Benefits a glance

Brilliant

If you want to produce tiny injection moulded parts accurately and reliably, we've got you covered with our large range of injection screws from 8 mm, our micro injection unit 5 and the micro injection module.

First in, first out

Homogeneous melt preparation, short residence time, FIFO principle, this is the only way to get it right. Feel free to benefit from our high standards – and from our experience.

As standard

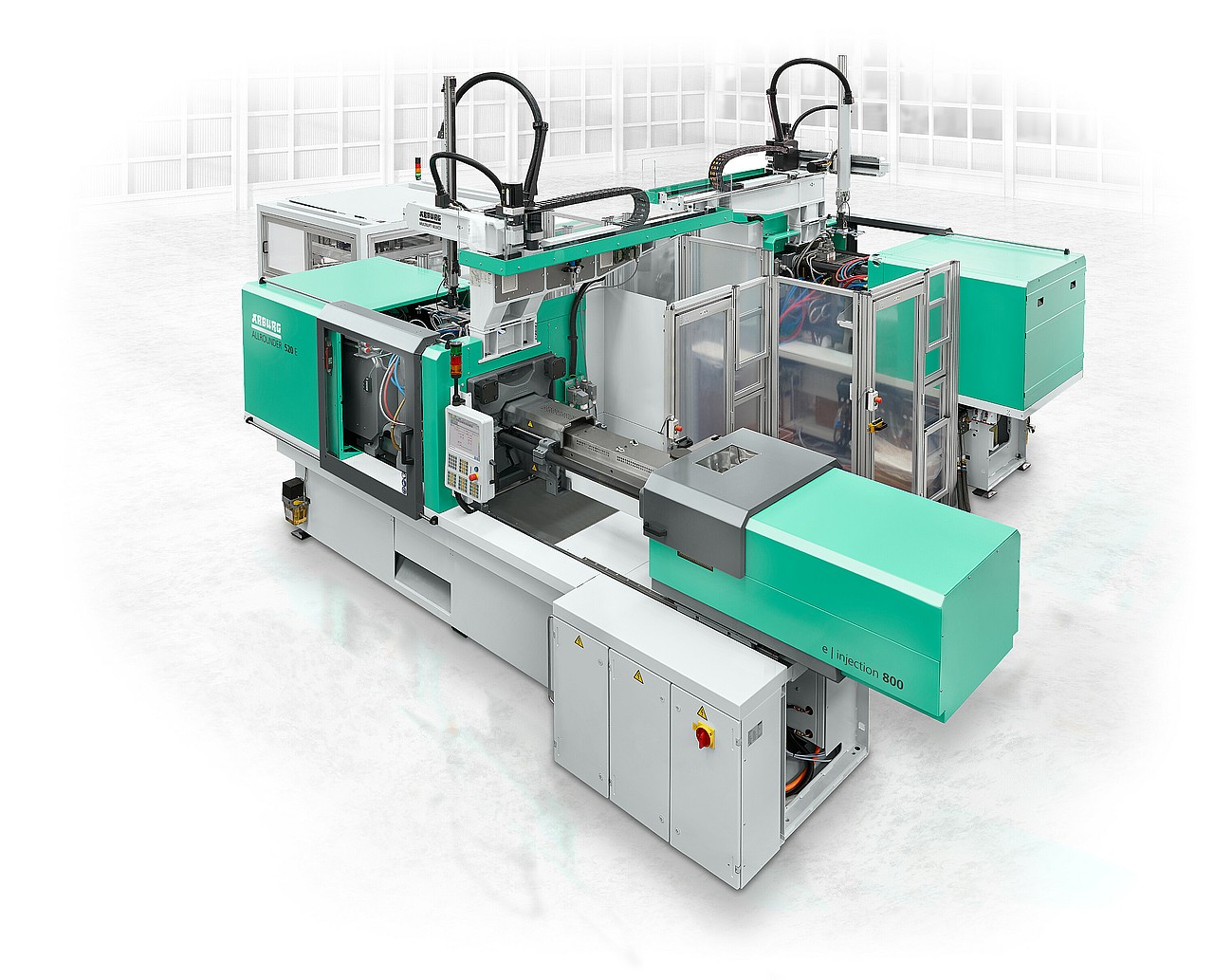

With our ALLROUNDERs, you can produce high-quality micro components in series without having to use expensive special-purpose injection moulding machines.

Modular

Thanks to our modular ALLROUNDERs, your production isn't limited to micro injection moulding. We can upgrade your standard machine to a turnkey solution.

Benefits of micro injection moulding

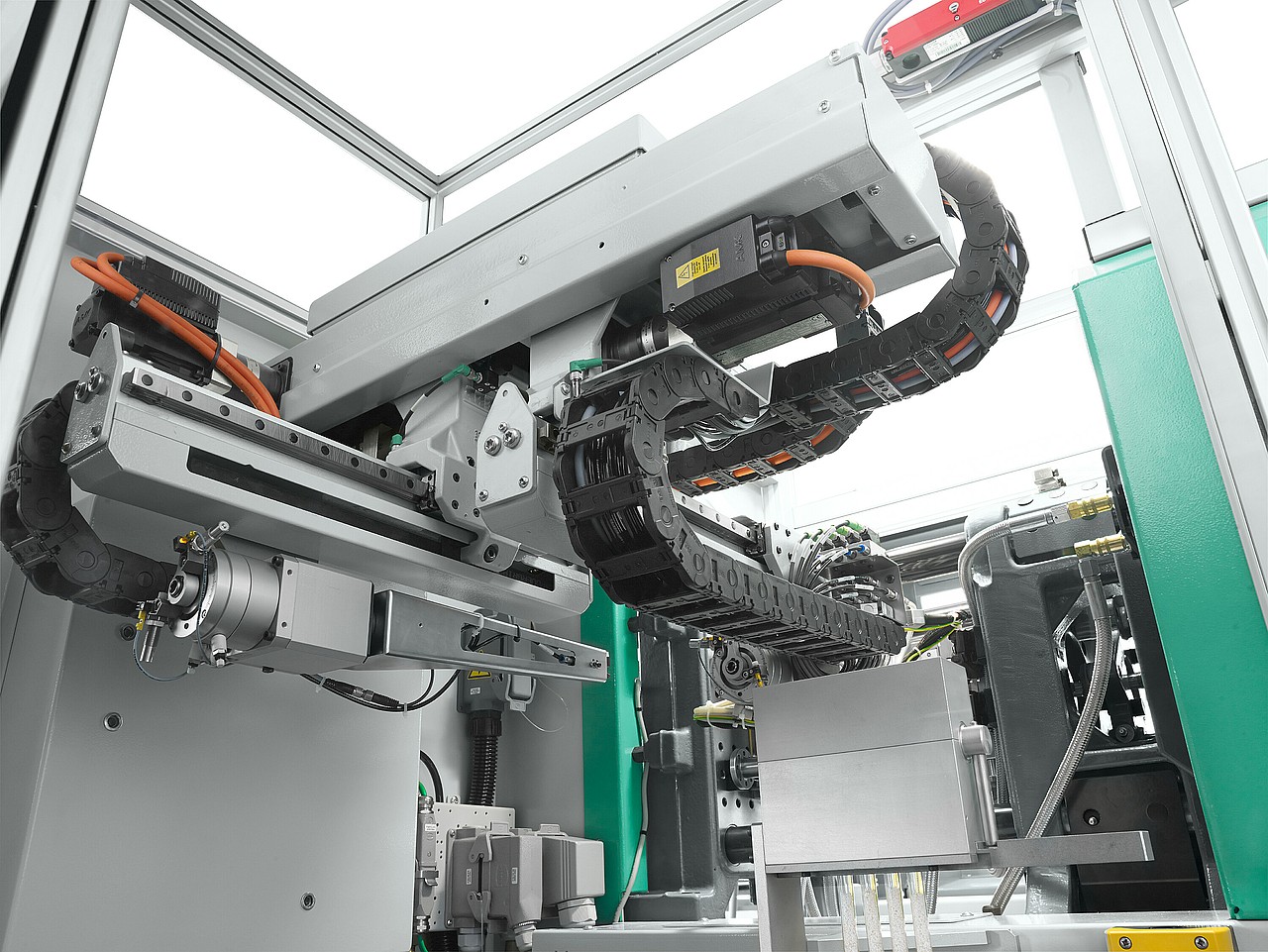

Optimised plastification

Optimised plastification

Consistent use of piston type injection units, FIFO principle, short residence times, material preparation for each shot new and homogeneous.

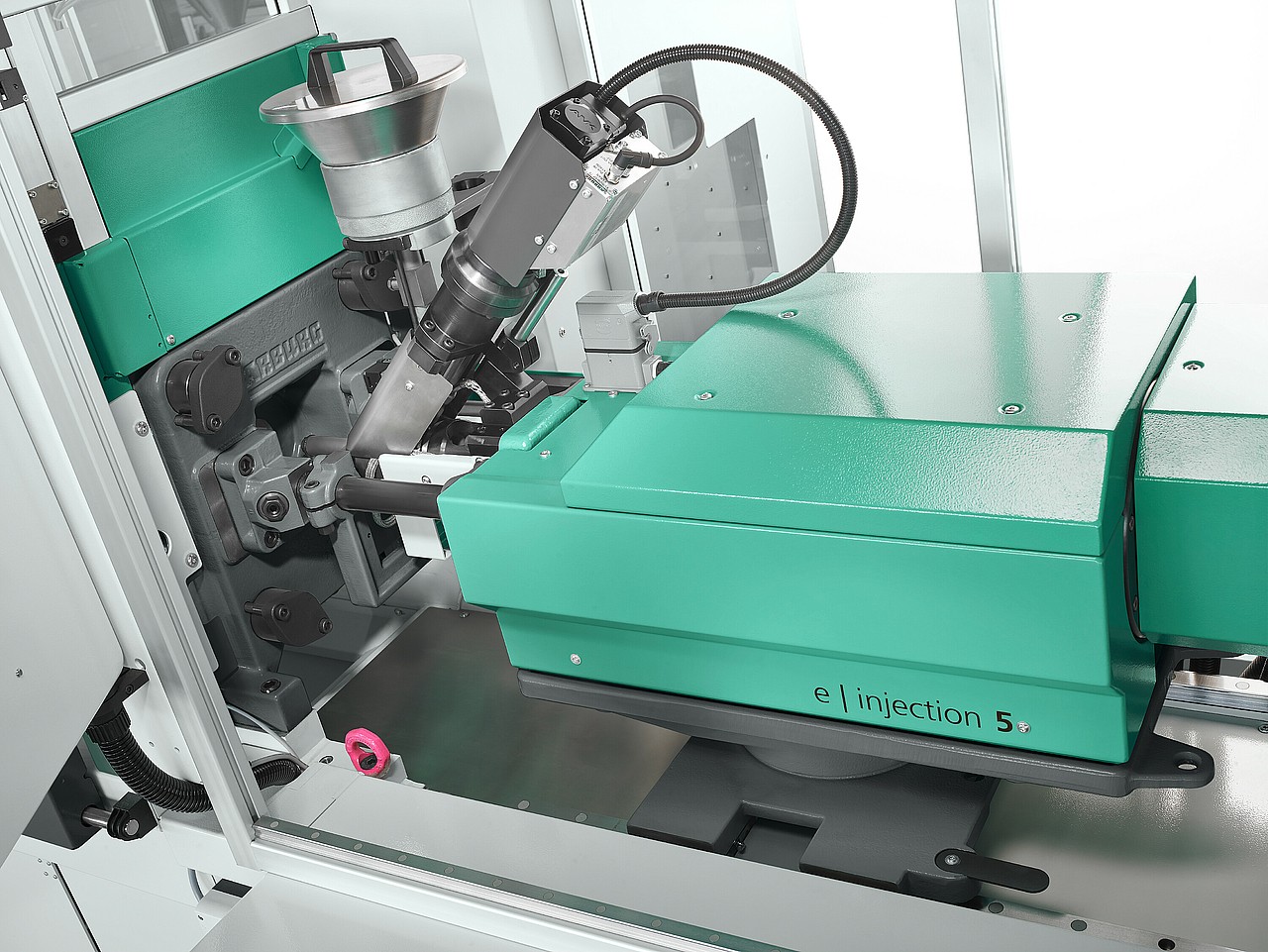

Micro injection unit

Micro injection unit

Special micro injection unit, also for processing tiny parts made of liquid silicone (LSR), optionally with LSR cartridge.

aXw Control ScrewPilot

aXw Control ScrewPilot

Micro injection moulding process precisely controllable, for all common plastics, control with "smart" assistance functions, aXw Control ScrewPilot for regulated injection.

Clean-room module

Clean-room module

ALLROUNDER can be expanded into a system solution for micro components, with clean room modules, ionisation and automation.

Part examples

Micro counting wheel

They are only 0.004 g in weight: a special micro production cell manufactures four micro counting wheels made of PBT in a cycle time of 12 s each. Nine pieces weigh as much as a single granule.

Cap

At the heart of a micro-turbine for flow meters is a magnet. During production, the magnets are first separated, aligned, placed in a mould and overmoulded with PVDF.

Micro turbine

At the heart of a micro-turbine for flow meters is a magnet. During production, the magnets are first separated, aligned, placed in a mould and overmoulded with PVDF.

Automated production cells

Increase added value, optimise the injection moulding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As is already the case for many leading companies worldwide.

This might also be of interest

Producing parts with high precision and in accordance with the most stringent functional and quality criteria – this is what our electric ALLROUNDER ALLDRIVE machines are designed to achieve.

Take advantage of our expertise – from moulded part design to mould and machine configuration. And application technology, for example in our Customer Center.

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.