Innovative

Together with BASF, ARBURG produced segregation-free, thin-walled PIM housings for smartphones for the first time worldwide in 2016.

Cost-effective

Metal injection moulding (MIM) offers a low-material alternative to the conventional machining of stainless steel, titanium or zirconium oxide.

High-quality

The mould with liquid-tempered hot runner produces very good surfaces that can be highly polished.

ARBURG solutions used

ALLROUNDER 470 S

A hydraulic ALLROUNDER 470 S with PIM equipment produces a green compact of a smartphone back in around 60 s cycle time. Frames can be produced alternatively with an interchangeable mould.

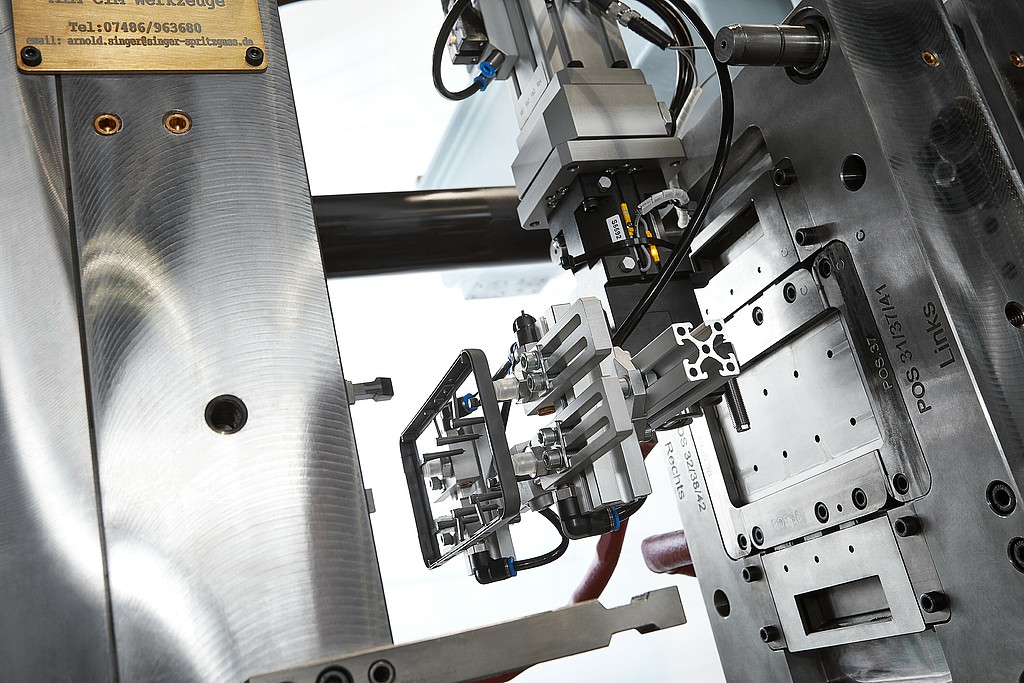

MULTILIFT SELECT

A MULTILIFT SELECT linear robotic system gently removes the parts and places them on a slide rail. The green compacts are then debound and sintered.

ARBURG PIM laboratory

In ARBURG's own PIM laboratory in Lossburg, customers can test all the important process steps – from feedstock and injection moulding to binding and sintering the moulded parts.