Benefits at a glance

Intuitive

Easy-to-understand user interfaces on our machines and automated slicing software make working with our entire AM program simple and reliable.

Limitless

The choice of materials is limitless: certified original materials, combinations of materials and colours, resilient hard/soft combinations, soluble support materials – everything is possible!

Emission-free

All our machines operate with zero emissions or residues. The freeformer is suitable for clean room applications. Water-soluble support material saves manual finishing work.

Easy to understand

Our experts at ARBURG and innovatiQ are the best people to answer your questions. Plus: support from a professional and dense service network.

ARBURG Plastic Freeforming with freeformers

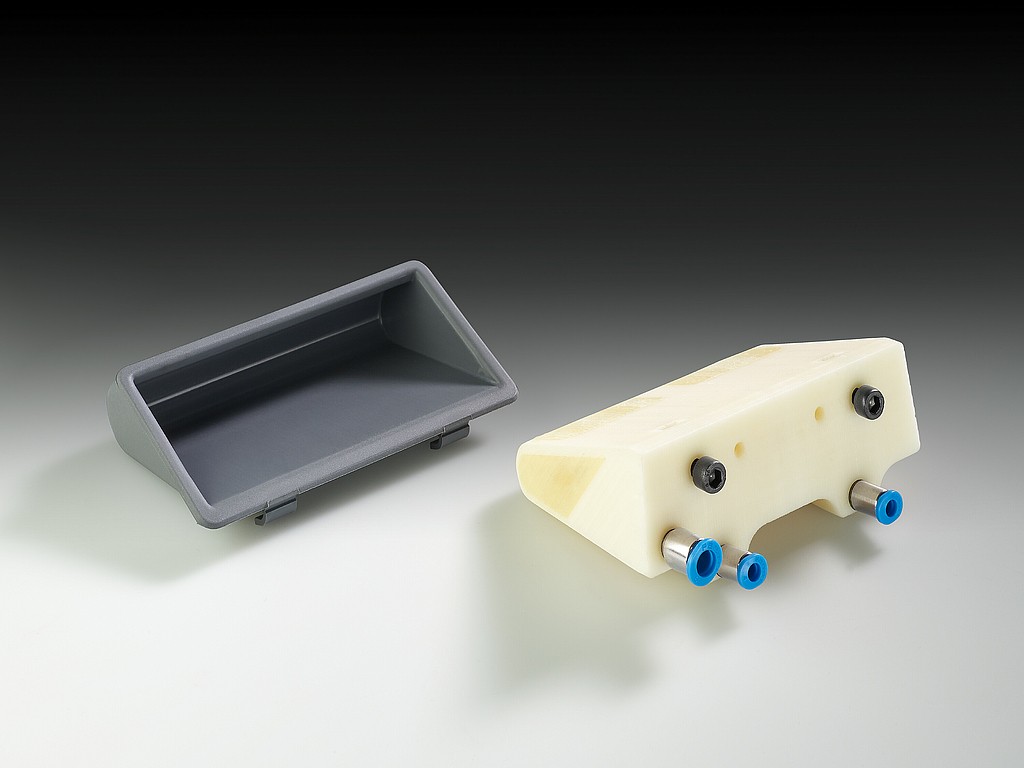

Sample components

Implants

Resomer LR 706, for example, is used to make resorbable implants that can be inserted directly into the body after bone fractures.

S-pipe

Thick-walled S-pipes can be additively manufactured without distortion. With the aid of support materials, cleverly inserted and later dissolved in a water bath with no finishing work.

This might also be of interest

Create added value through integrated functions and customised design. For the industrial additive manufacturing of resilient plastic parts from original material.

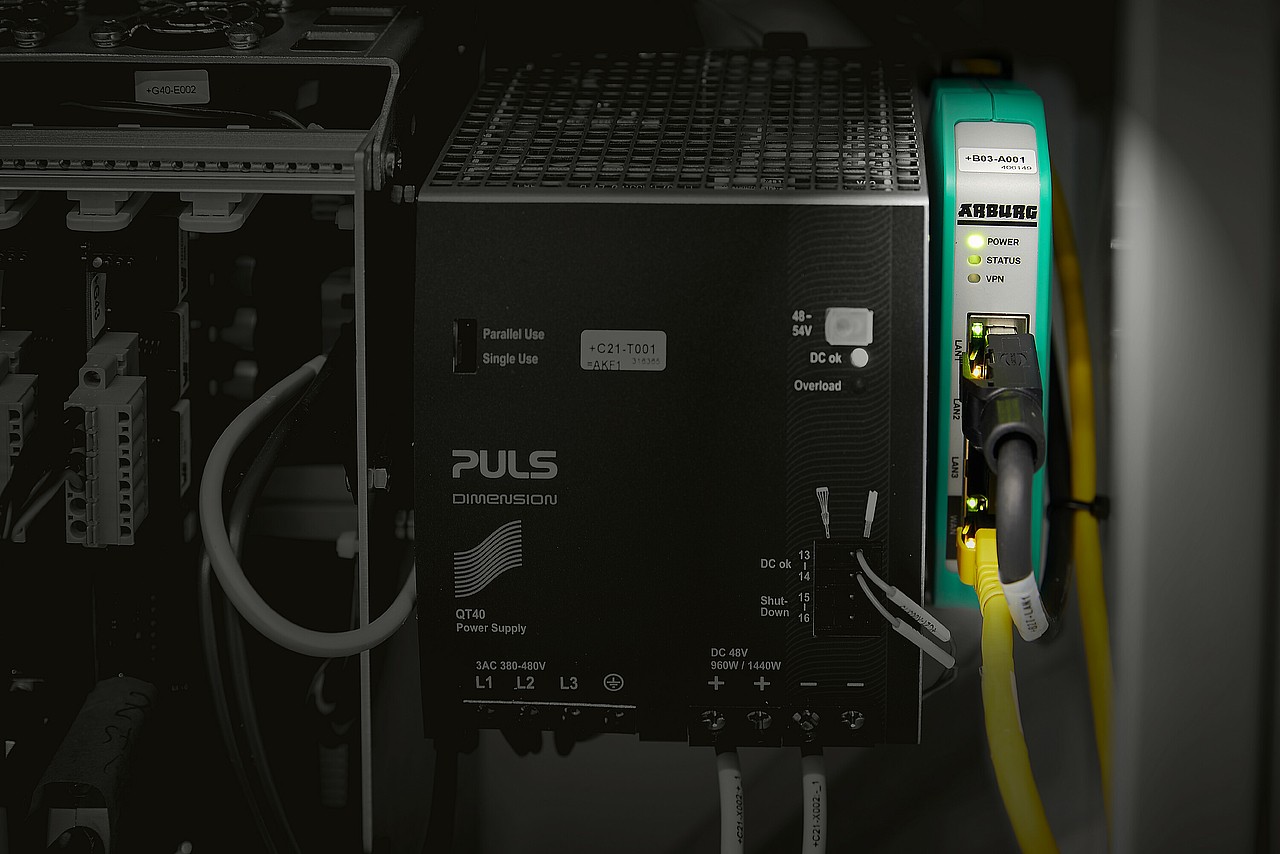

Increase your production efficiency. With the digital arburgXworld customer portal. Our apps and assistants make it easy for you.

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.