Benefits at a glance

Synchronised

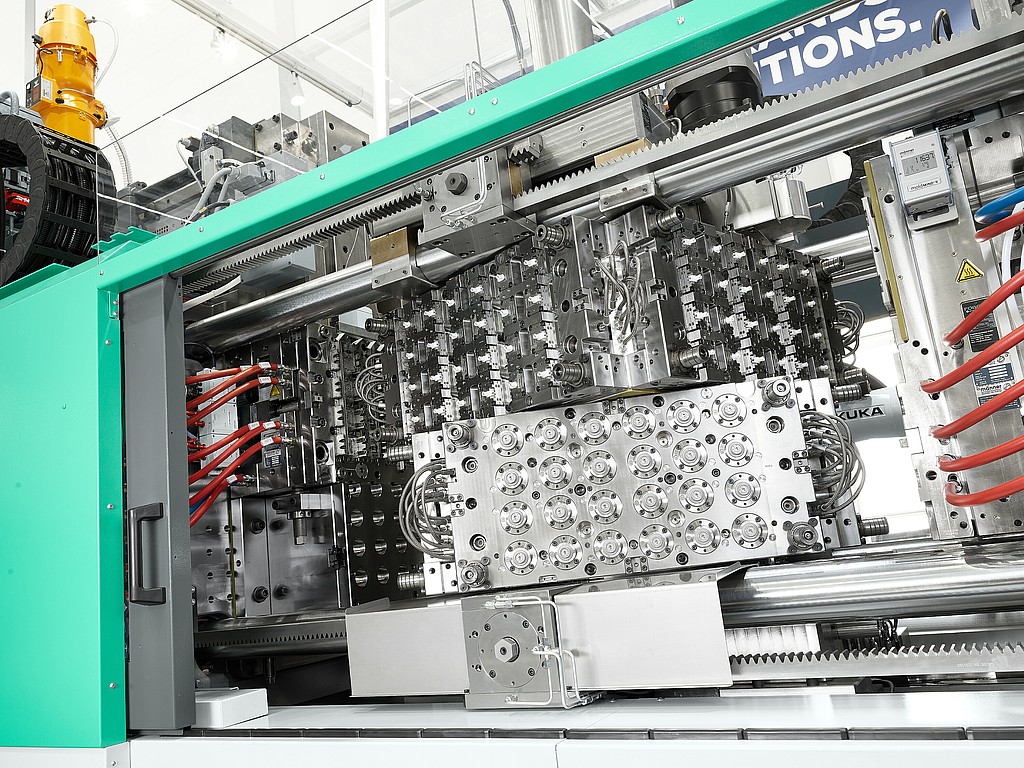

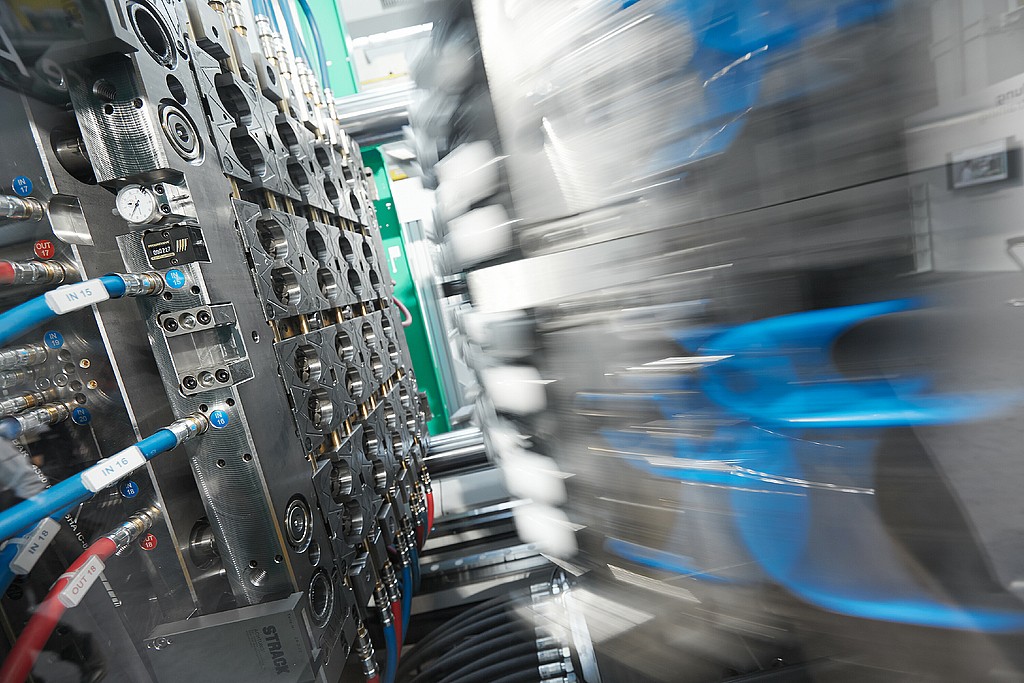

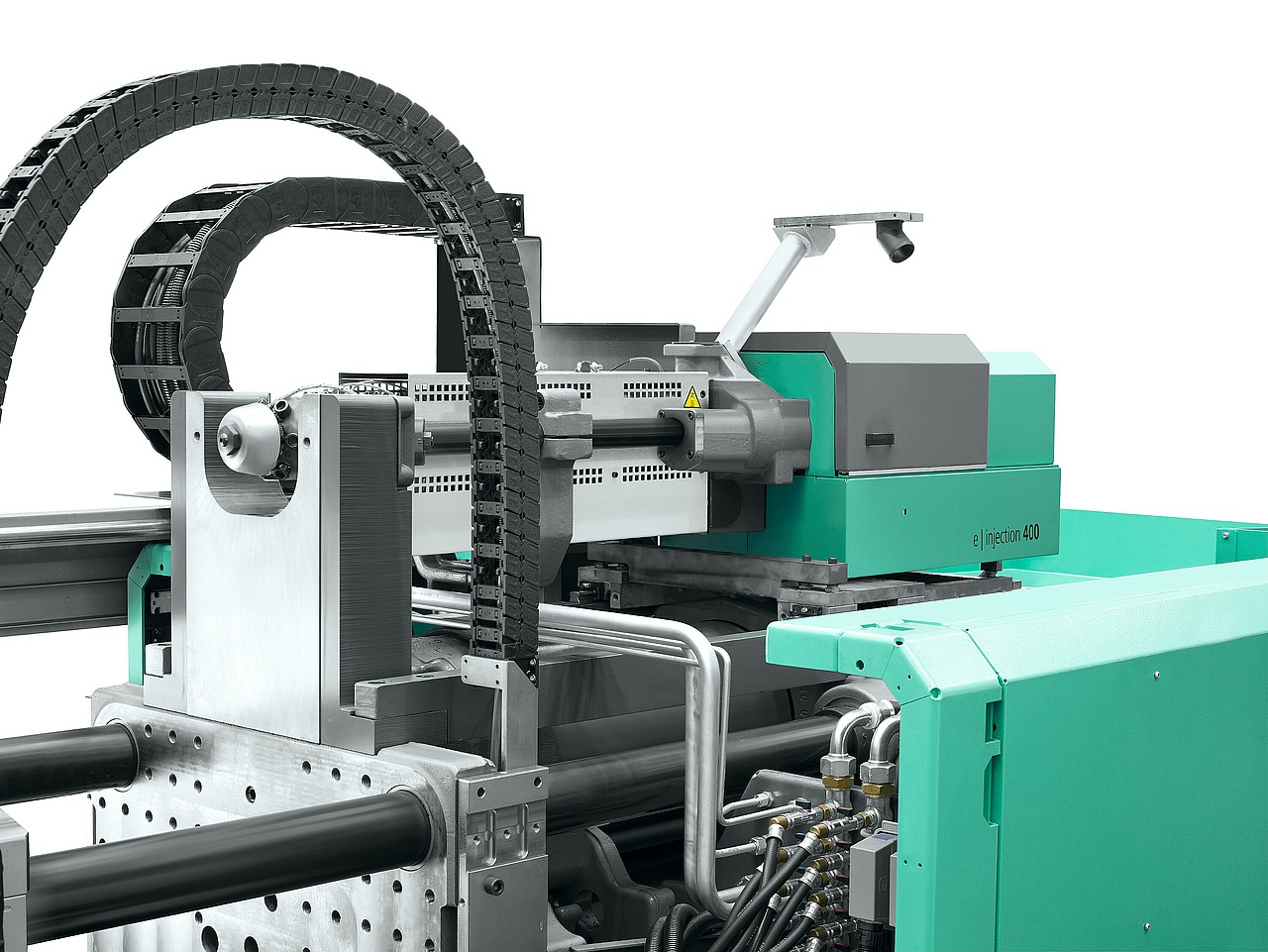

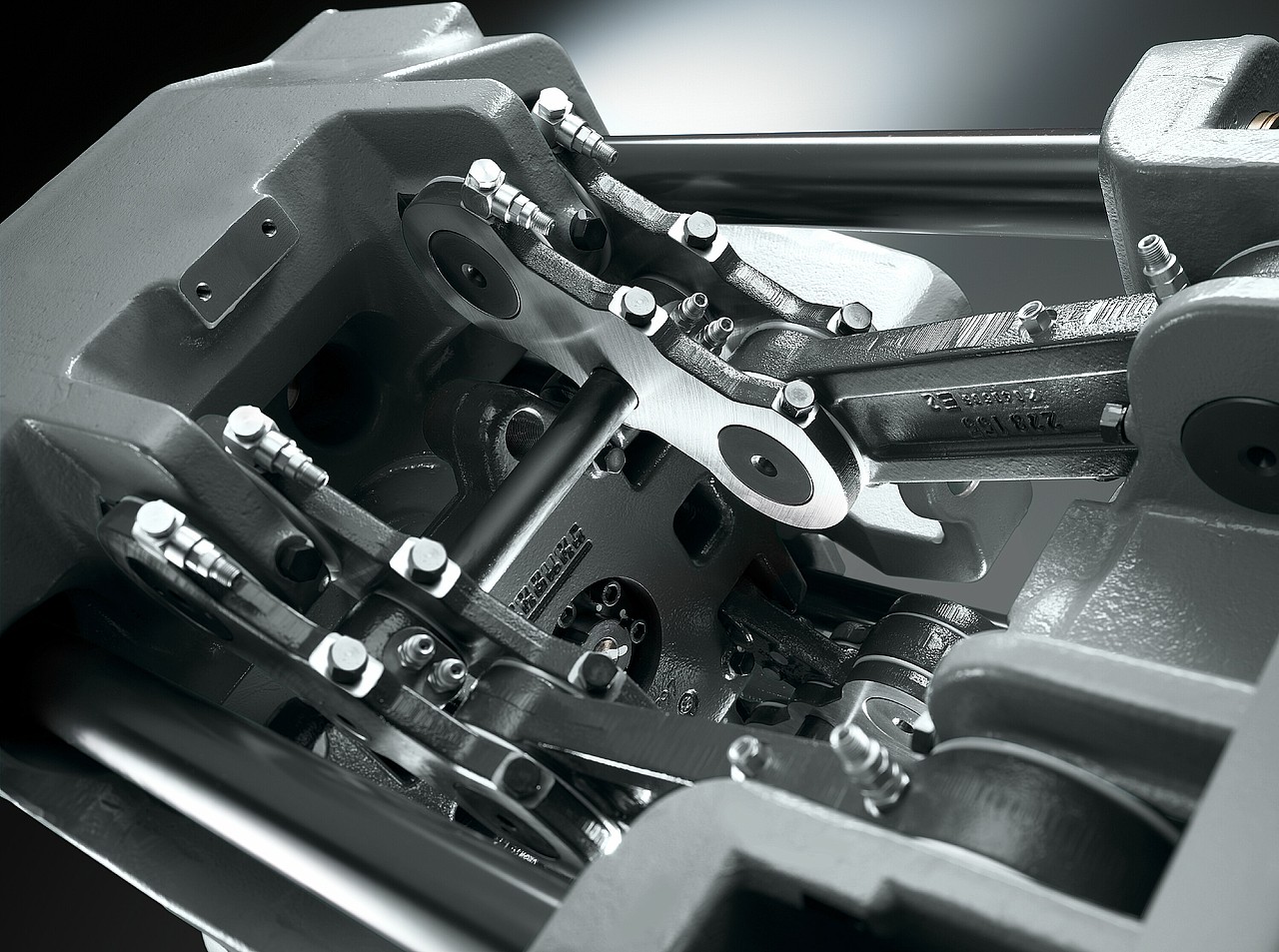

Our ALLROUNDER CUBE machines are specifically adapted to cube moulds. Use synchronised machine technology for simultaneous mould filling, cooling and removal.

Space-saving

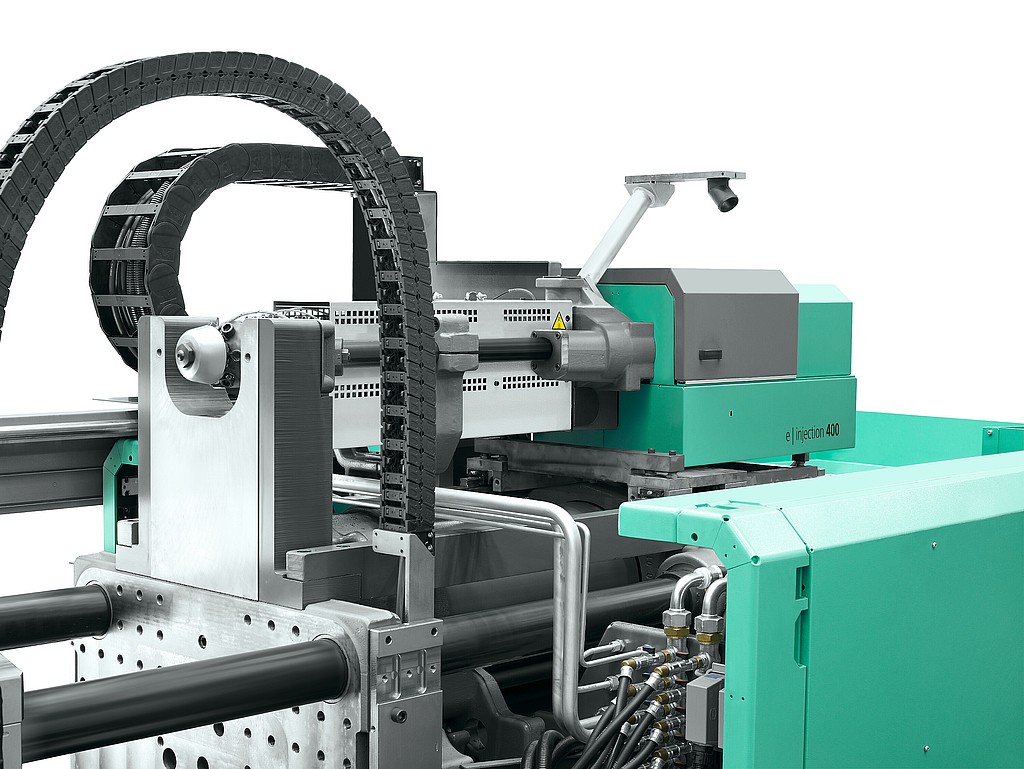

The principle of success? High output on a small footprint. With a second injection unit above the moving mould mounting platen. And a particularly compact cube system in the form of the CUBE 1800.

Double

Cube-mould technology is particularly interesting when you reach a productivity limit with your standard machines. You can double your output with just one CUBE machine.

Integrated

Want to integrate process steps without sacrificing output quantity? With the ALLROUNDER CUBE, unscrewing, removal and assembly, for example, take place with no effect on cycle time.

Technical data

Part examples

Lower basket rollers

Producing a fully assembled lower basket roller for dishwashers 40 per cent faster: an ALLROUNDER CUBE with reverse cube system from Foboha increases part quality and cycle time.

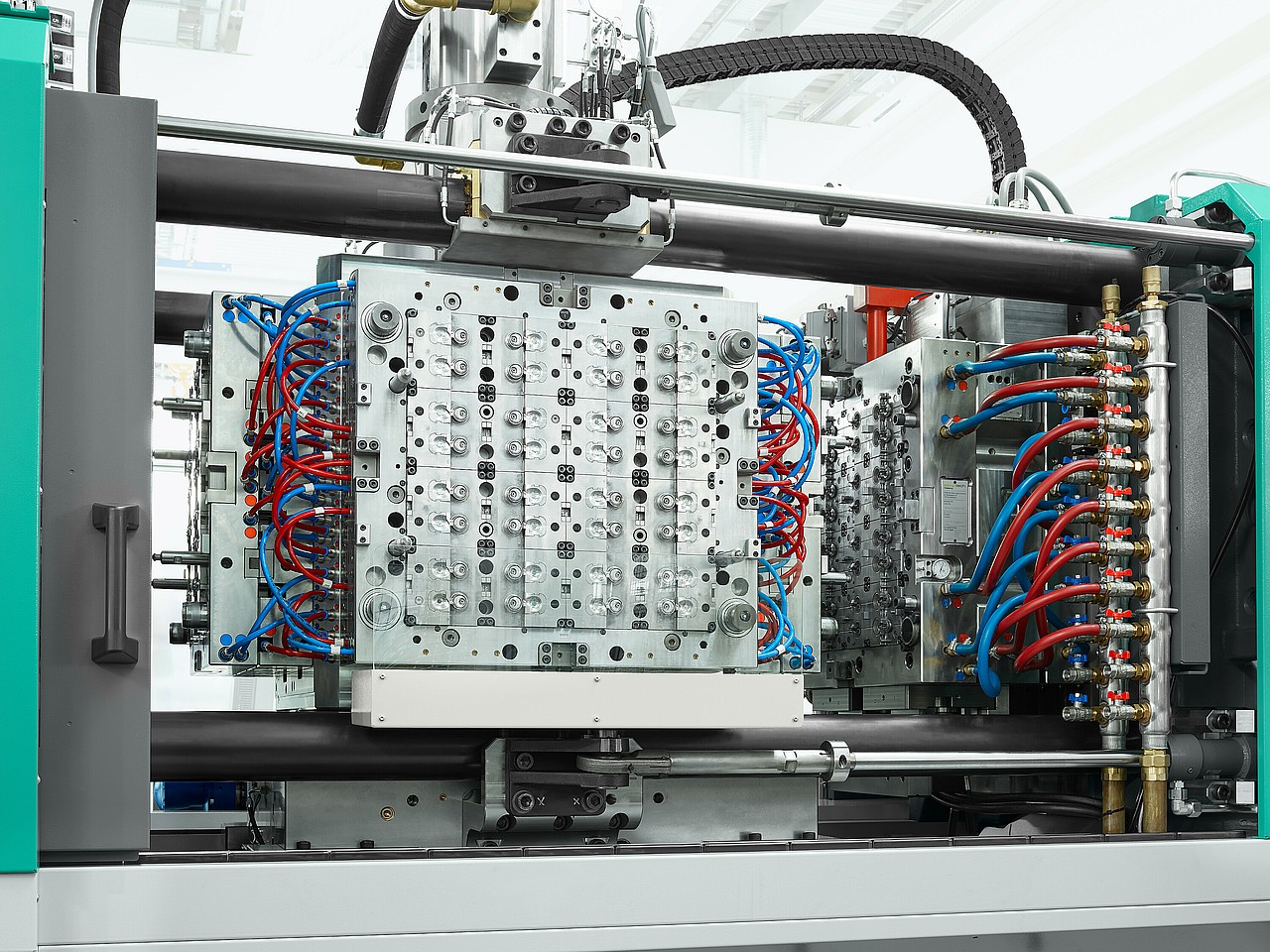

3-component functional part

Using an 8+8+8-cavity mould from Foboha, an ALLROUNDER CUBE 1800 produces a functional component from PP, TPE and POM in assembly injection moulding.

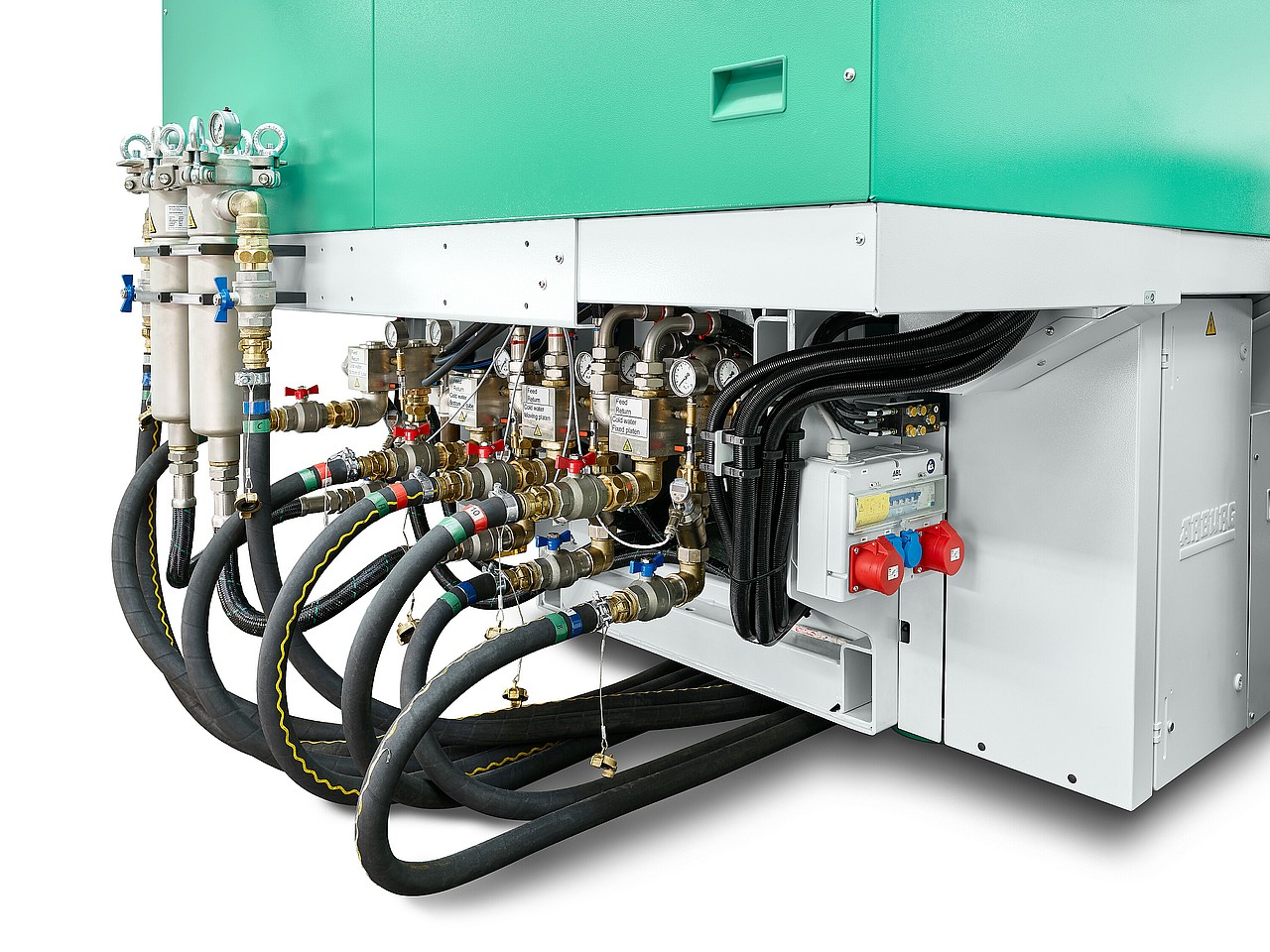

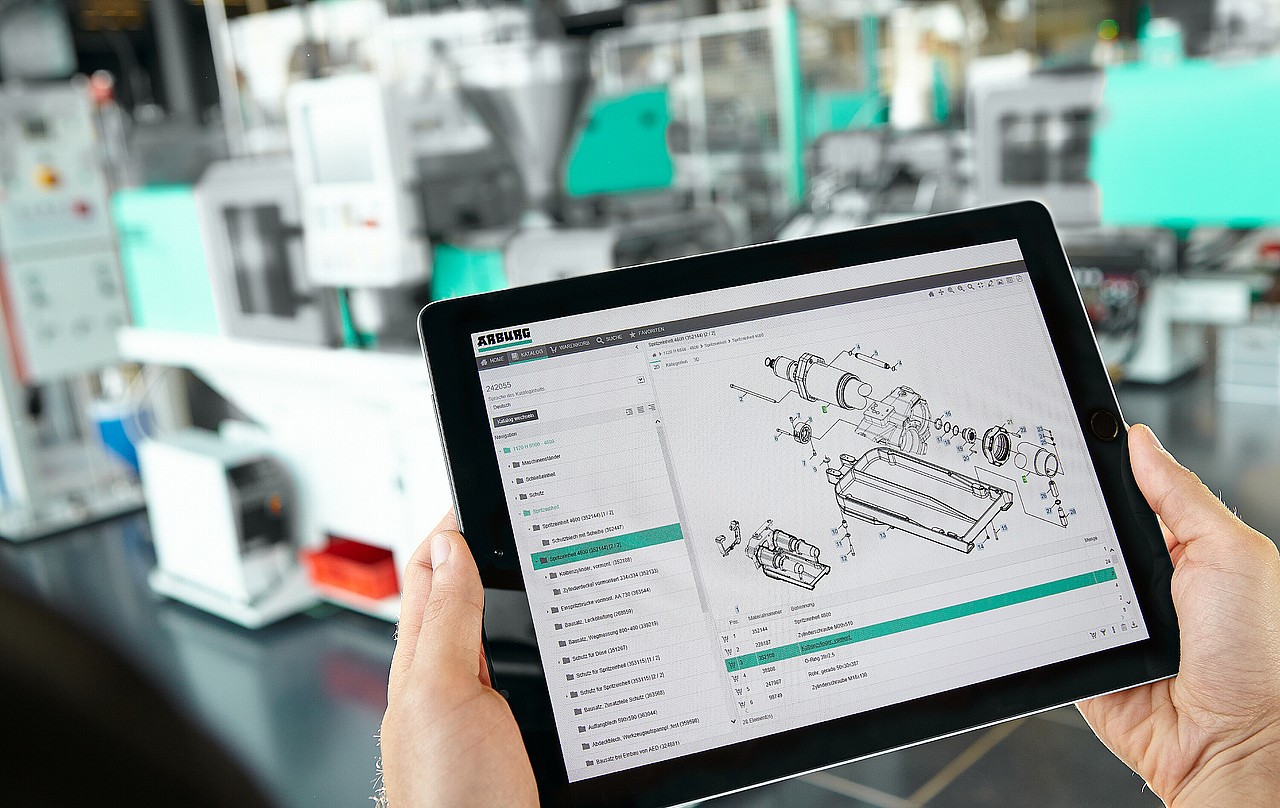

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also interest you

Thin-walled parts, IML products, screw caps? Our packaging machines combine FEM-optimised mould mounting platens, precise mould movements, high filling dynamics, short injection times and high plasticising flow rates.

Want to increase added value, optimise the injection moulding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.