Numerous innovations and further developments

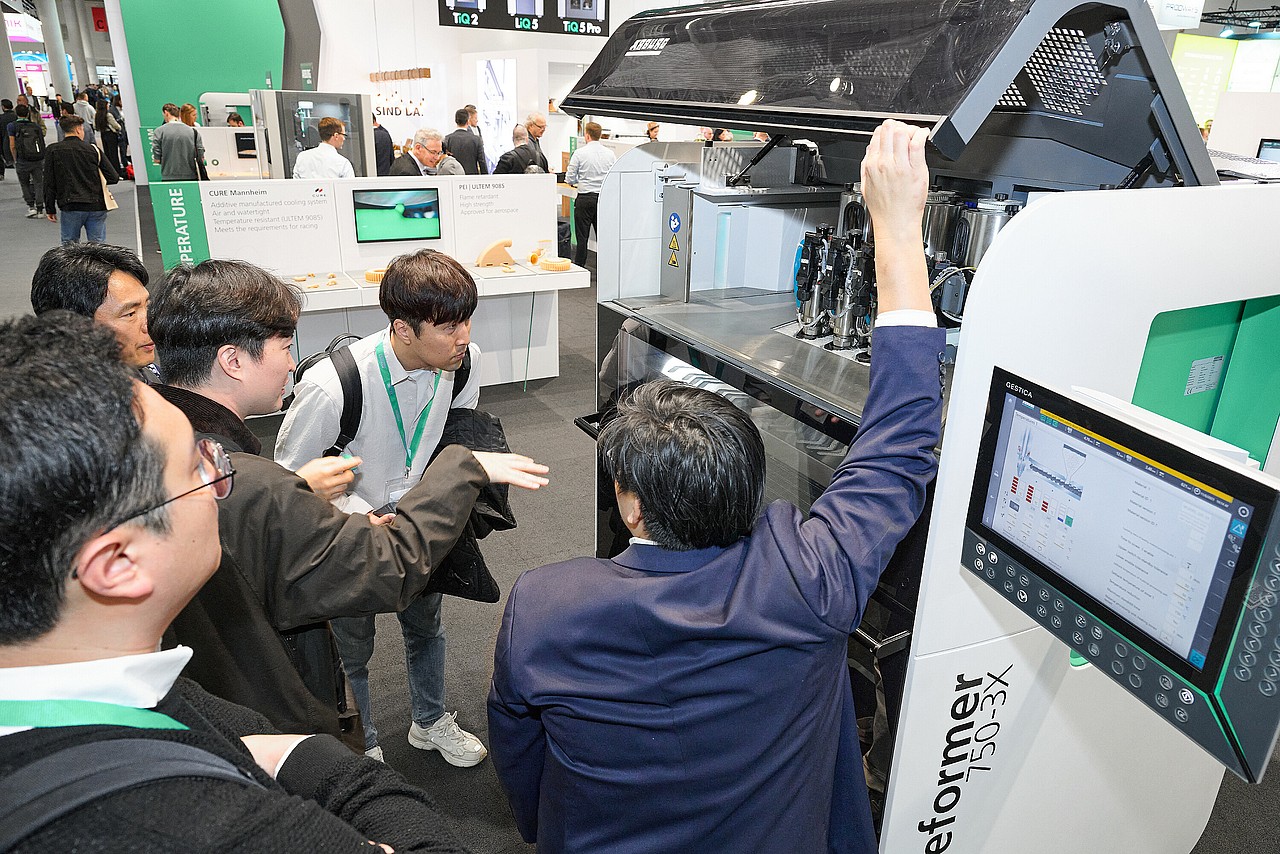

Since autumn 2023 a freeformer 750-3X has been available in a high-temperature version, the build chamber of which can be tempered to 200 degrees Celsius; with plastification of the plastic granules taking place at up to 450 degrees Celsius. The manufacture of geometrically intricate ventilation ducts for aerospace manufactured from original Ultem 9085 was demonstrated as a typical application. Another new development that the ARBURG Plastic Freeforming team is currently working on is the processing of fibre-glass reinforced thermoplastics. As an example, initial first results were introduced using technical parts made from PA with 25 percent fibre-glass.

Equally interesting were personalized multi-material shoe insoles made from flexible TPE and a hard area made from PP, on a standard freeformer 750-3X. This extra soft ARBURG Plastic Freeforming product was manufactured by a freeformer 200-3X from TPE with a sponge structure. At Formnext, 15 small and highly popular hearts, were manufactured in around 90 minutes build time. In the specific customer application, this material is used for personalized breast prostheses.