Open

With the open freeformer system, you have the process control in your own hands and can specifically adjust and optimize layer separation, droplet size and parameters.

Original

With the freeformer, you can use the same plastic granules as for injection molding. Use a wide range of certified original materials.

Flexible

Components made of TPE or in hard/soft combination. Complex geometries or integrated functions. Working in clean rooms. For all this and more, our freeformers are the right solution.

freeformers from ARBURG

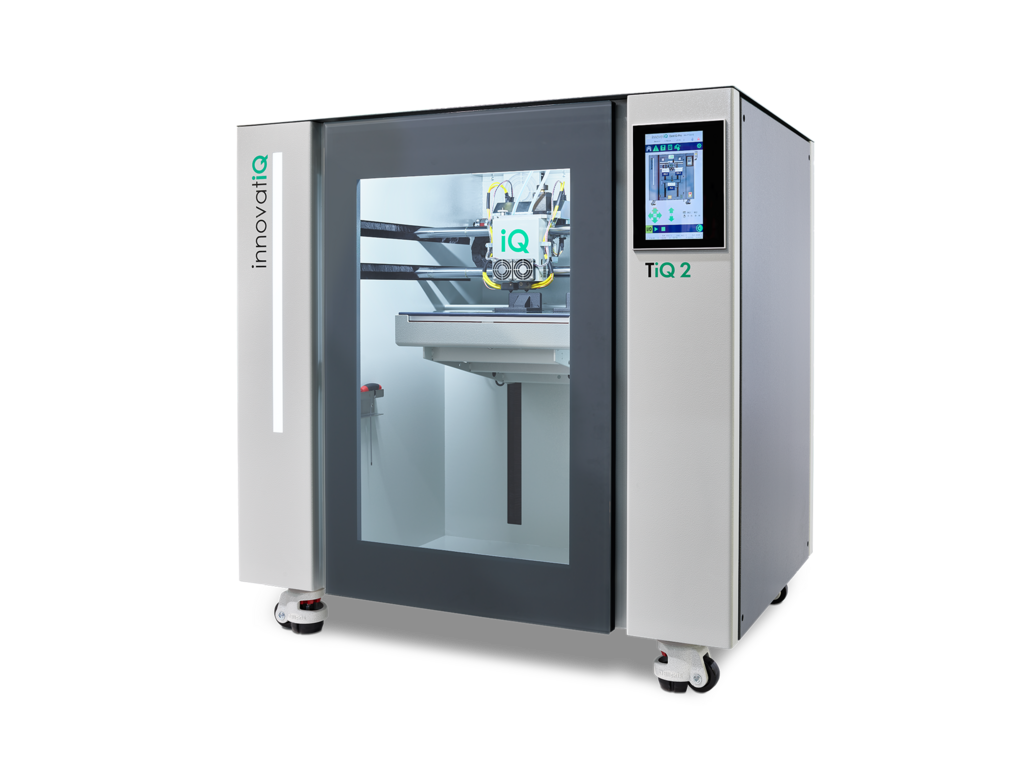

Machines

Benefits of freeformers

Complex

Complex

Up to three discharge units, combination of hard/soft or of materials and colors, support materials for complex geometries

Emission-free

Emission-free

Build chamber in stainless steel, residue-free process, water-soluble support material, no manual finishing work, also designed for work in clean rooms

Efficient

Efficient

Use of certified original materials, processing of specific material compounds, constantly growing material database, qualification of own materials, material dryer, optimized software

Easy to understand

Easy to understand

High-end control system with multi-touch screen in industrial PC technology, easy-to-understand, intuitive user interface, automated slicing software

High-quality

High-quality

High-performance components: servo motors, integrated material preparation, control cabinet "made by ARBURG"

Areas of application

Medicine

With freeformers and the APF process, you can additively manufacture medical technology products, even from qualified original materials. With total freedom: biocompatible, sterilizable, implantable and even resorbable.

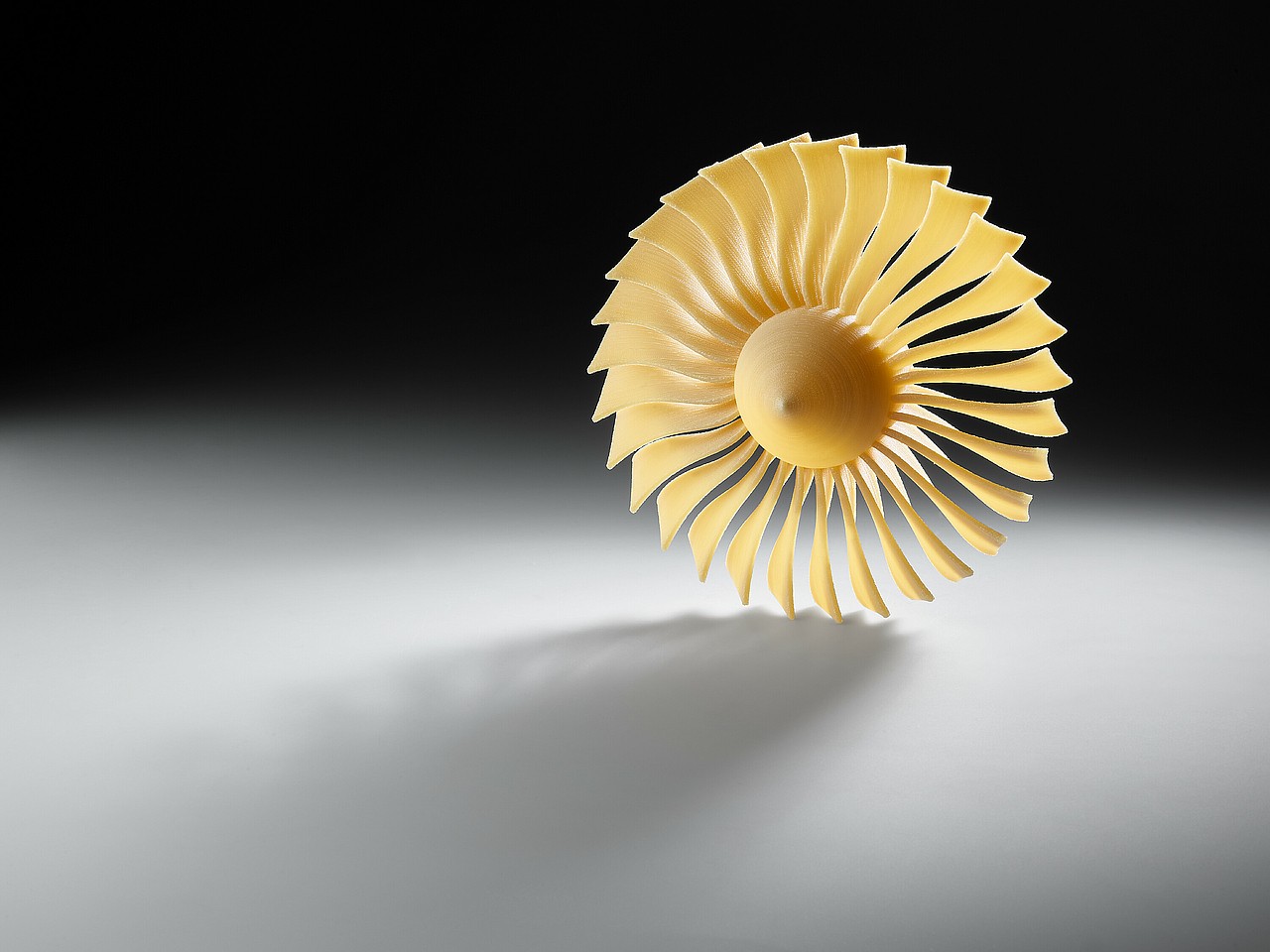

Mobility and lightweight construction

Production of honeycomb structures and bionically optimized components on freeformers. Flexible functional components made of original soft materials. Not only saves you weight, but costs and time as well. In terms of both material and equipment.

Aerospace

Lead the way. With your additive manufacturing, you are way ahead in lightweight construction. With a high degree of freedom, resource conservation and sustainability. When processing high-strength, high-temperature plastics.

Consumer goods and packaging

Mobile phone covers, flower vases, spectacle frames and shoe soles – manufacture additively personalized products for the consumer goods segment. The benefit for you: a functional component in no time, plus reduced costs in the process.

Electronics

Multi-material processing, flame protection, function integration, miniaturization or the combination of various processes. freeformers can meet all these requirements. Even if you want to process electrically conductive materials, this is not a problem.

This might also be of interest

From practical experience – for practical use. That's how we share knowledge. You benefit from our expertise. Targeted, fast, and cooperative. With our machines, for your purposes.

When you work with freeformers in medical technology, many things become easier. Work with original materials that are biocompatible, sterilizable, implantable or resorbable.

The multitude of sectors, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

Newsletter registration

Want to stay up to date on all things APF and freeformer? Then simply subscribe to our freeformer newsletter. Available in German or English.