Two-component eyeglasses as a hard/soft combination

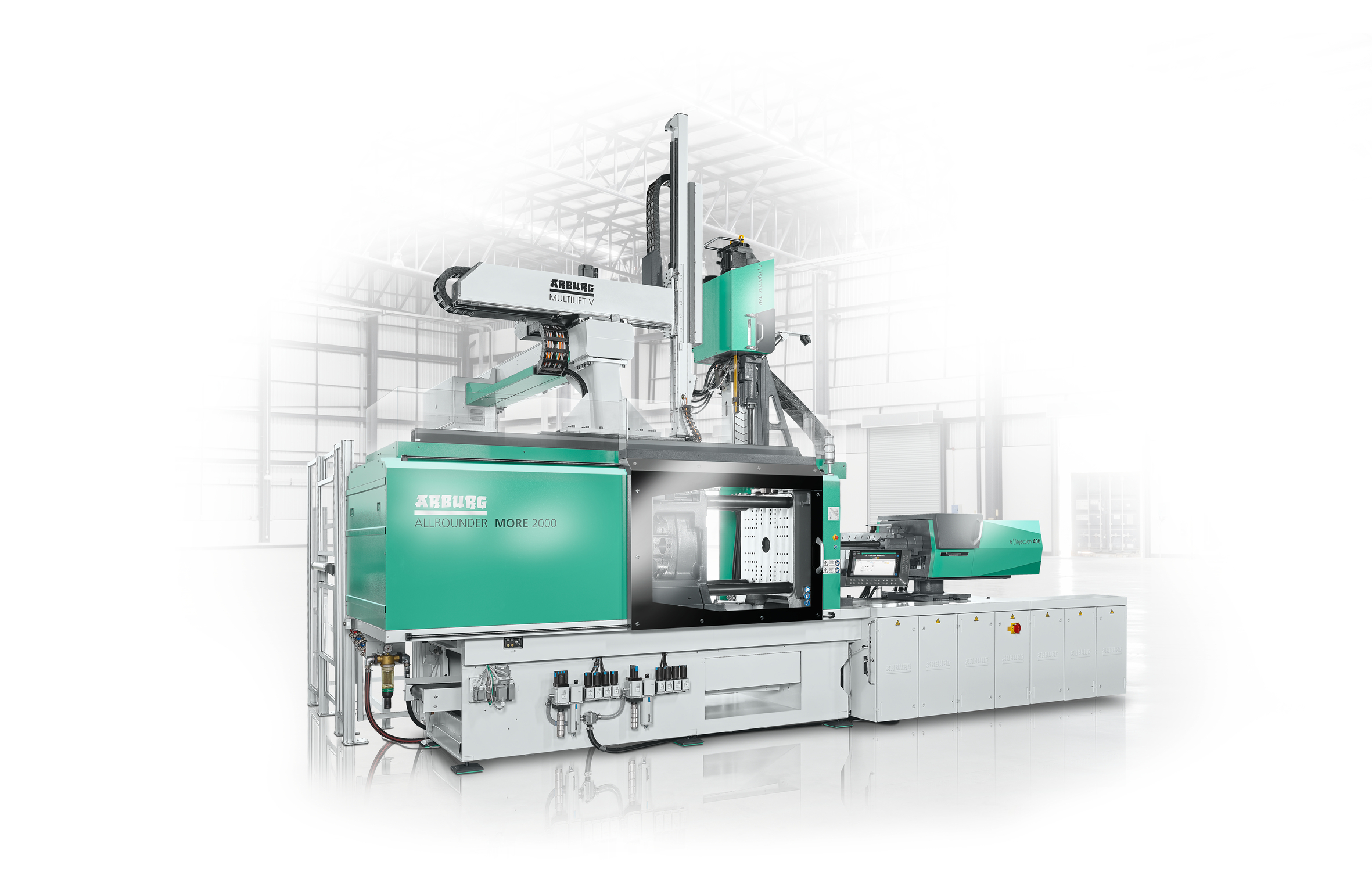

The ALLROUNDER MORE machines are ARBURG's special series for multi-component injection molding. They offer lots more space for molds, rotary units, media connections and a usable ejector stroke as well as numerous optimized features for greater ease of use and simple maintenance. Precision is ensured by a highly dynamic electric toggle-type clamping unit with energy-efficient, liquid-cooled servo motors. At NPE 2024, an ALLROUNDER MORE 2000 with 220 tons (2,000 kN) of clamping force and two electric injection units will process optical liquid silicone (LSR) and thermoplastic (PA). The two-component eyeglasses are produced in a 1+1-cavity mold in a cycle time of around 85 seconds. First, the vertical injection unit molds the frame made of PA. An index unit then rotates the pre-molded part into the second station. There, a horizontal injection unit adds the soft LSR lens. Part handling is performed by a Yaskawa six-axis robot.