Benefits at a glance

Economical

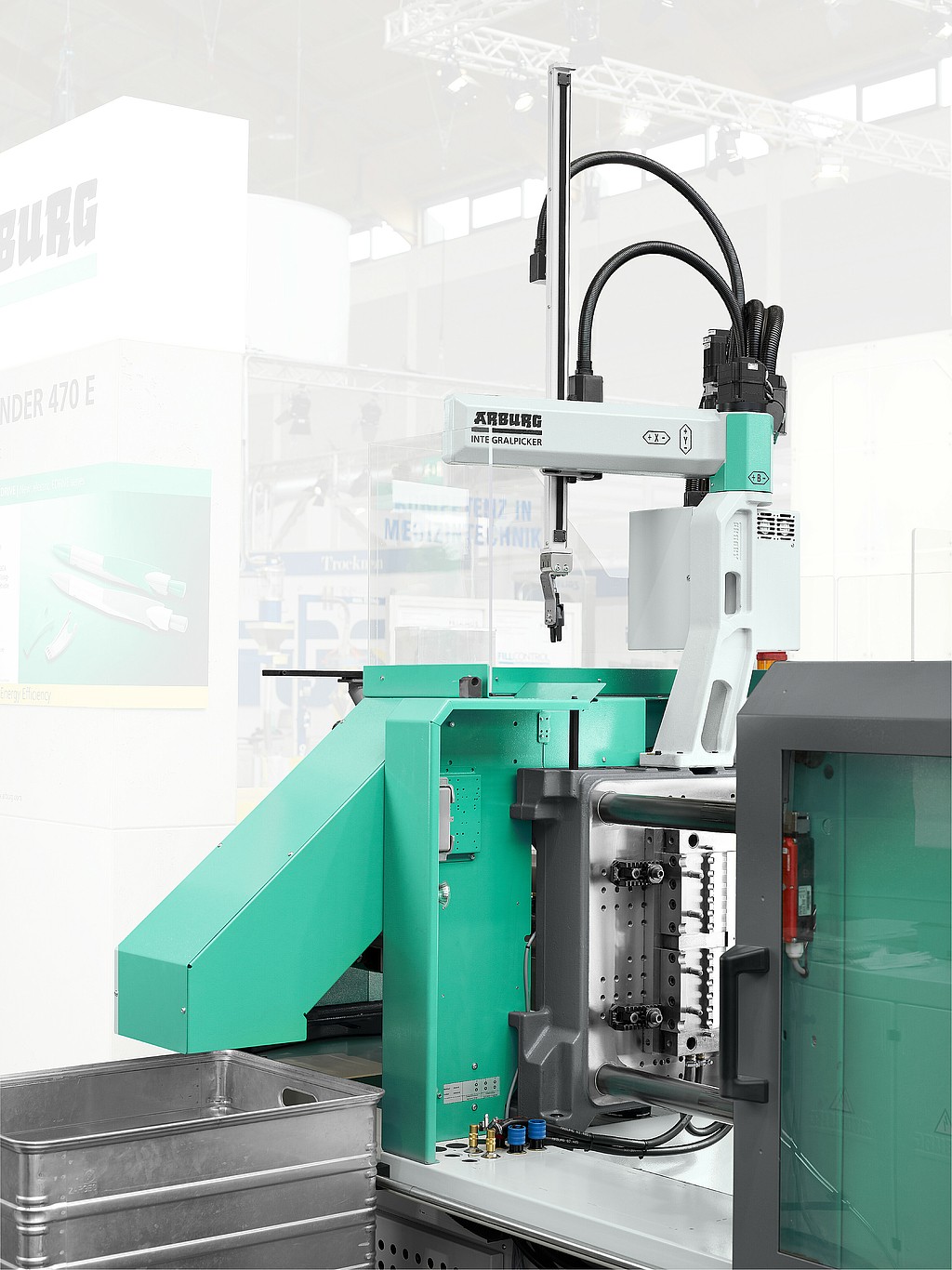

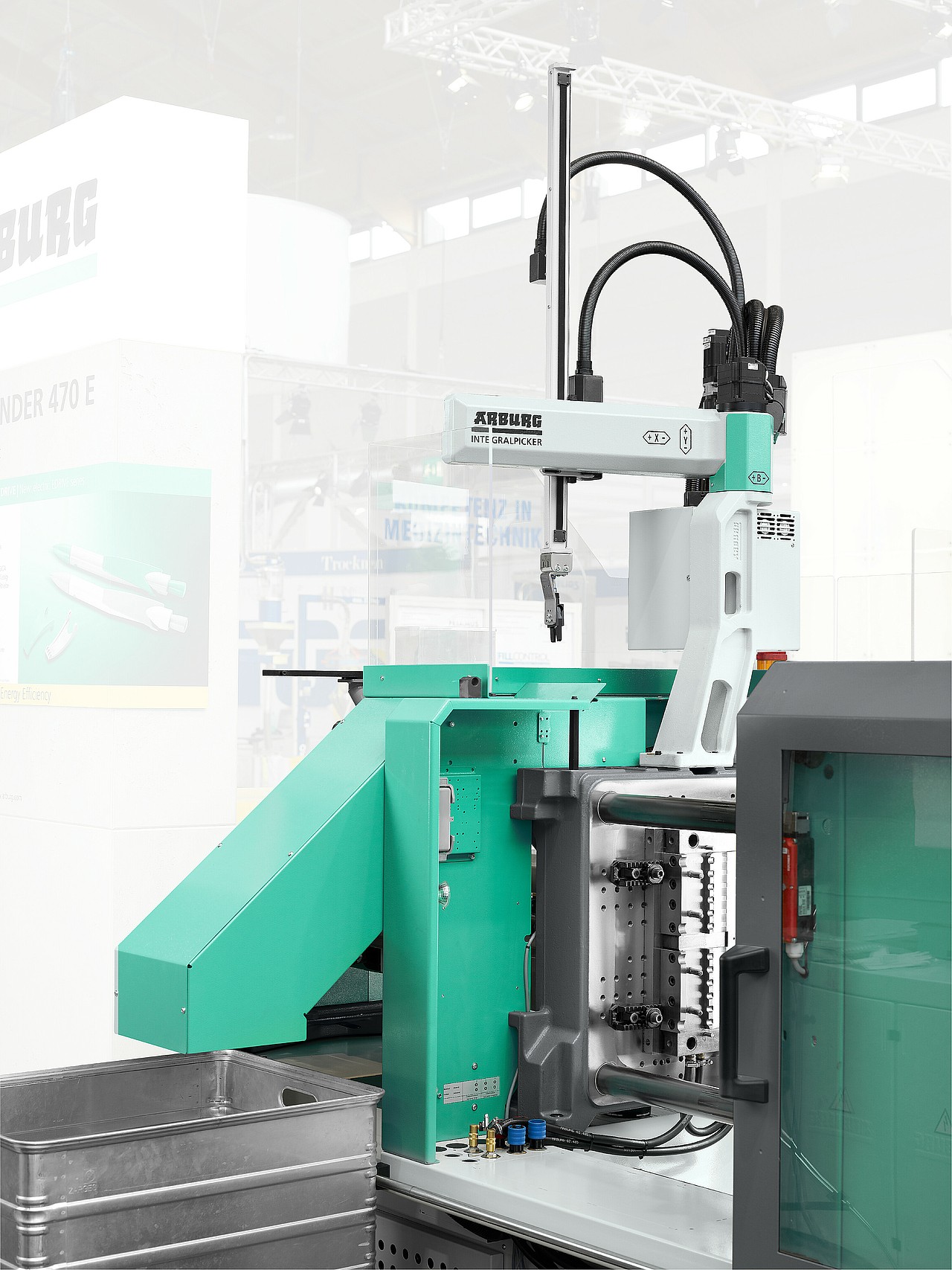

Simple, fast and reliable: our INTEGRALPICKER V – for efficient and compact parts handling. Making your move into automation a success.

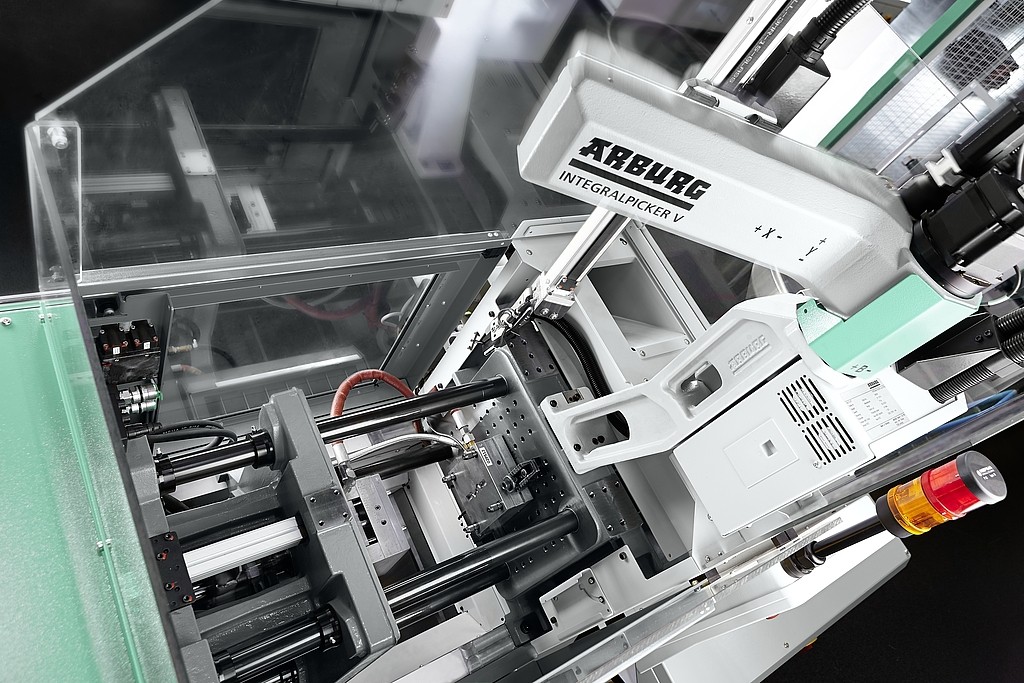

Servo-electric

The ARBURG picker is really quick! And works precisely with three servo-electric axes. For sprue removal, the robotic system enters the mould vertically.

Freely programmable

Our pickers are characterised by simultaneous, freely programmable movements. This makes them vastly superior to pneumatic alternatives. And more energy-efficient too.

Dynamic

Fast sprue removal is another benefit you can enjoy with our INTEGRALPICKER V. The highly dynamic mould-entry axis can accelerate up to 20 m/s².

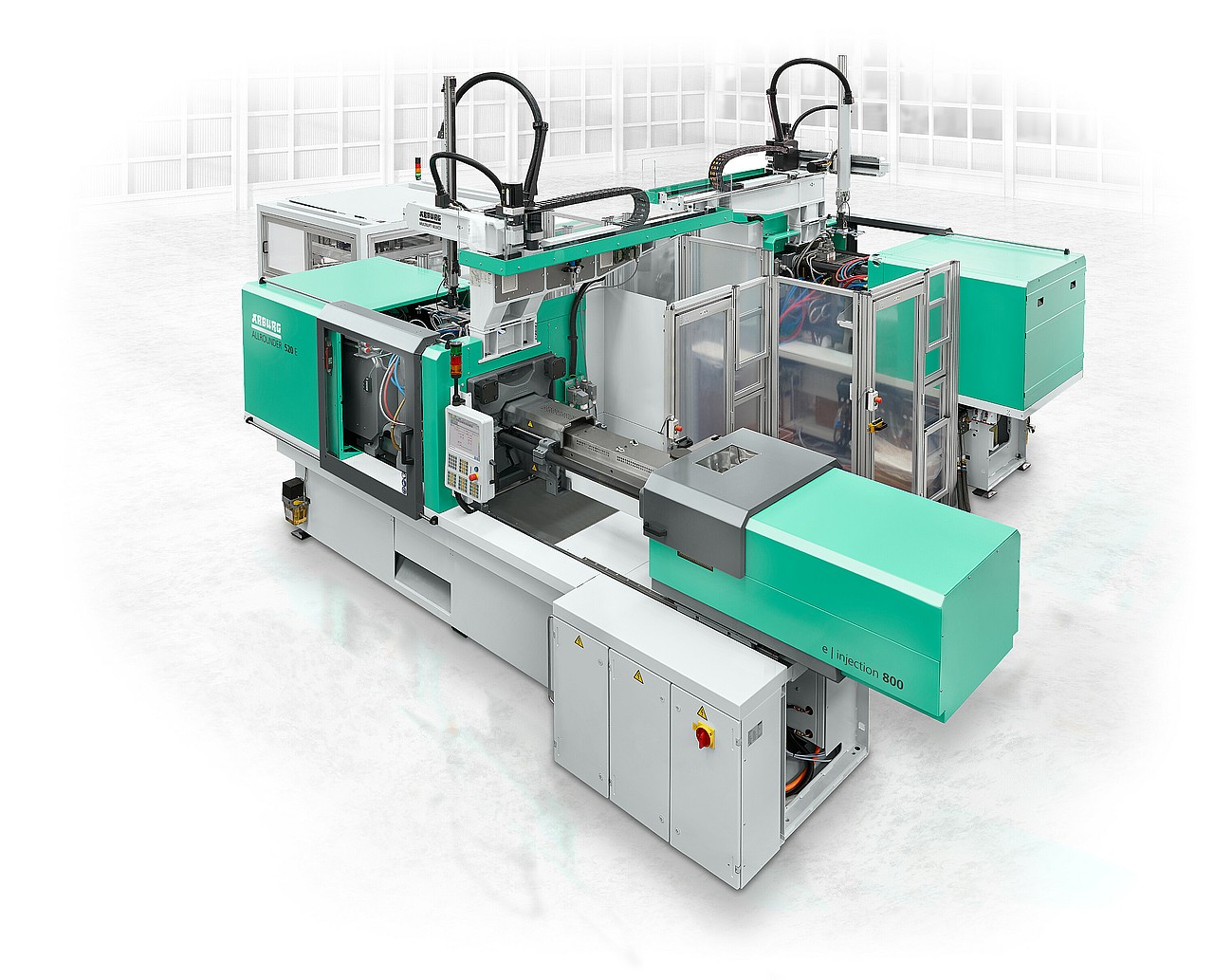

Automated production cells

Want to increase added value, optimise the injection moulding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

This might also be of interest

Automate your production tasks simply, reliably and quickly – with a turnkey project partner such as ARBURG, who can provide you with all-round support from the initial idea through to after-sales service.

Do you need highly adaptable, modular linear assistants for your removal tasks? Then our MULTILIFT robotic systems are perfect for you.

Make use of synergies for your injection moulding plant with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.