Benefits at a glance

Comprehensive carefree

Comprehensive carefree package: Only one contact person for project planning, implementation, installation and service, including CE certification.

Around the world

We can provide turnkey solutions anywhere. Specially trained turnkey experts are available in Germany and in international subsidiaries.

Around the clock

So that you can be sure right from the start: Every turnkey system is tested and optimised by us before delivery. Use it for efficient 24/7 production!

In partnership throughout

Proven partners, interdisciplinary team. Each concept is discussed and evaluated. Make the most of your technology and system partner ARBURG.

Added value with turnkey systems

Sample parts

Cable grommet

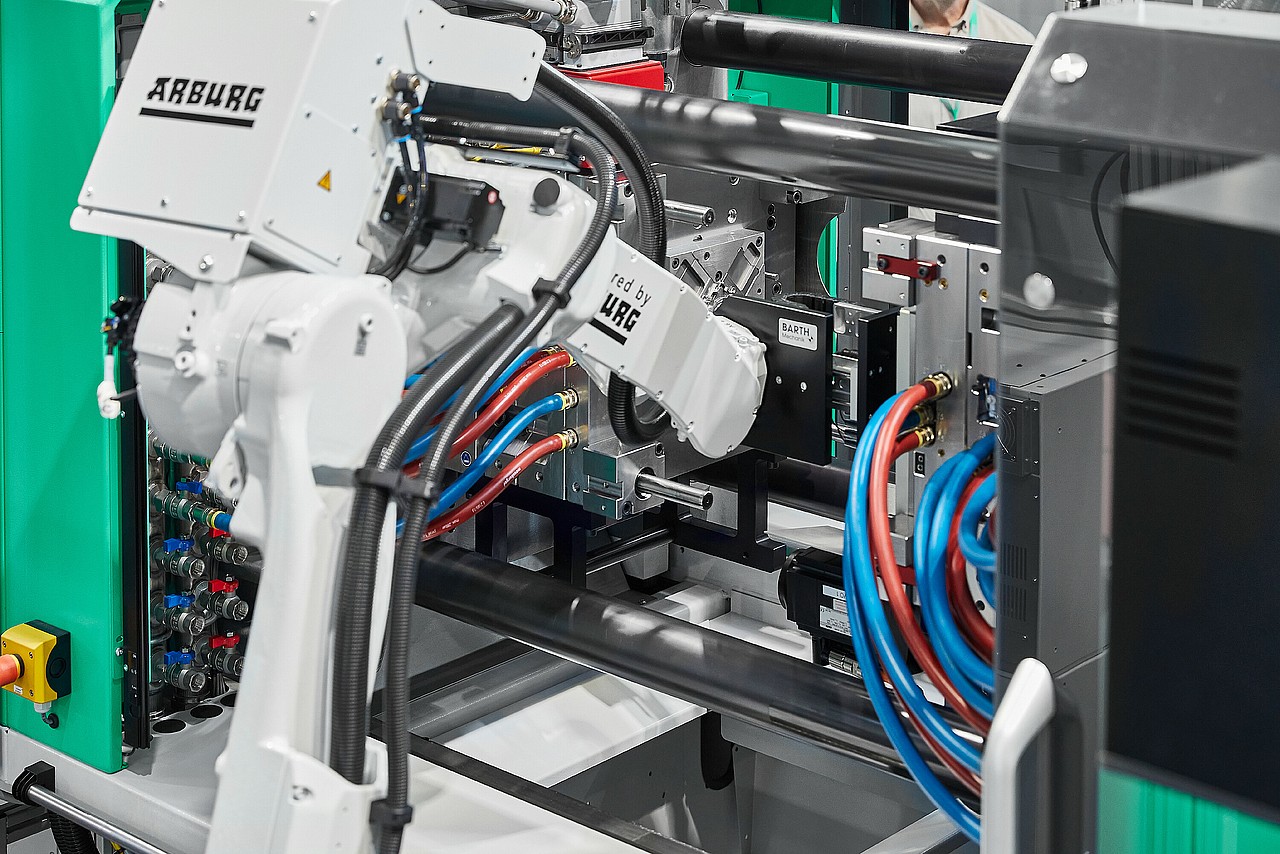

Flexible parts such as cables are individually prefabricated and inserted into the mould cavities with a six-axis robot. The length of the cable loops can be set flexibly.

Night light

The night light example shows how multi-functional component surfaces can be produced using film insert moulding (FIM). The process is ideal for high-quality touch functions for digitalisation, for example in car interiors.

icam connector

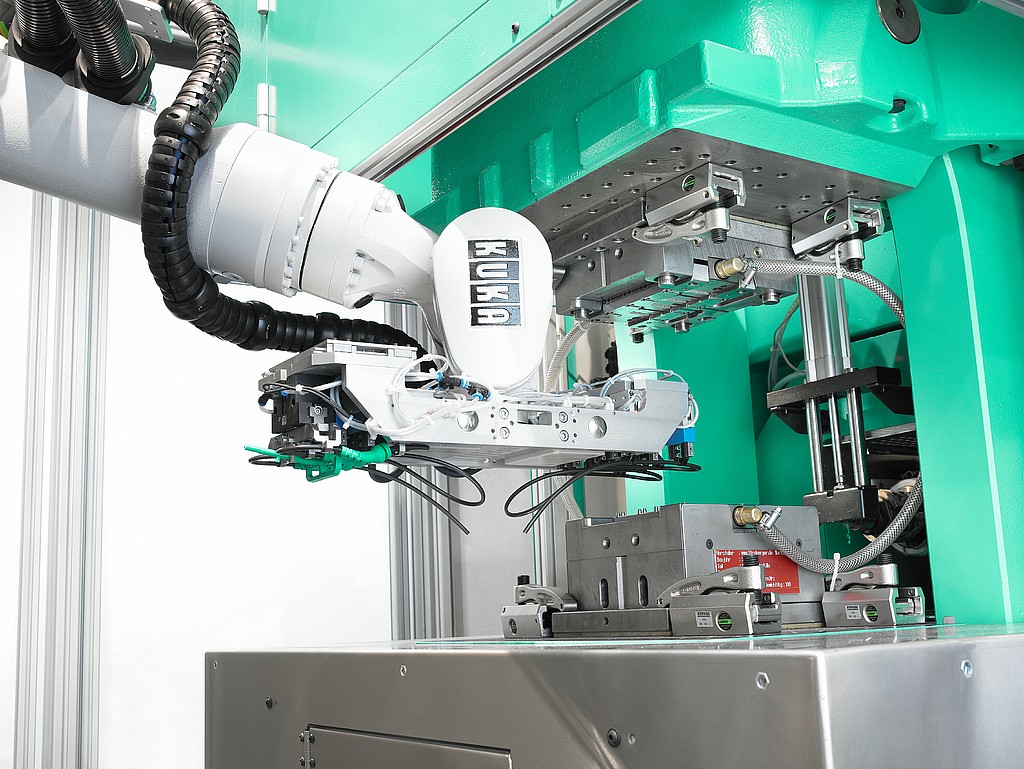

Digital cameras (icams) assist with parking. The secure connection between the camera and the electronics is ensured by eight-pin connectors manufactured in a fully-automated process on a rotary table machine – two million units per year.

This might also be of interest

Digitalise your injection moulding production to suit your individual needs. We have the tools! From machine, process, automation and controller technology to IT cross-linking.

From sprue removal to complex handling: our robotic systems are ready for your tasks – with little set-up effort and short set-up times.

Make use of synergies for your injection moulding operation with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.