Preventive

HIV protection: A production cell around an electric ALLROUNDER 520 A mass produces active ingredient implants made of LSR.

Hygienic

The electric injection molding machine in stainless steel version is specially designed for clean room applications.

Responsible

As primary contractor, ARBURG bears responsibility for the complete production cell. This operates directly in a clean room.

ARBURG solutions used

ALLROUNDER 520 A

At the heart of the turnkey system is an electric ALLROUNDER 520 A. Special clean room features include the encapsulated mold area, clean-air module and easy-to-clean stainless steel panels.

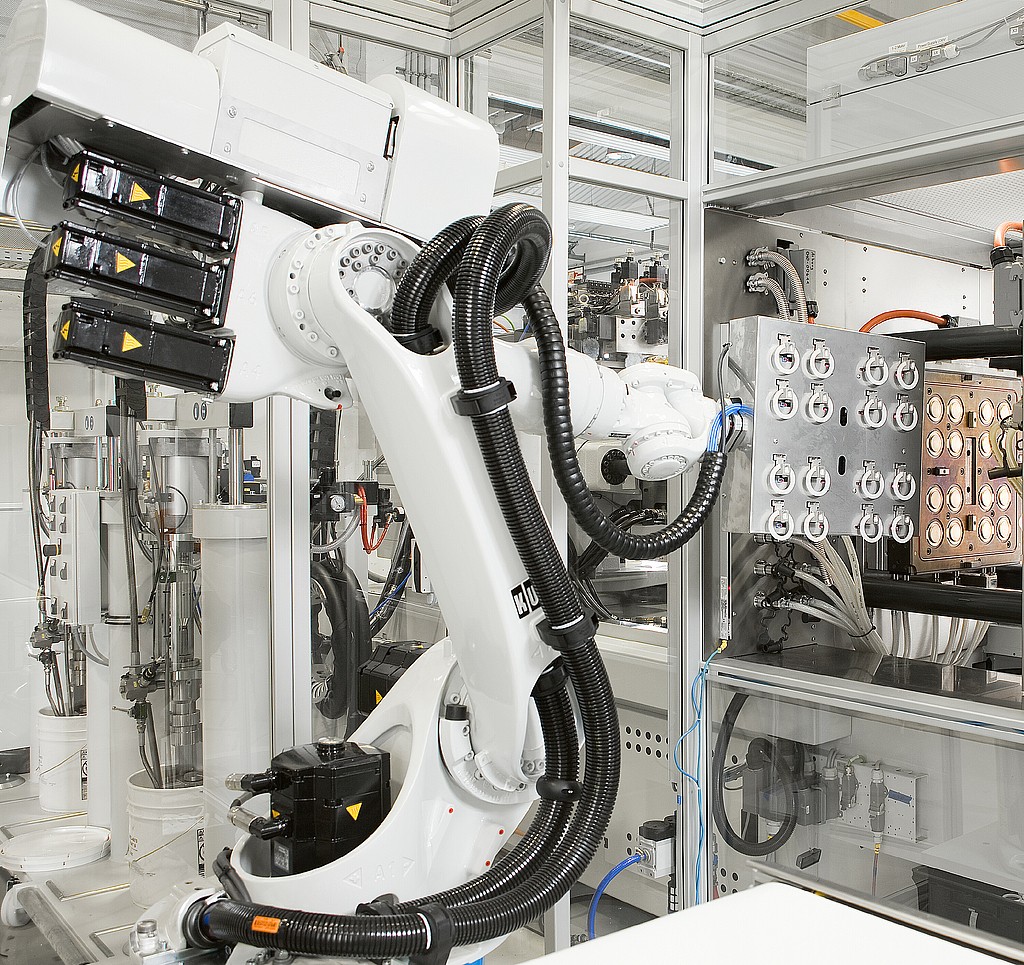

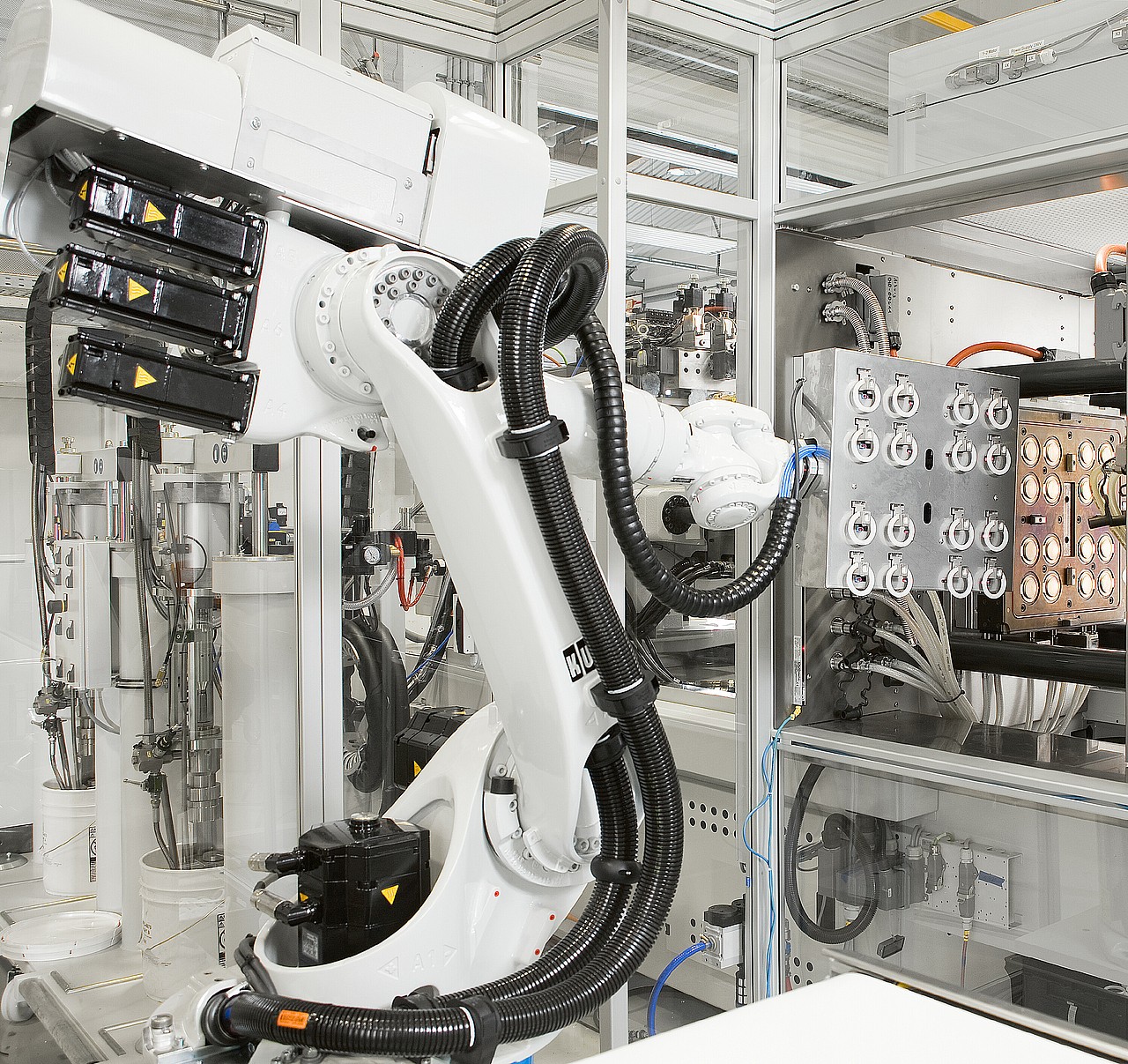

Six-axis robot

A six-axis robot, which is easily and safely programmed using the implemented SELOGICA user interface, removes the vaginal rings from a stripper plate.

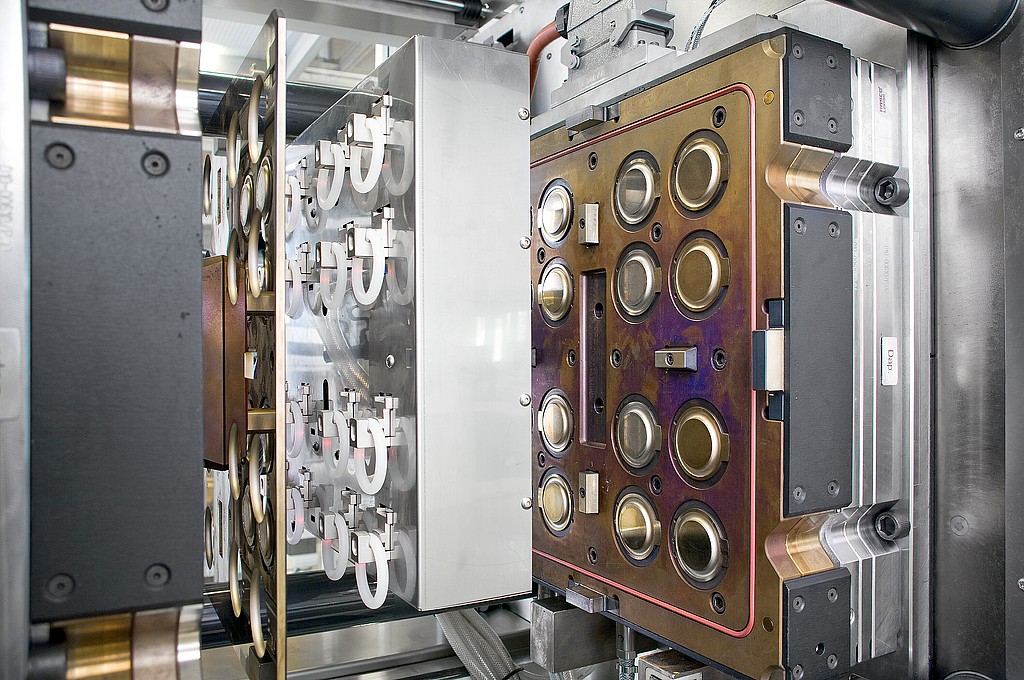

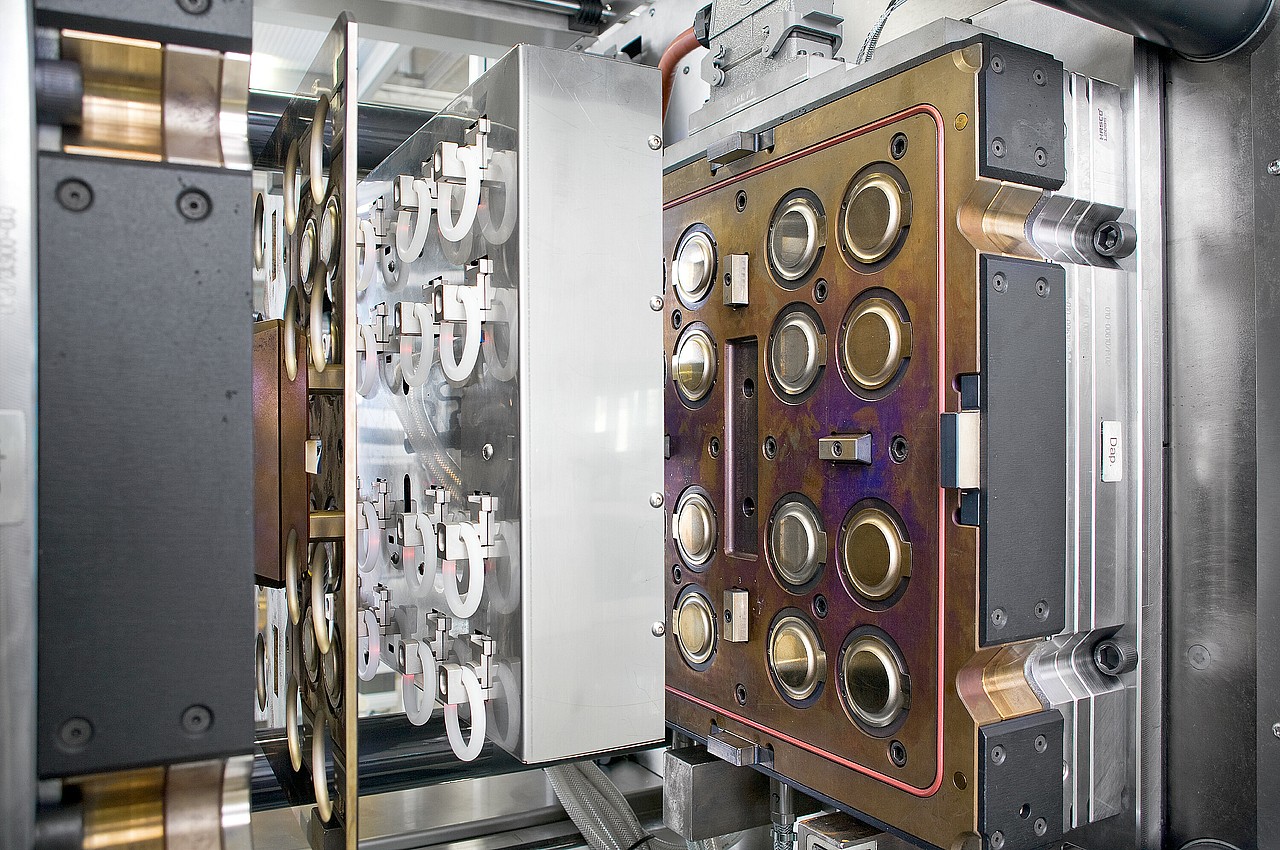

Silicone injection molding (LSR)

16 vaginal rings made of LSR that deliver pharmaceuticals in a controlled manner are created in a single work cycle. The most important quality-related factor is the correct combination of dosage volume and holding pressure. The part tolerance is 0.1 mm.

Clean-room technology

Machine and automation are overbuilt with clean-air modules including ionization. The clean room cell complies with both the ISO 13485 guidelines and the FDA specifications.