Benefits at a glance

Better

Engineering thermoplastics are ideal for technical applications. Benefit from improved material properties.

Resistant

Engineering thermoplastics can resist temperatures of up to around 130 °C. Benefits such as high durability and good viscosity are good reasons for using them.

Resilient

Their excellent mechanical properties make thermoplastics suitable for sliding bearings, rollers and seals, for example, and also for housings, insulators and workpiece carriers.

Widely usable

Engineering thermoplastics can be used as a substitute for many traditional materials. This is because they are abrasion-proof, resistant to corrosion and chemicals, long-lasting and dimensionally stable.

Sample components

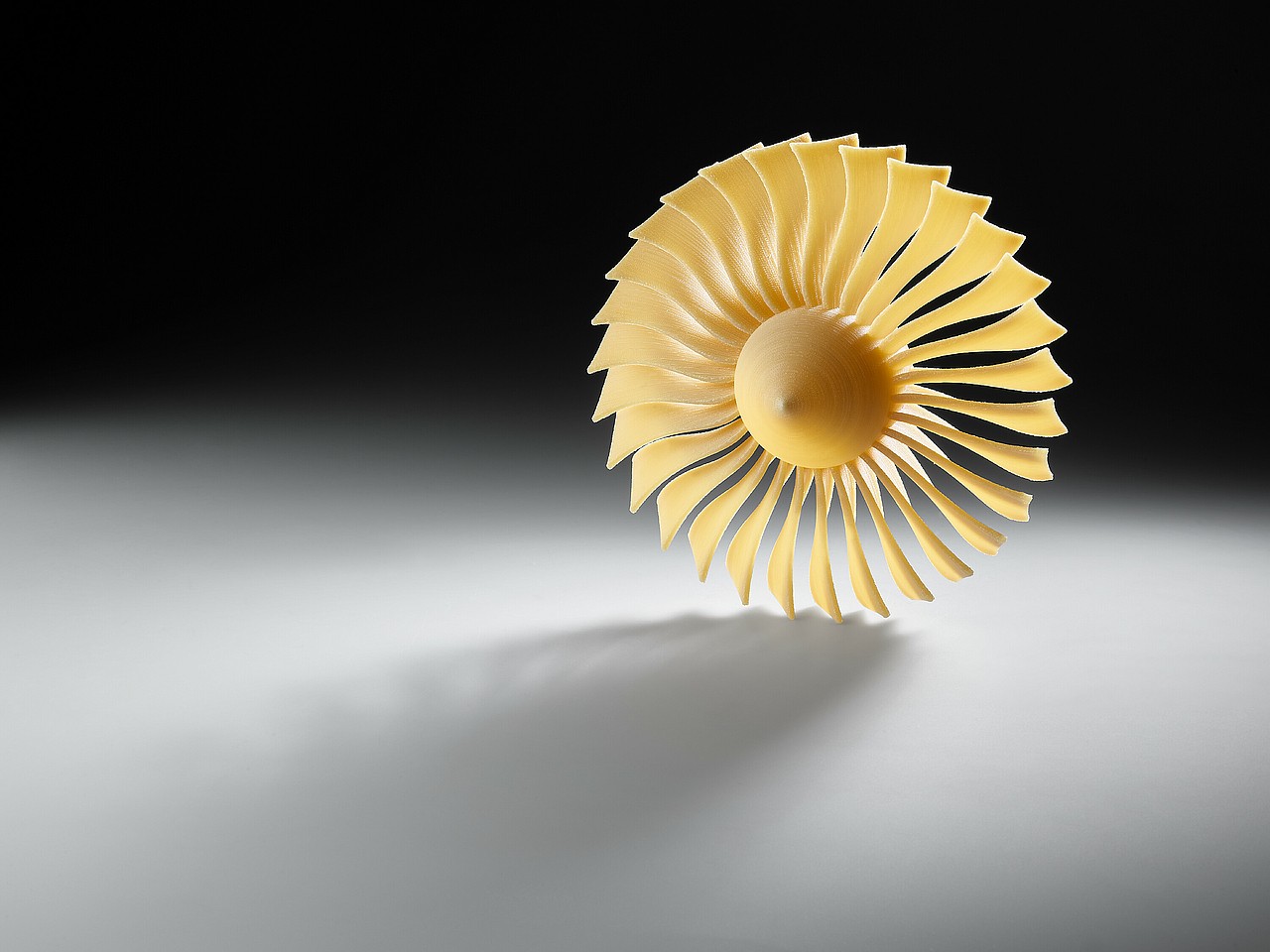

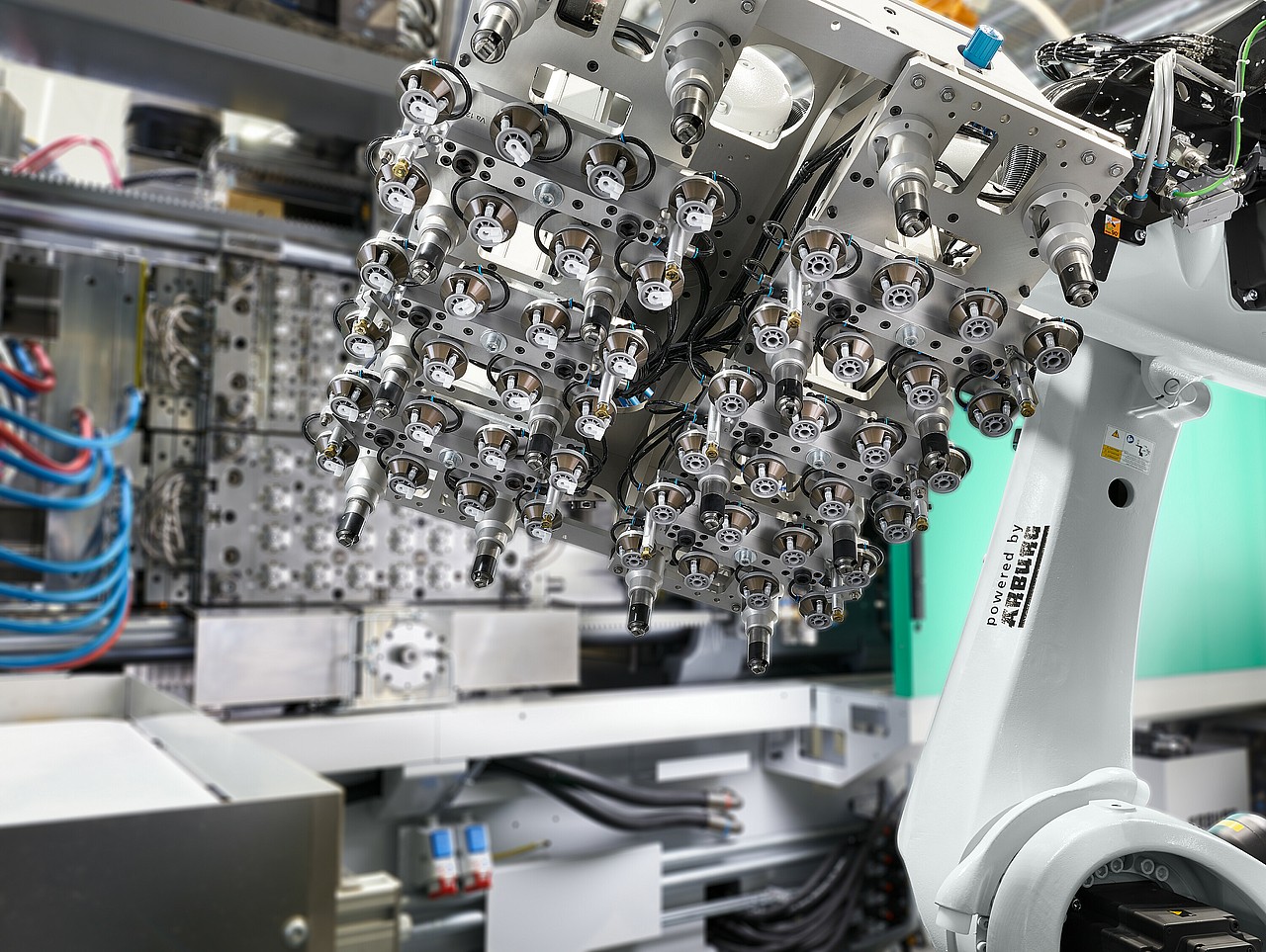

Micro counting wheel

They weigh just 0.004 g: a special micro production cell manufactures micro-counting wheels made of PBT. Nine pieces weigh as much as a single granule.

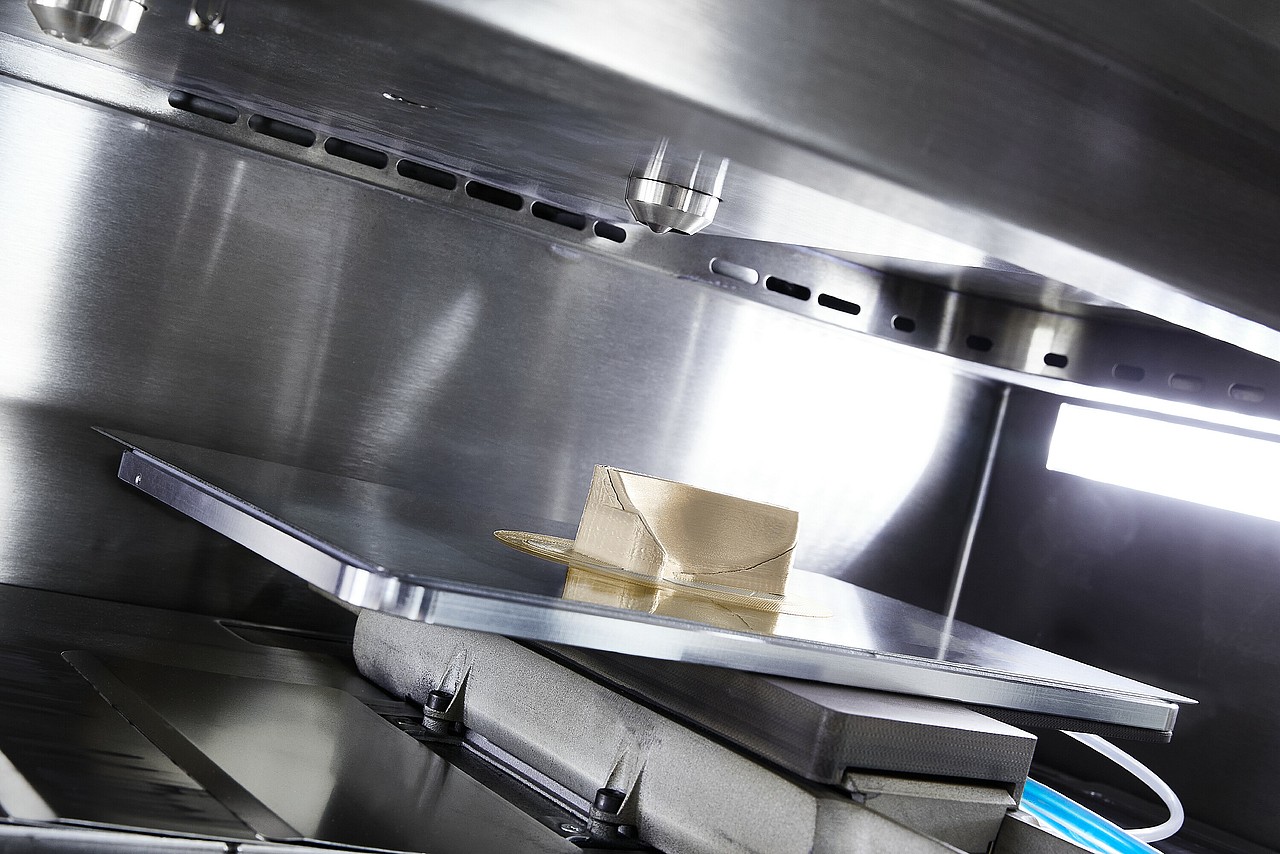

Spacer

A freeformer produces spacers for ALLROUNDERs from high-temperature plastic PEI. Injection moulding machine parts additively manufactured: You can do that too!

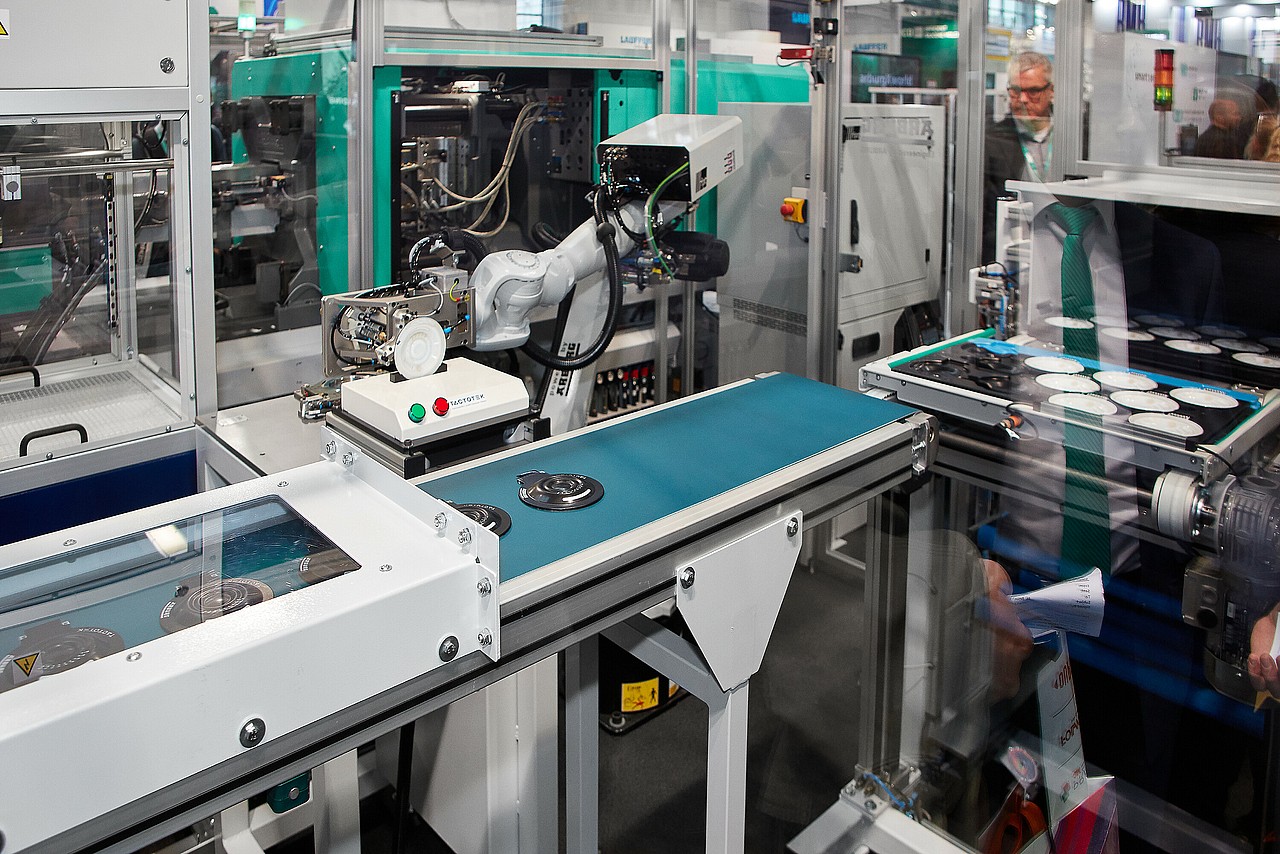

Lower basket rollers

Producing a ready-assembled lower basket roller for dishwashers 40 per cent faster: An ALLROUNDER CUBE with reverse cube system combines axes and rollers made of PP and POM.

This might also be of interest

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

With the freeformer, you can additively process the same plastic granules as with injection moulding. Use a wide range of certified original materials.

What do you need for your multi-component technology? Very flexible configurations. This is exactly what our modular ALLROUNDERs are designed for.