Benefits at a glance

Free

Powder injection molding (PIM) is a technology that allows you to produce highly complex components made of metal (MIM) or ceramics (CIM).

High-quality

ARBURG attaches great importance to reproducible and stable production processes, as defects in the molded part can't be eliminated by downstream debinding and sintering.

Tested

Test suitable feedstock mixtures, from preparation to binding and sintering of molded parts – do the test with us in Lossburg. We are also happy to use your molds.

Expandable

Do you have an ALLROUNDER at your company? Then it's also basically suitable for powder processing. We will tailor the technology to your individual requirements.

Benefits of powder injection molding

In series

In series

Injection-molded parts made of metal or ceramic in sophisticated geometries can be produced precisely and economically, in high quantities, always to a high standard of quality and reproducibility.

Injection compression molding

Injection compression molding

Injection compression molding enables directional mold filling without jetting. The ejector or core pulls are actively moved during injection. The injection compression molding is regulated and freely programmable via the machine controller.

Feedstock

Feedstock

Various injection-moldable feedstocks made of fine-grained powder and matching binder on a plastic base preparation to form a homogeneous mass. Users can also develop and produce their own feedstock.

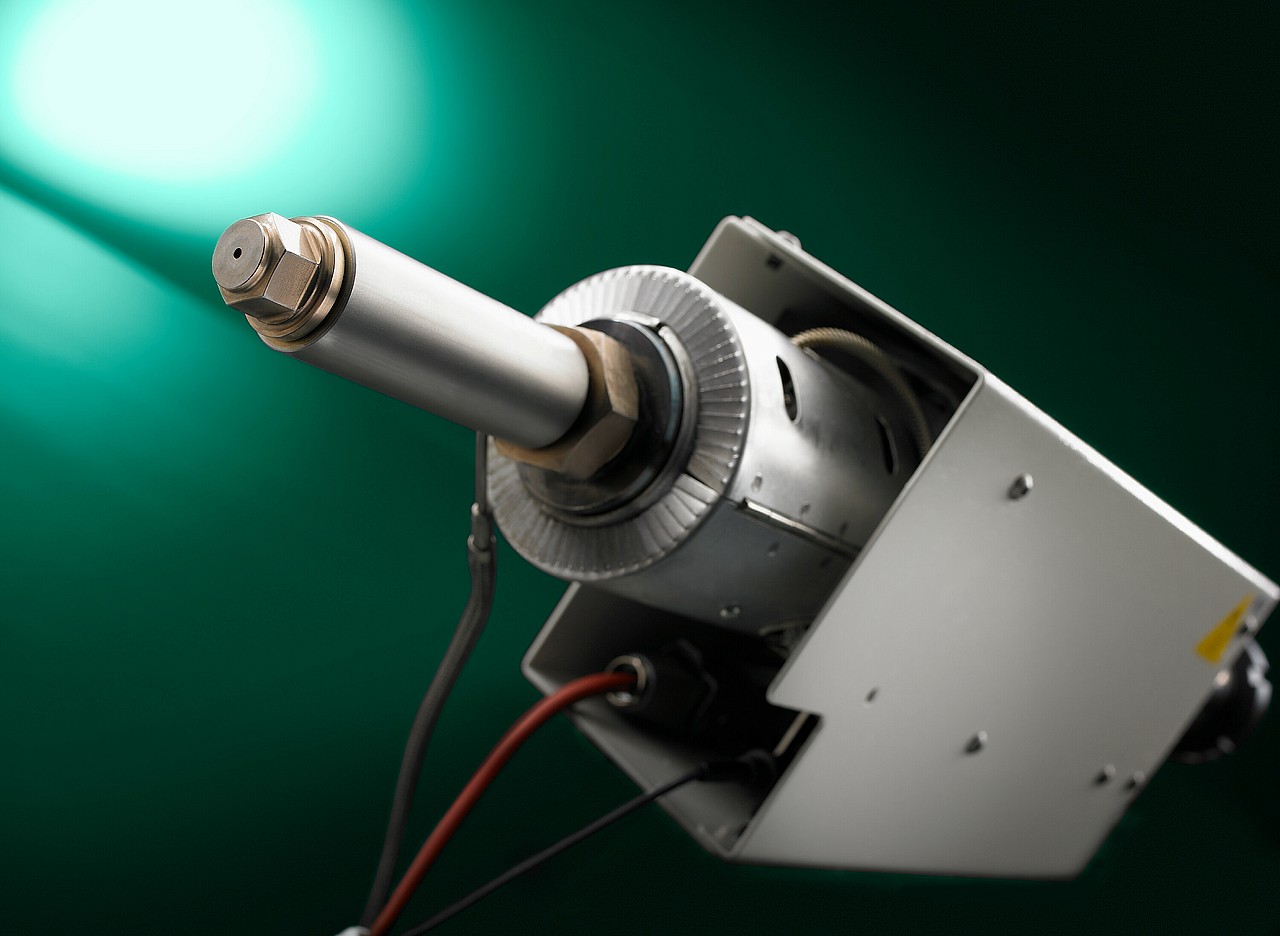

PIM equipment

PIM equipment

Wide range of equipment details for efficient powder processing: e.g., highly wear resistant MIM or CIM cylinder module and extended PIM nozzles.

Application examples

Smartphone

Together with its partner BASF, ARBURG injection molded thin-walled, stress, and segregation-free sample smartphone backs made of metal powder (MIM) for the first time in 2016.

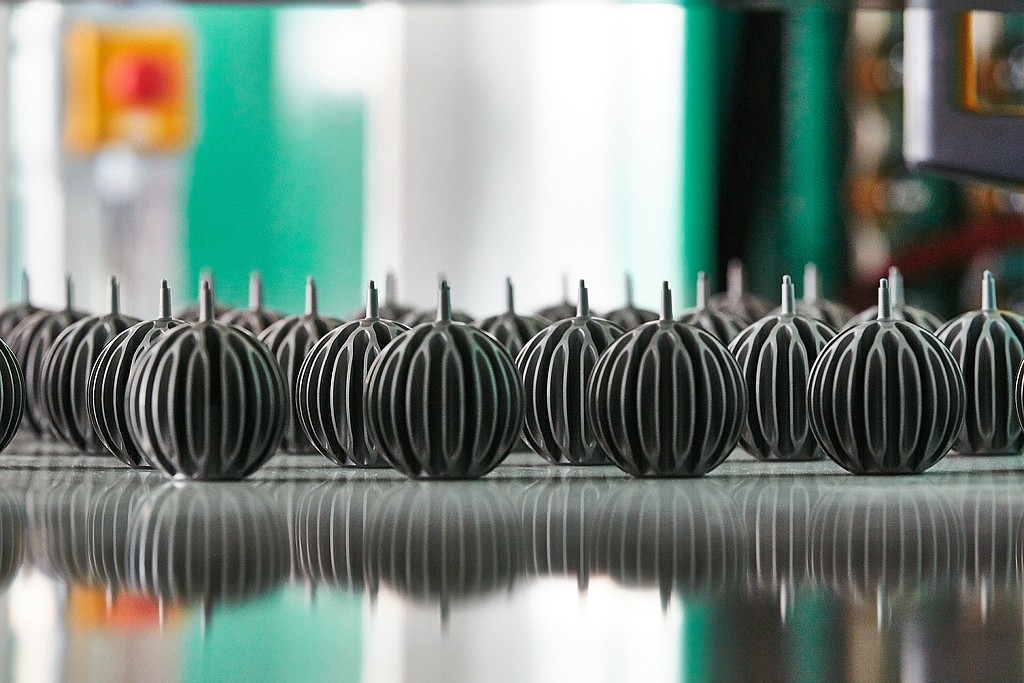

Heat sink

Manufactured close to the final contour, bionically optimized heat sinks for LED lighting make use of the huge scope for forming offered by powder injection molding.

Ferrule

Ceramic ferrule connecting glass fiber bundles for data transmission. Precise execution of the through hole, which is only 0.125 mm in size, is crucial. CIM achieves tolerances of +/- 10 µm.

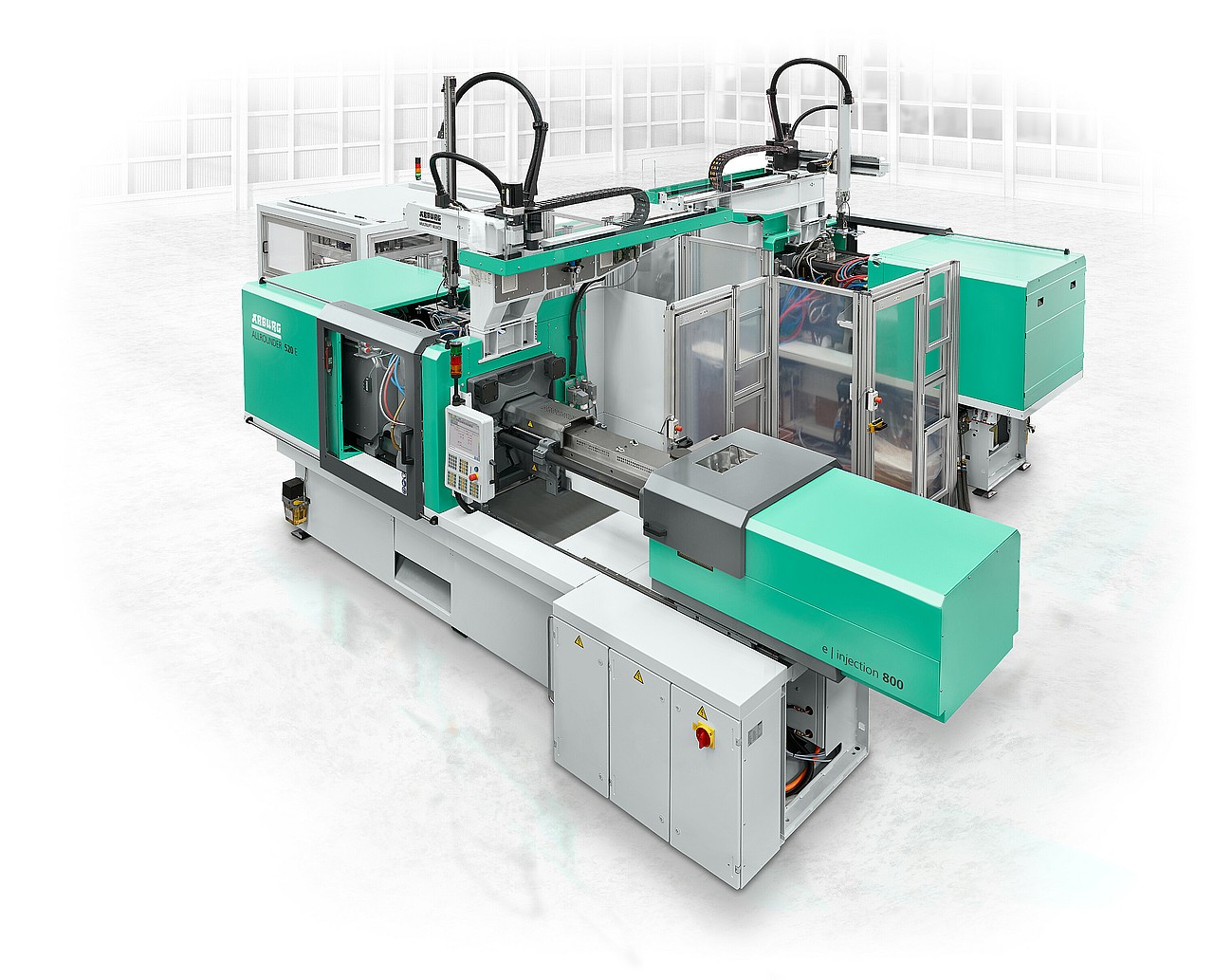

Automated production cells from a single source

Want to increase added value, optimize the injection molding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

This might also be of interest

Take advantage of our expertise – from the design of the molded part to mold and machine configuration. And application technology, for example in our Customer Center.

Whether in injection molding or additive manufacturing: with our machines, you can process all commercially available plastic granules and original materials.

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.