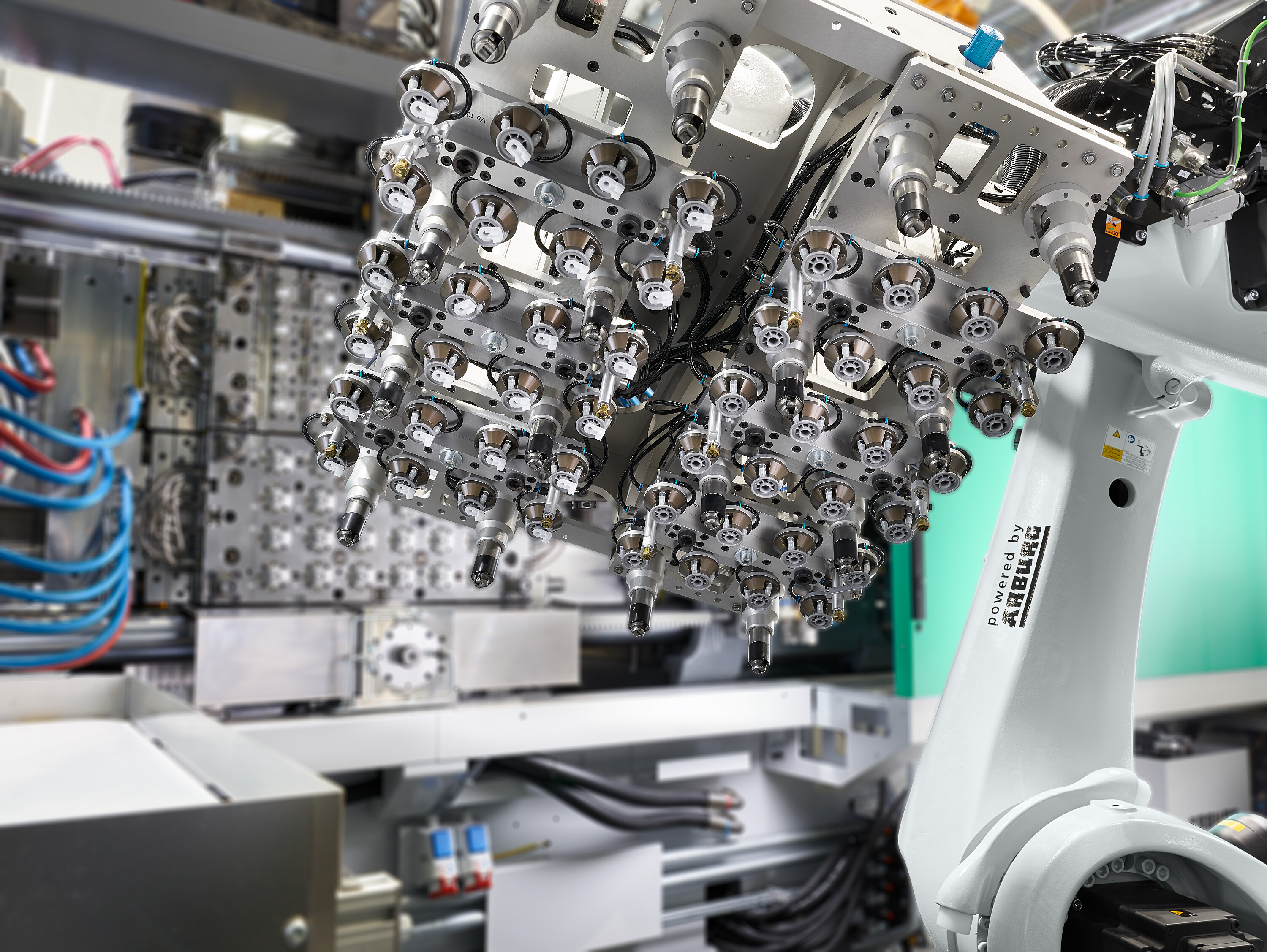

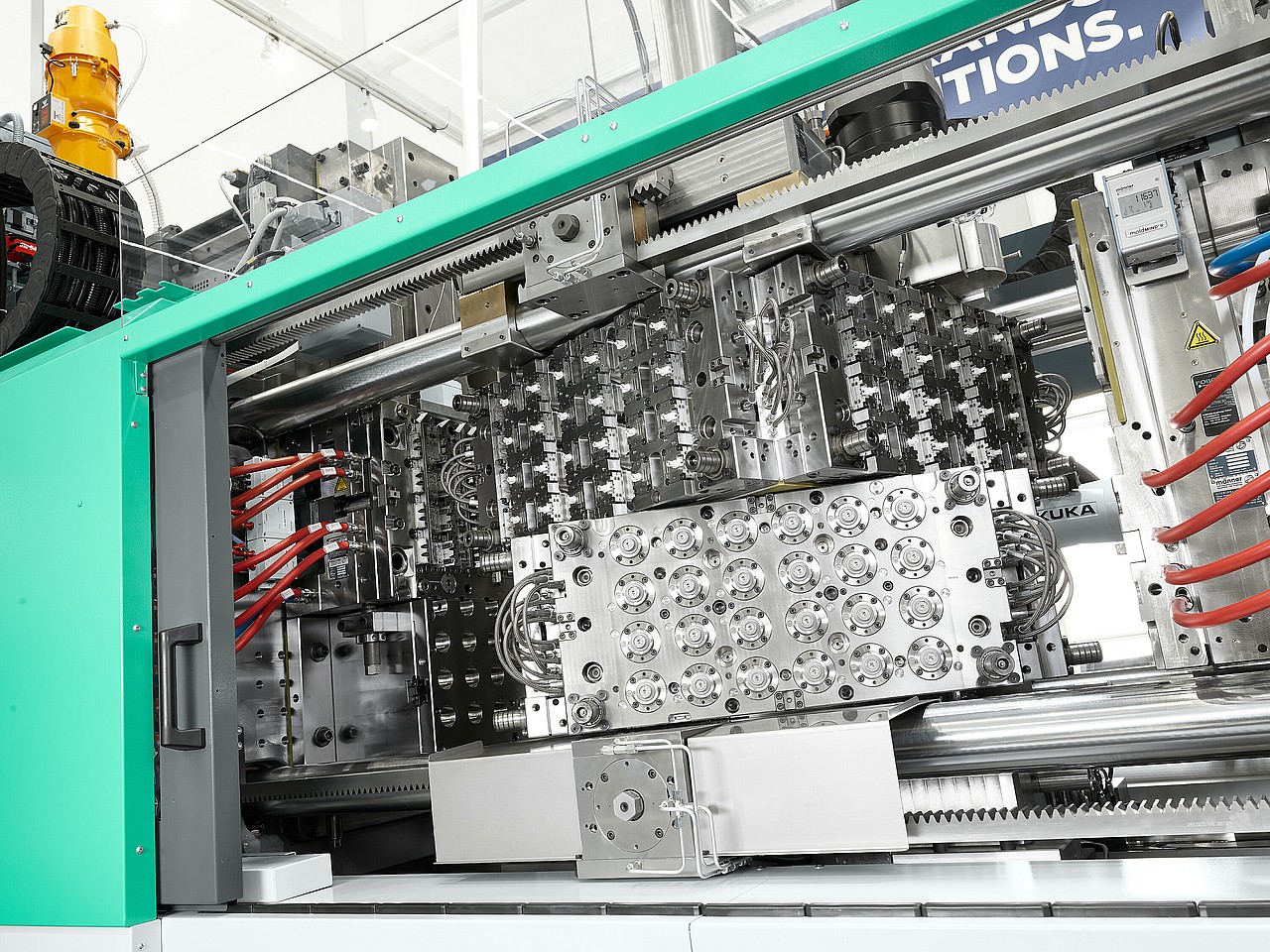

The Reverse Cube system with a 24+24-cavity mold and the ALLROUNDER CUBE with a clamping force of 2,900 kN are precisely coordinated with and adapted to each other in terms of software, automation and QA evaluation, for example. While the PP bushings are molded on the lower half of the cube, the corresponding POM rollers are created opposite on the top. The cube halves then rotate 90° in opposing directions. On the passive cube sides, the molded parts cool down to such an extent that the individual parts can be assembled directly in the mold. This task is performed by a six-axis robot integrated into the control system at the rear of the machine without affecting cycle time. Process monitoring and 100 percent parts inspection are automated.