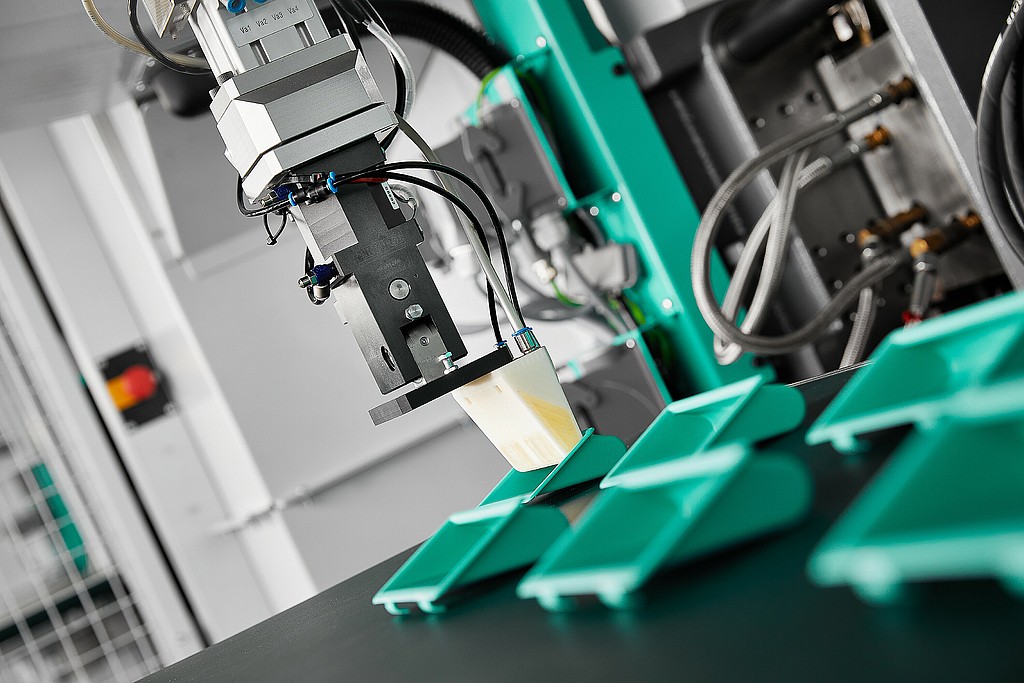

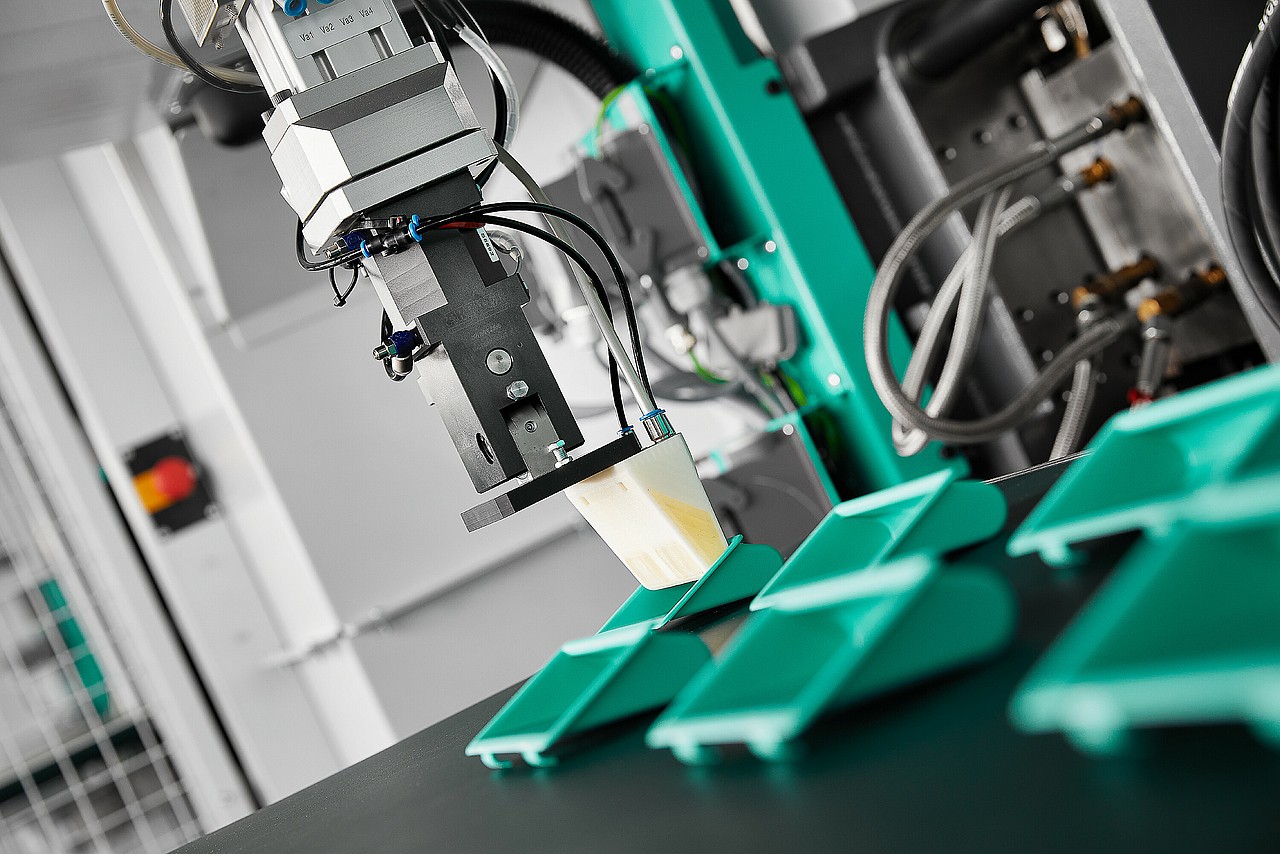

In the ARBURG Plastic Freeforming (APF) process, operating equipment such as robotic grippers can be produced economically and quickly from standard plastics.

Hard/soft

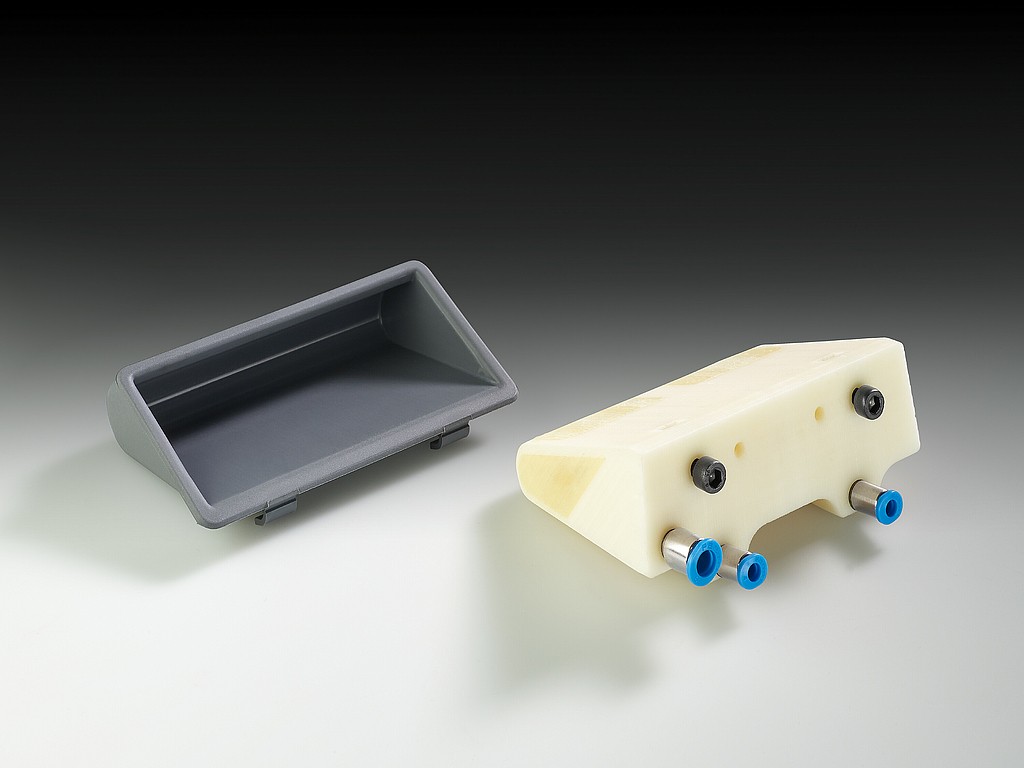

Hard/soft combination: The freeformer additively manufactures a gripper from a dimensionally stable housing and a soft TPU nozzle closure.

Elastic

In order to remove grip plates from the injection mold with a positive fit, the gripper's TPU nozzle closure is expanded using compressed air.

ARBURG solutions used

freeformer 300-3X

The freeformer 300-3X additively manufactures a two-component gripper from PC/ABS and TPU. The result is a resilient functional component in hard/soft combination.

MULTILIFT V

Grippers, assembly devices and other operating equipment can be additively manufactured in a cost-effective way from a batch size of 1. The MULTILIFT V is equipped on demand with a customized gripper.

THERMOLIFT

In ARBURG's own automated injection molding production facility, the 2-component gripper removes grip plates that are installed in THERMOLIFT granulate dryers and conveyors.

APF process

With the ARBURG Plastic Freeforming (APF) open system, the user is in control of the process. Layer separation, droplet size and parameters can be selectively adjusted and optimized.