Energy-saving

High-quality machine technology and comprehensive process knowledge enable energy-saving operations and reliable, efficient plastics and recyclate processing. We can tackle this together!

Resource-efficient

For resource-efficient production and options for recycling plastic products, we can provide you with expert advice on topics such as production efficiency, carbon footprints and the use of recycled materials.

Central

Central production in Lossburg means a reduced carbon footprint – thanks to efficient logistics, a large vertical range of in-house production, environmentally friendly processes and the use of renewable energies, for example.

“For us, quality and reliability mean building machines and systems that are also sustainable. The use of high-end technology can help to conserve valuable resources and enable the circular economy.”

Samira Uharek, ARBURG Sustainability Manager

Sustainability examples

Made in Germany

Quality is the most important promise we make to our customers worldwide. This is why we produce our machines exclusively in Lossburg, Germany – in compliance with the highest environmental and energy standards. And have the complete drive train in house.

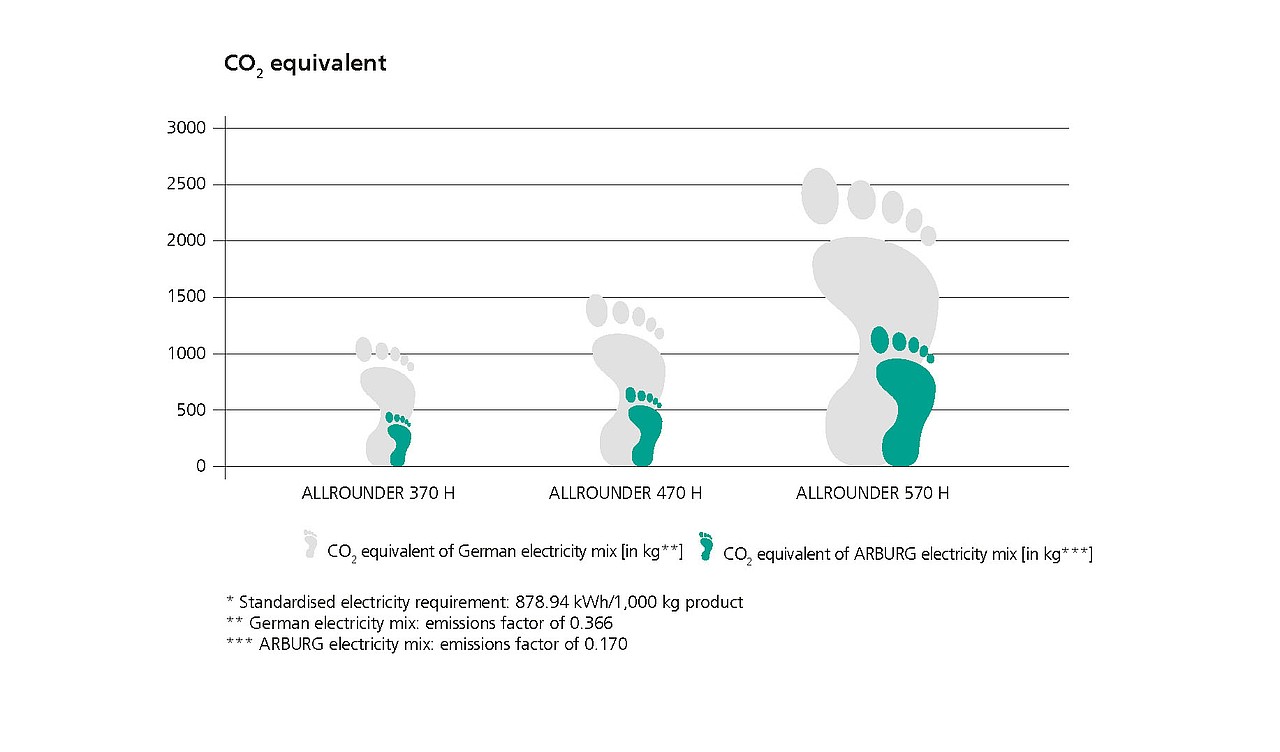

Carbon accounting

What is the carbon footprint of our ALLROUNDERs? We determine the product carbon footprint of the machines, including all raw material and electricity-related emissions. For an ALLROUNDER 570 H with a clamping force of 2,000 kN, for example, this is 16,430 kg of CO2.

To technical article (“Carbon footprint of injection moulding machines”)

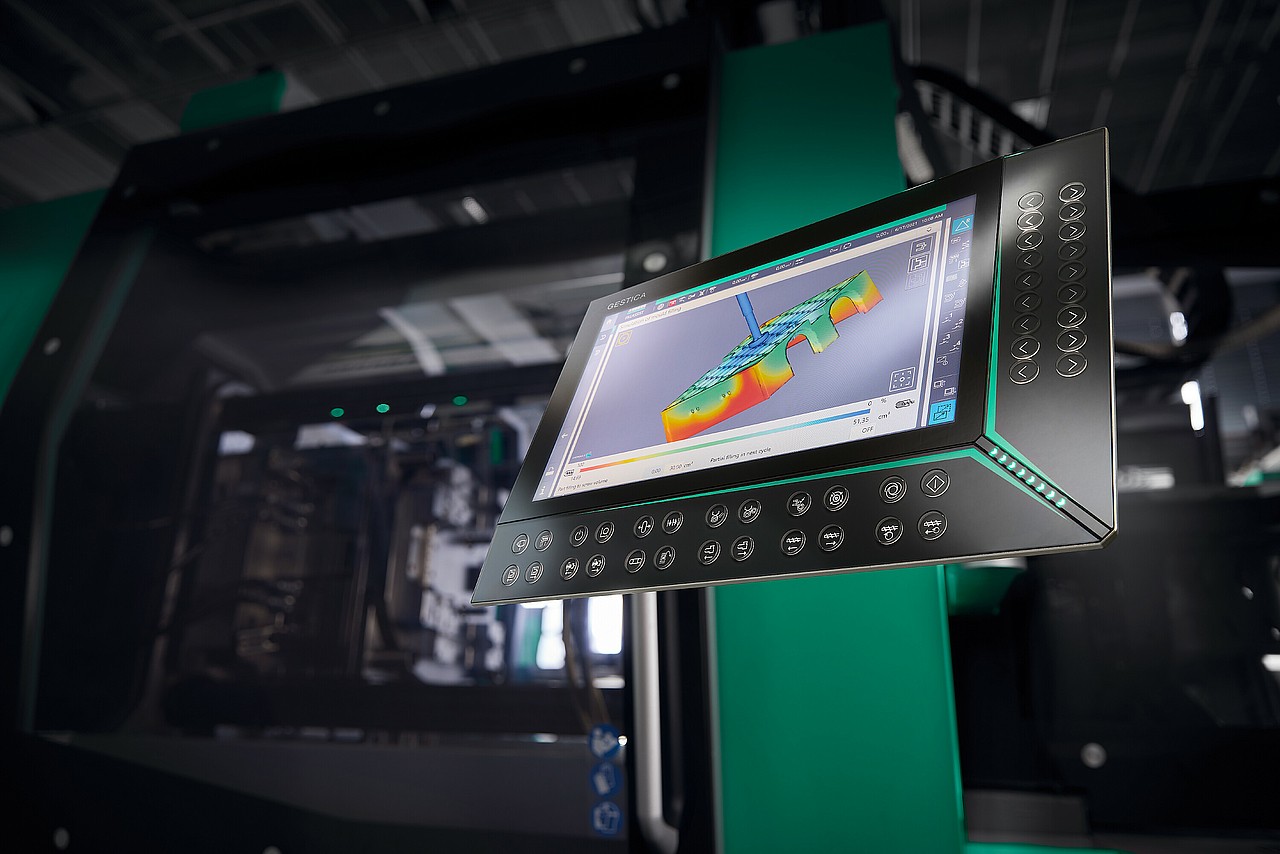

Innovative strength

Our innovative strength is your advantage. We have been pioneers in multi-component and powder injection moulding. The GESTICA controller sets standards in the industry. We are committed to sustainable plastics processing and hold several hundred patents!

This might also be of interest

Our “arburgGREENworld” programme brings together our activities in the areas of circular economy and resource conservation. With the aim of reducing carbon footprints and promoting the processing of recycled materials, for example.

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

We manufacture our machines for plastics processing exclusively at the ARBURG parent company in Lossburg, Germany. Learn more about our globally active family-owned company.