Cube-mold technology for two-color flip-top closures

ARBURG solutions used

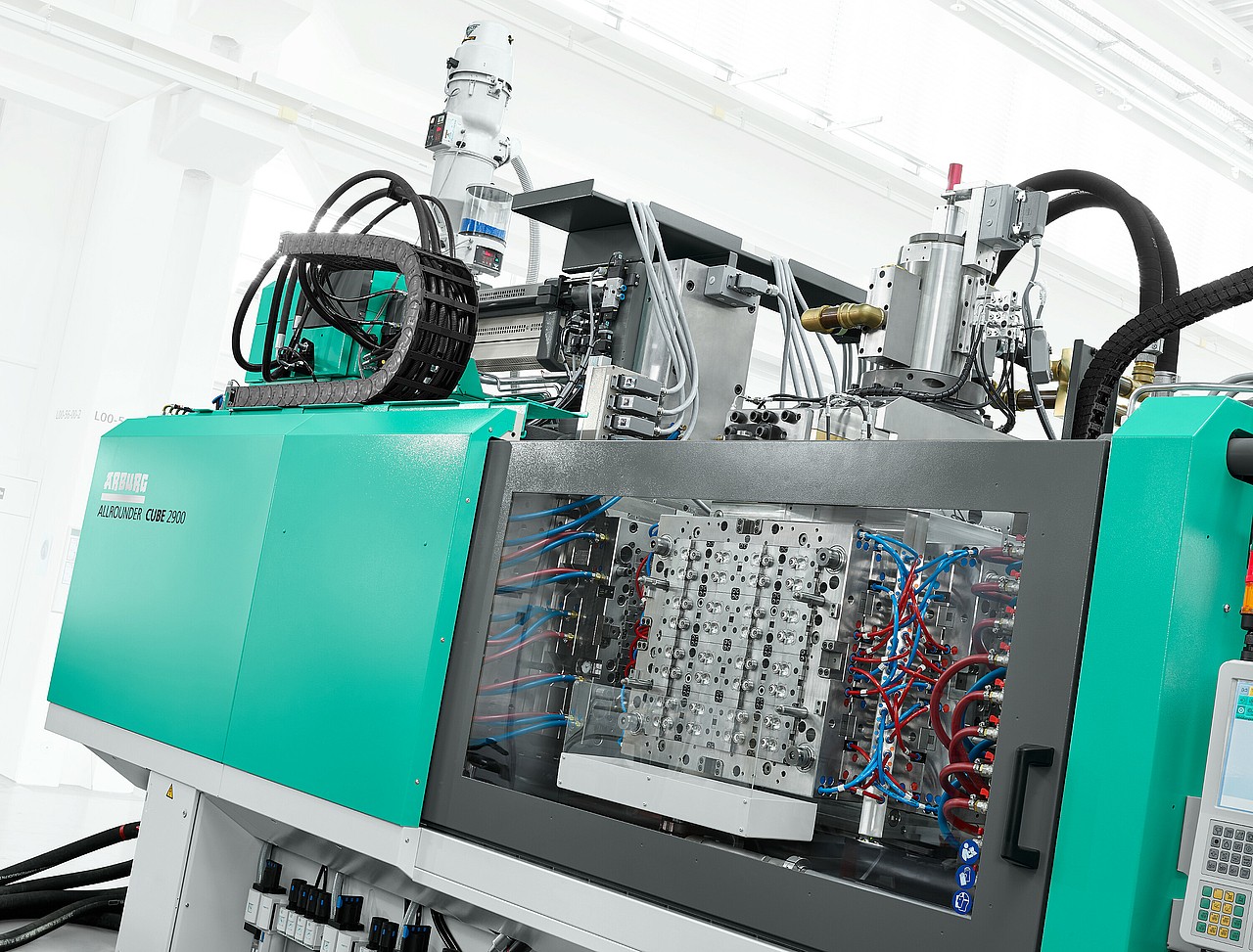

ALLROUNDER CUBE 2900

In the ALLROUNDER CUBE 2900 cube machine with a clamping force of 2,900 kN, the servo-electric toggle-type clamping unit and servo-electric cube turning enable fast cycles with reduced energy requirements.

Injection units

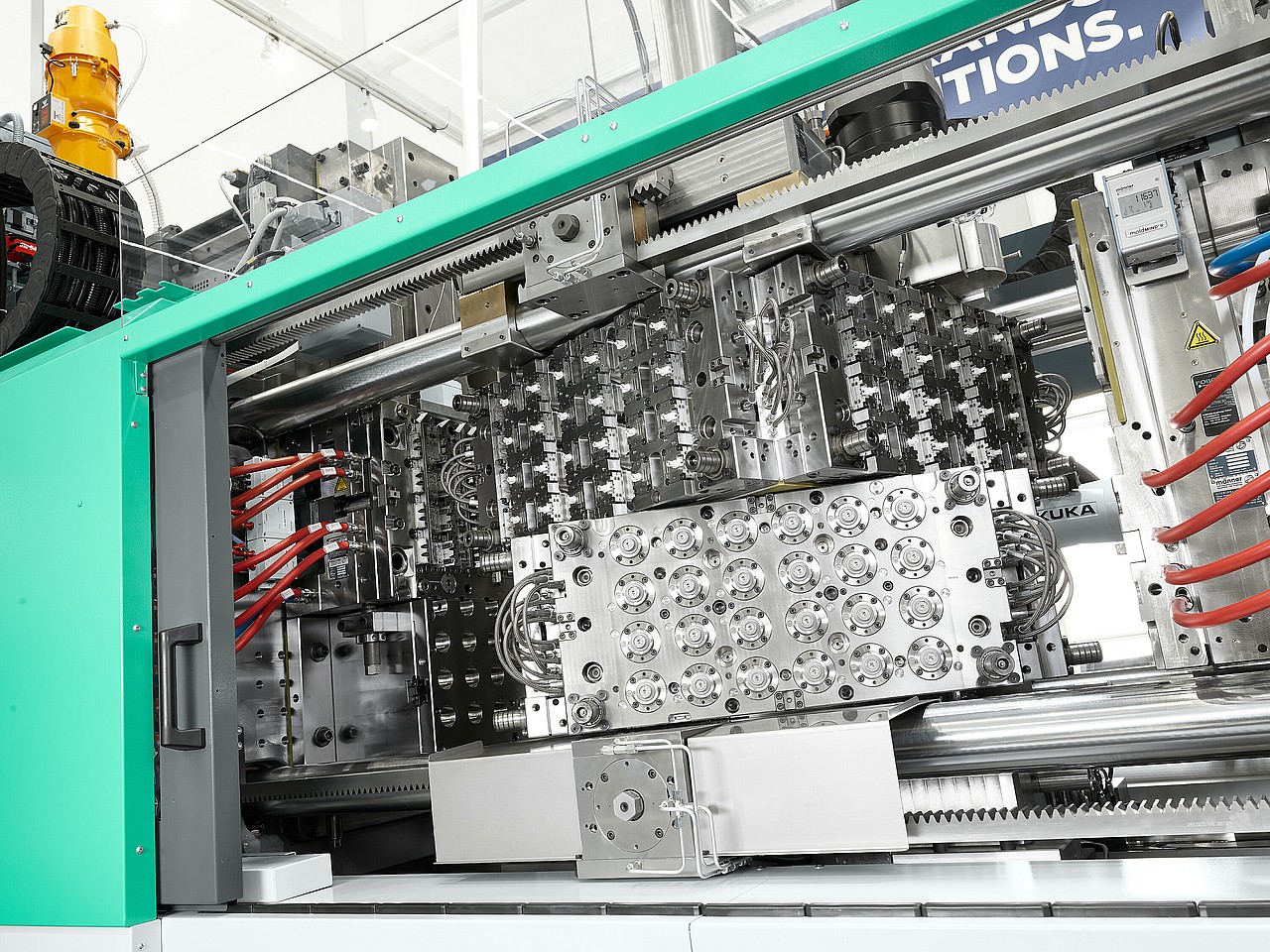

For injection molding of the two different colored PP components, two independently moving injection units are arranged horizontally and traveling above the mold mounting platen.

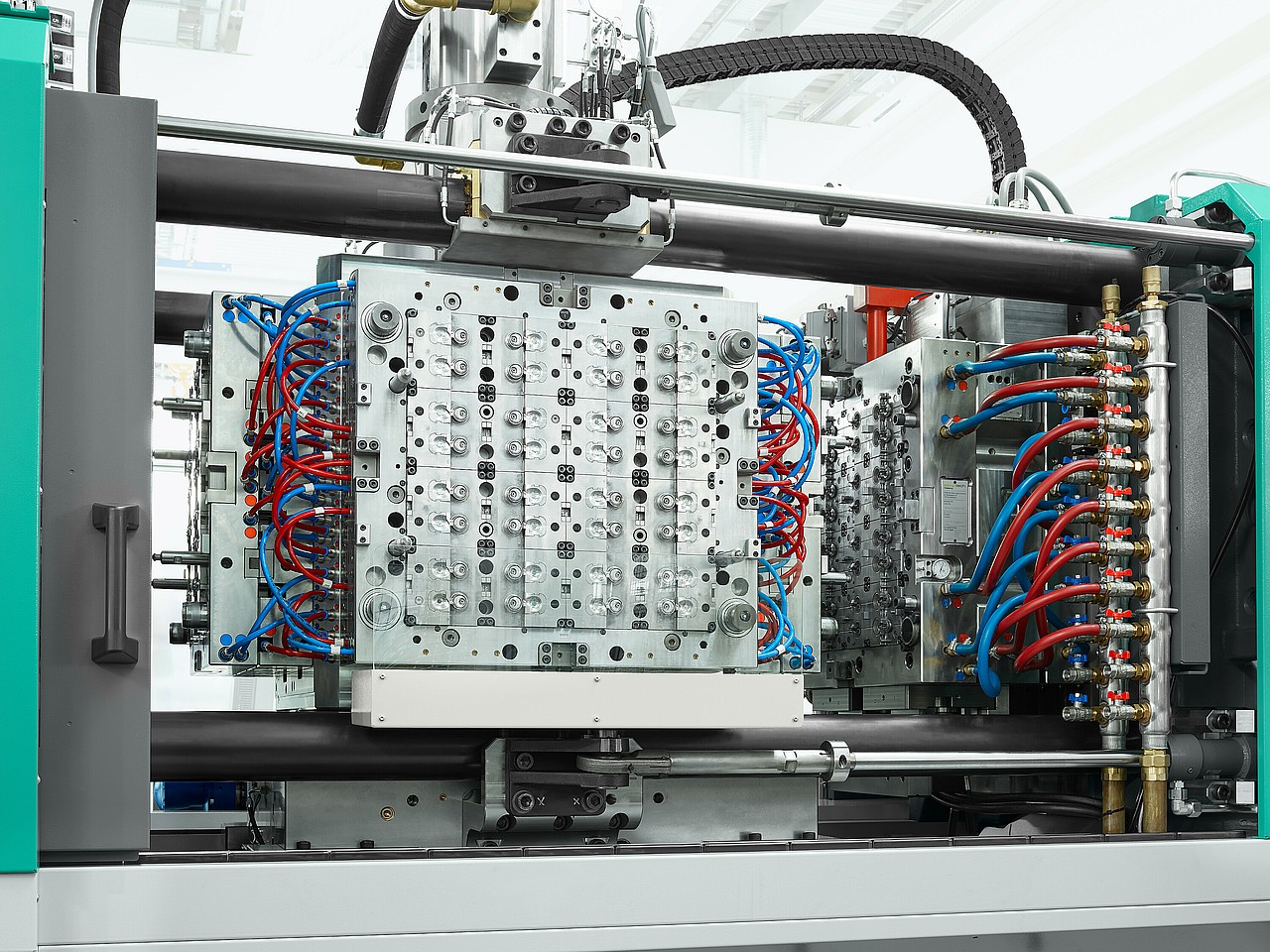

Cube mold technology

With the four cube sides that can be used for production, mold filling, cooling and part removal run simultaneously. In addition, twice the number of cavities are available with the same mold mounting surface.

Turnkey solution

ARBURG implements complete cube systems for the packaging industry with its partner Foboha. The modularity of the CUBE series and the "smart" control system enable precise matching to the mold technology.