High-temperature plastics processing

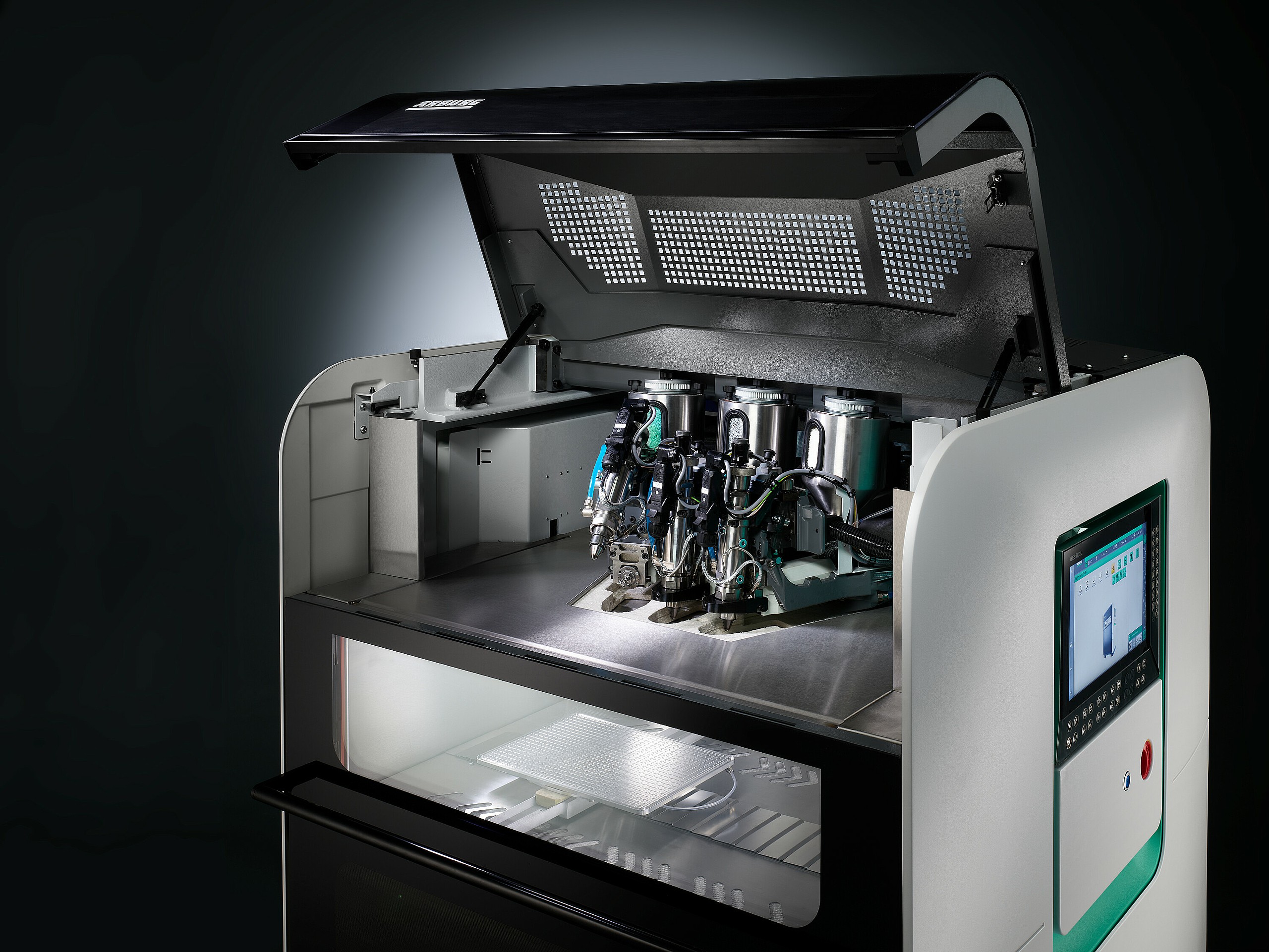

At NPE 2024, a high-temperature freeformer 750-3X will demonstrate how complex functional components can be printed reliably and reproducibly from certified original plastic pellets. For the processing of high-temperature material, the temperature of the build chamber can be raised to up to 392 °F (200 degrees Celsius; plasticizing takes place at a maximum of 842 °F (450 degrees Celsius). The high-end machine has three discharge units and, from the outside, is indistinguishable from the freeformer 300-3X. However, at around 116 square inches (750 square centimeters), the part carrier is around 2.5 times larger. This allows larger functional components to be produced and small batches to be additively manufactured on an industrial scale. A compact melt pressure generator, which produces tiny droplets at a frequency of up to 400 hertz, is used for precise dosing and injection. The result is 3D-printed components that are comparable in quality to injection-molded parts