Benefits at a glance

Cost-effective

Since they are produced in large quantities, standard thermoplastics are comparatively simple and cost-effective to process.

Malleable

In conventional injection moulding and industrial additive manufacturing, you can work with a wide variety of materials.

Recyclable

Products made of thermoplastic can be recycled after use and the recyclate obtained industrially (PIR) or from end-user waste (PCR) can be returned to the material cycle.

Versatile

Depending on the material chosen, thermoplastics can be soft and flexible, but also dimensionally stable. They are suitable for overmoulding cables or producing "hard" water pipes, for example.

Sample components

Pipette tips

Medical disposables such as pipette tips made of conductive PP place high demands on quality and efficiency. With high-end technology, you can produce over 50,000 pieces per hour.

This might also be of interest

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

Combining moulded parts, colours and materials, rethinking additive manufacturing, realising visions and bringing them into series production – is that your goal? With our technologies and advice, we can provide solutions tailored precisely to your production requirements.

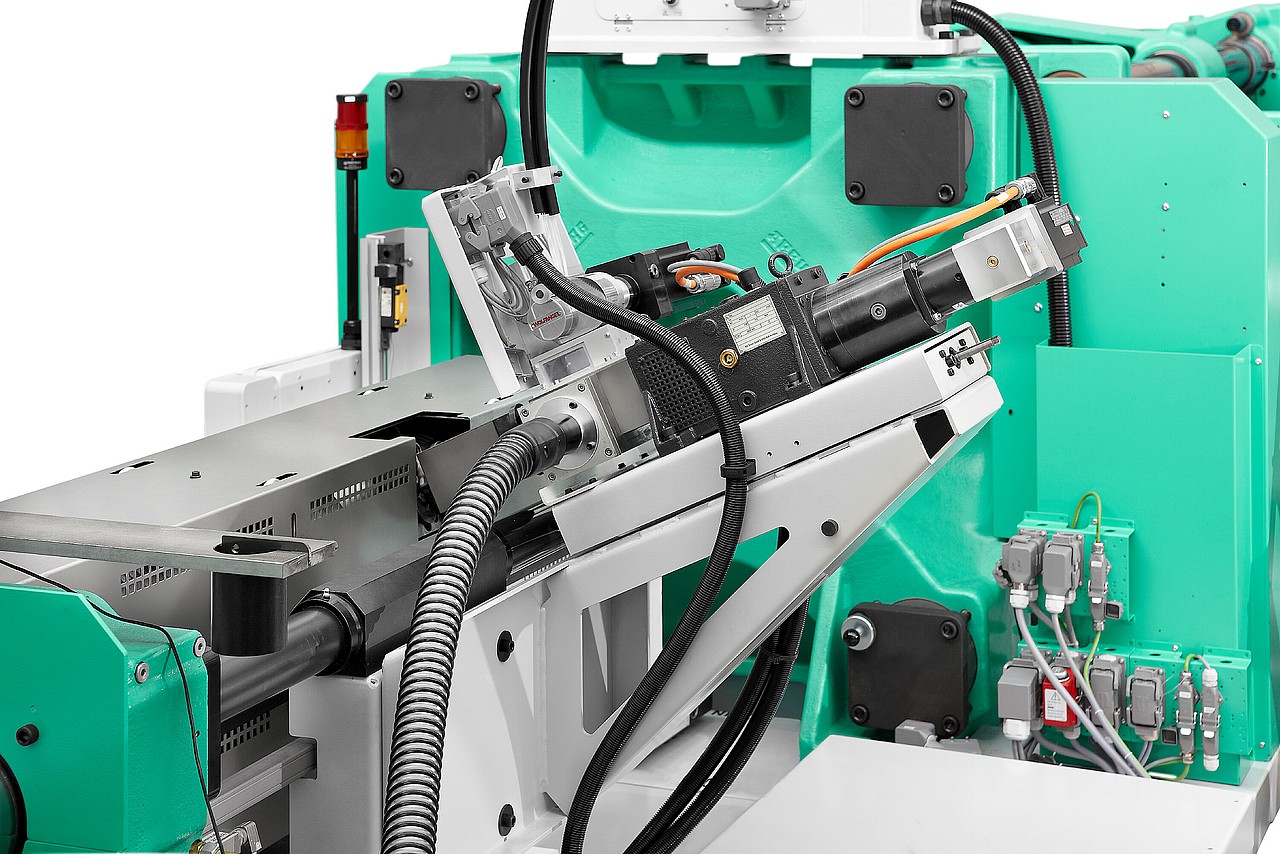

Is injection moulding part of your business? If productivity and efficiency are your goals, opt for ALLROUNDERs! Because the modular ARBURG injection moulding machines meet your requirements to the letter.