Benefits at a glance

Adaptable

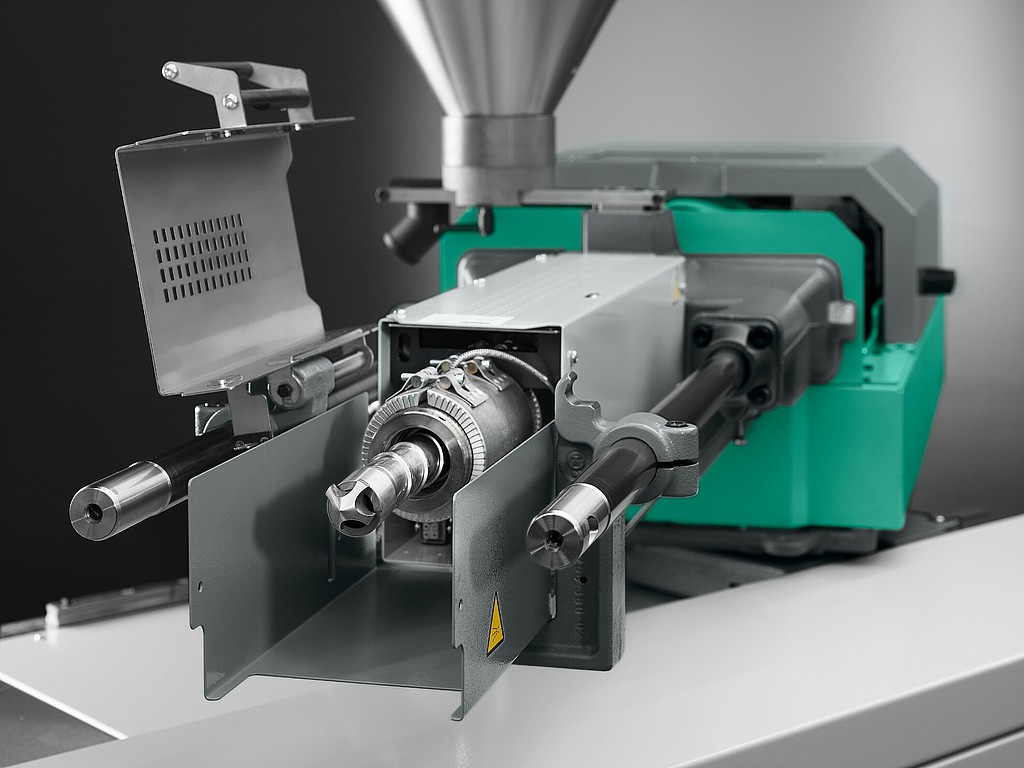

With modular, expandable machine technology and a swivelling clamping unit and reversible injection unit based on the ALLROUNDER principle. So you can also work in the mould parting line.

Expandable

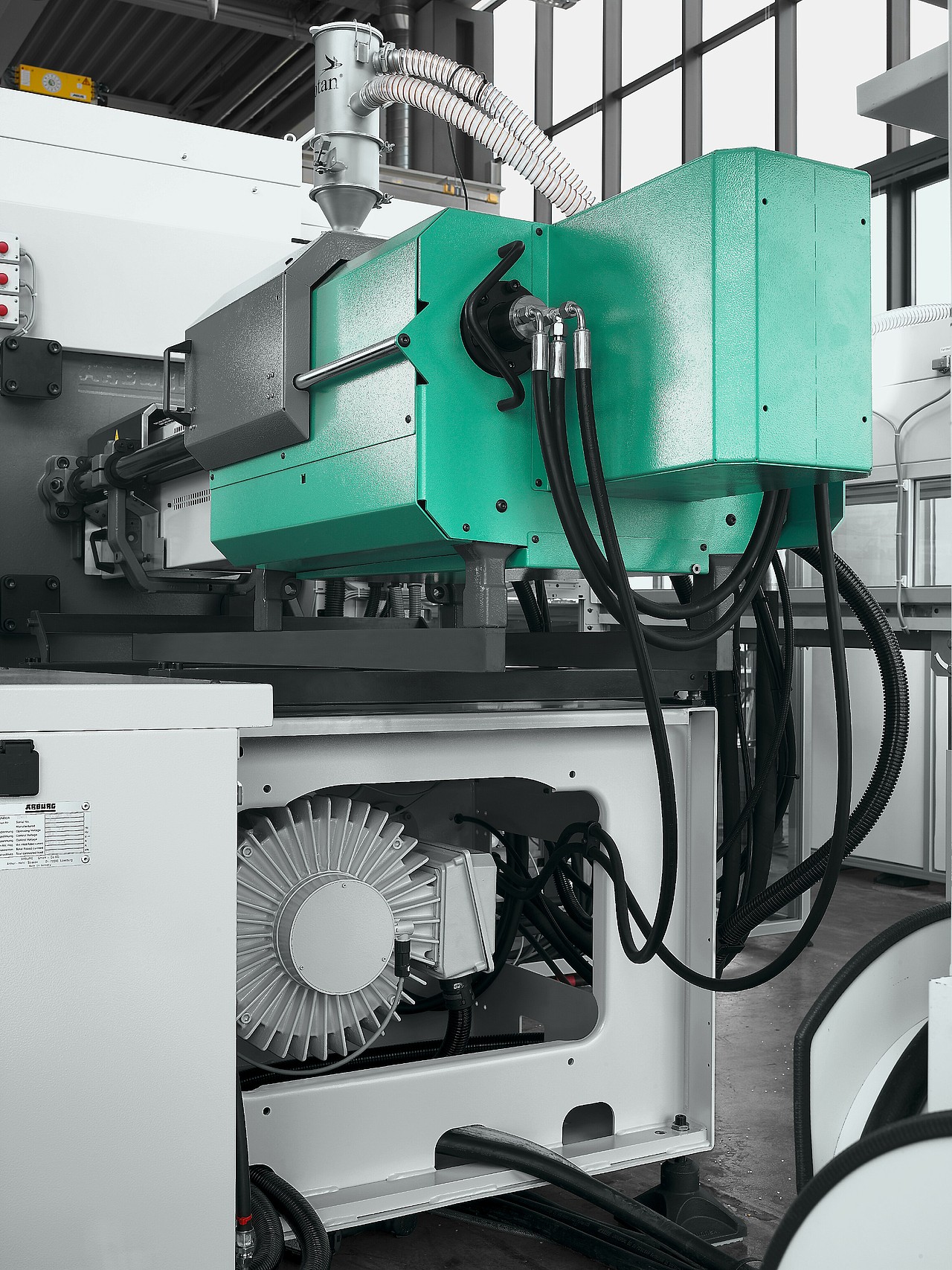

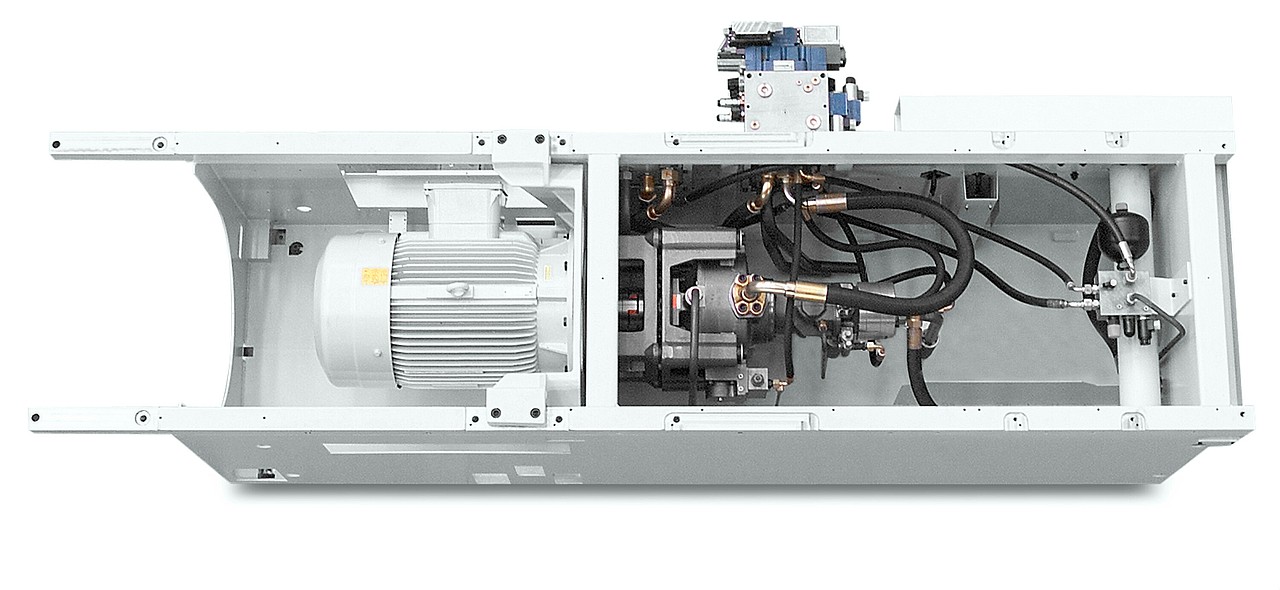

Alternatively with ARBURG servo hydraulics (ASH) productivity package or hydraulic accumulator technology: We have the right hydraulic equipment variants for all injection moulding processes.

Versatile

Are you after the widest possible range of applications and process-optimised solutions? Tell us your requirements and we will put together the ALLROUNDER S that is exactly right for you.

Comprehensive

ALLROUNDER S machines cover a wide range of sizes. And with exactly the flexibility you are looking for. Modularity is key!

Technical data

Part examples

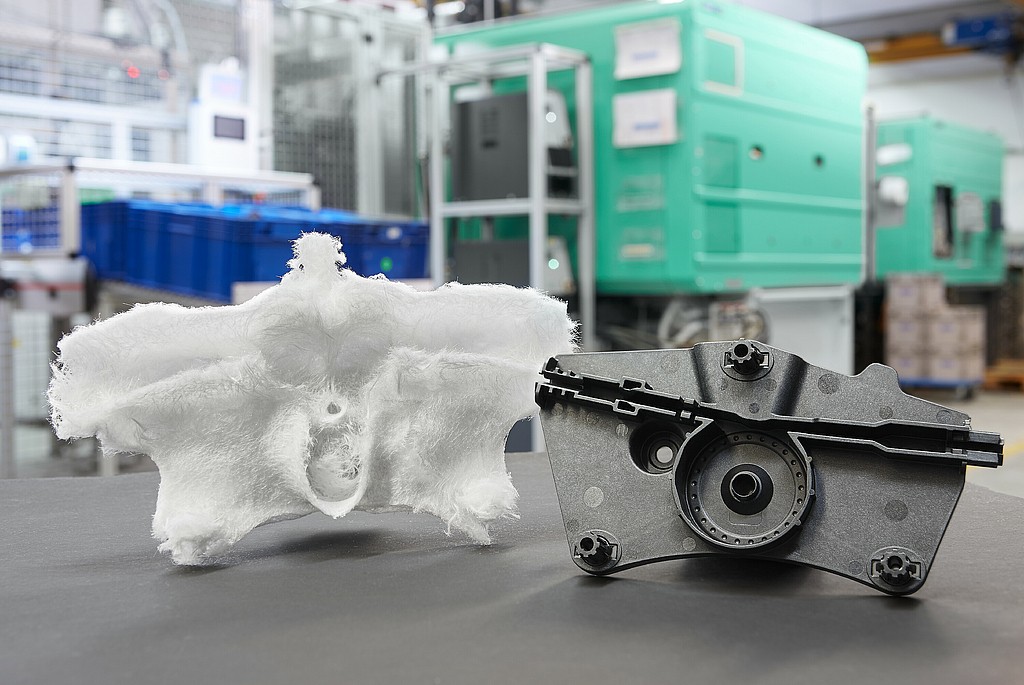

FDC housing

Using fibre direct compounding (FDC) is an exciting alternative to PBT in the field of mobility, among others. For example, to produce stable and lightweight housings made of PP with long glass fibres.

Steering wheel trim

Trims for car interiors – design parts that contribute to a high-quality impression in the vehicle. While PC provides stability, the PC/ABS can be selectively galvanised.

Angle-of-rotation sensor

Three becomes one when the magnetic disc, platform and protective cap are injection-moulded to form a functional angle-of-rotation sensor. There is no need for joining technology or downstream assembly.

Training Courses

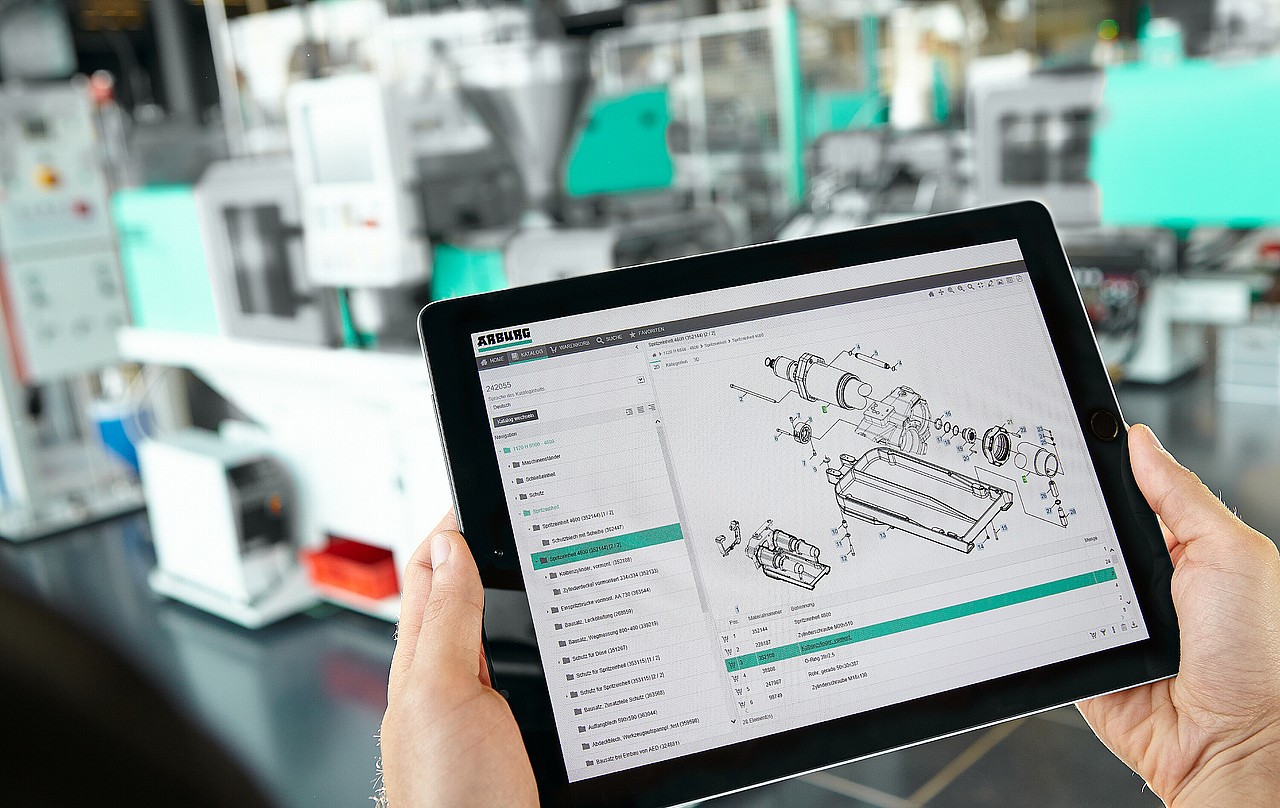

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then use our arburgXworld store for easy and interactive ordering.

This might also be of interest

What do you need for your multi-component technology? Very flexible configurations. That's what the modular ALLROUNDERs are capable of. With our technology and advice, we provide solutions tailored precisely to your production requirements.

If you expect top performance in thermoplastic processing, choose the hybrid ALLROUNDER injection moulding machines featuring a combination of hydraulic and electric axes.

Make use of synergies for your injection moulding operation with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.