Benefits at a glance

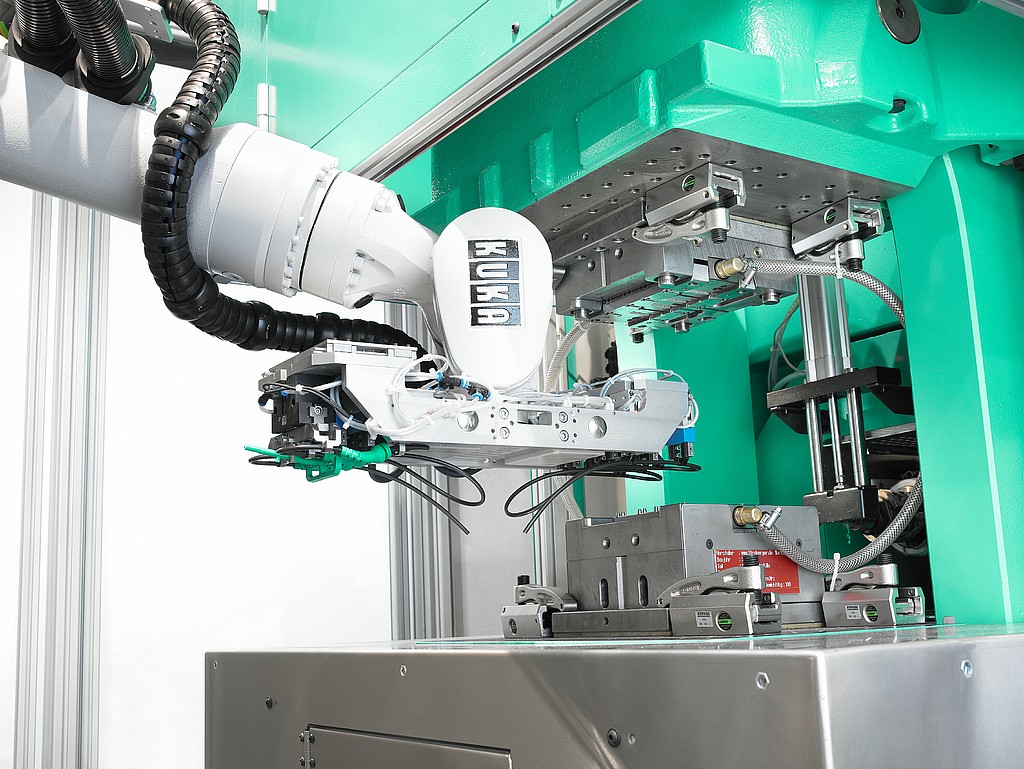

Plug and work

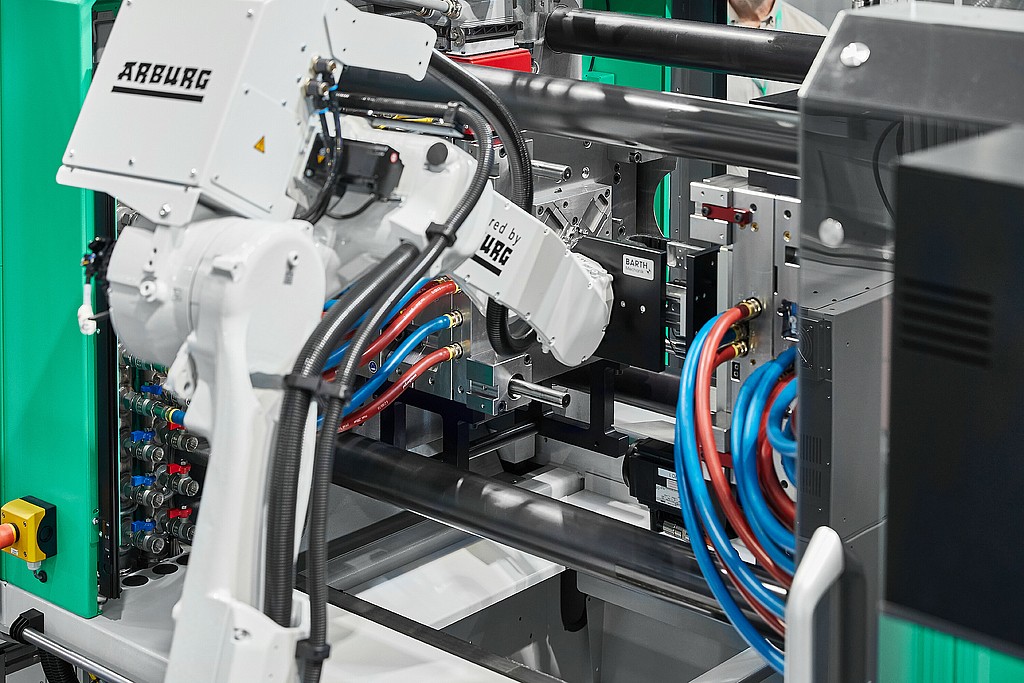

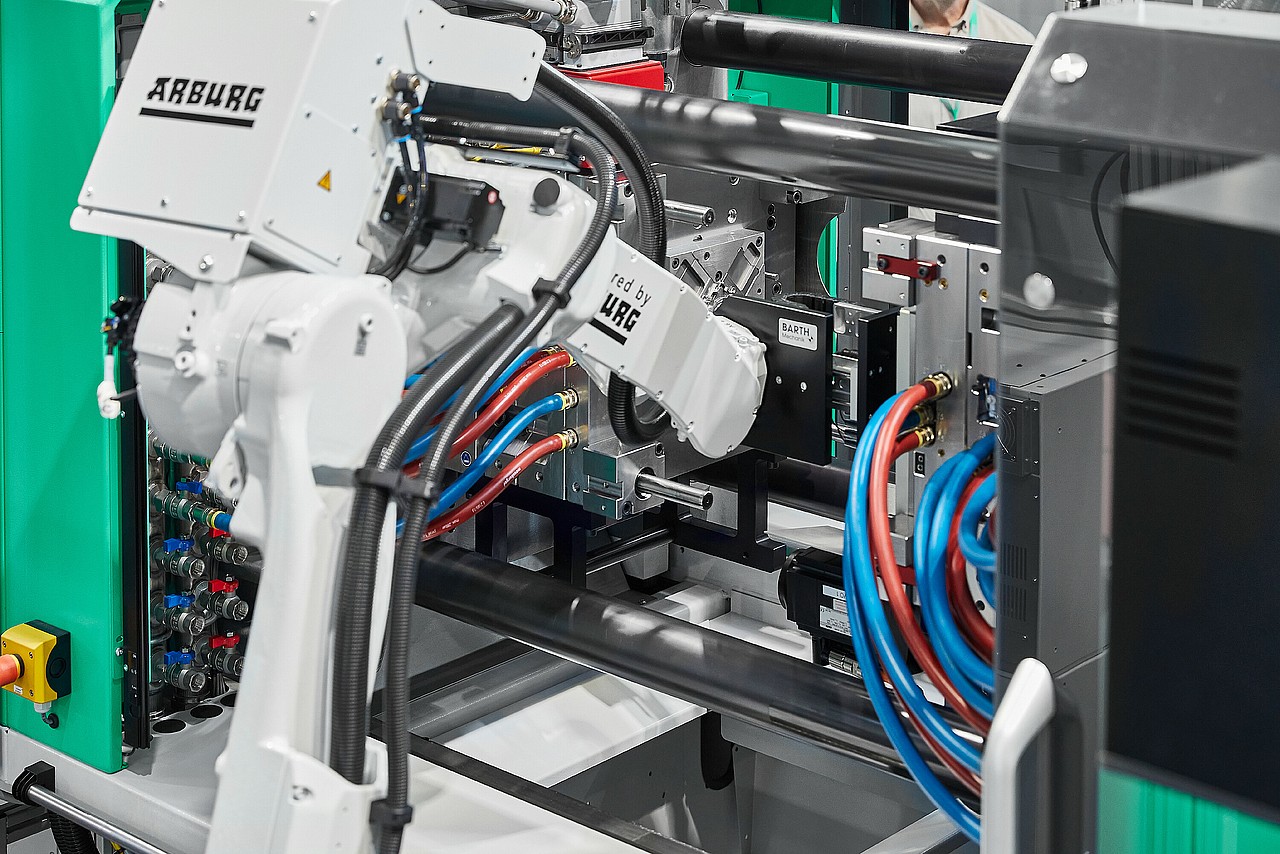

This is how you want to work – this is how our multi-axis robots work. Simply as a package solution. With pre-configured valve technology and standardised interfaces: up and running!

Integrated

You can program your robotic system directly via the ALLROUNDER control system and easily create your own sequences. What's more, there is a shared data set.

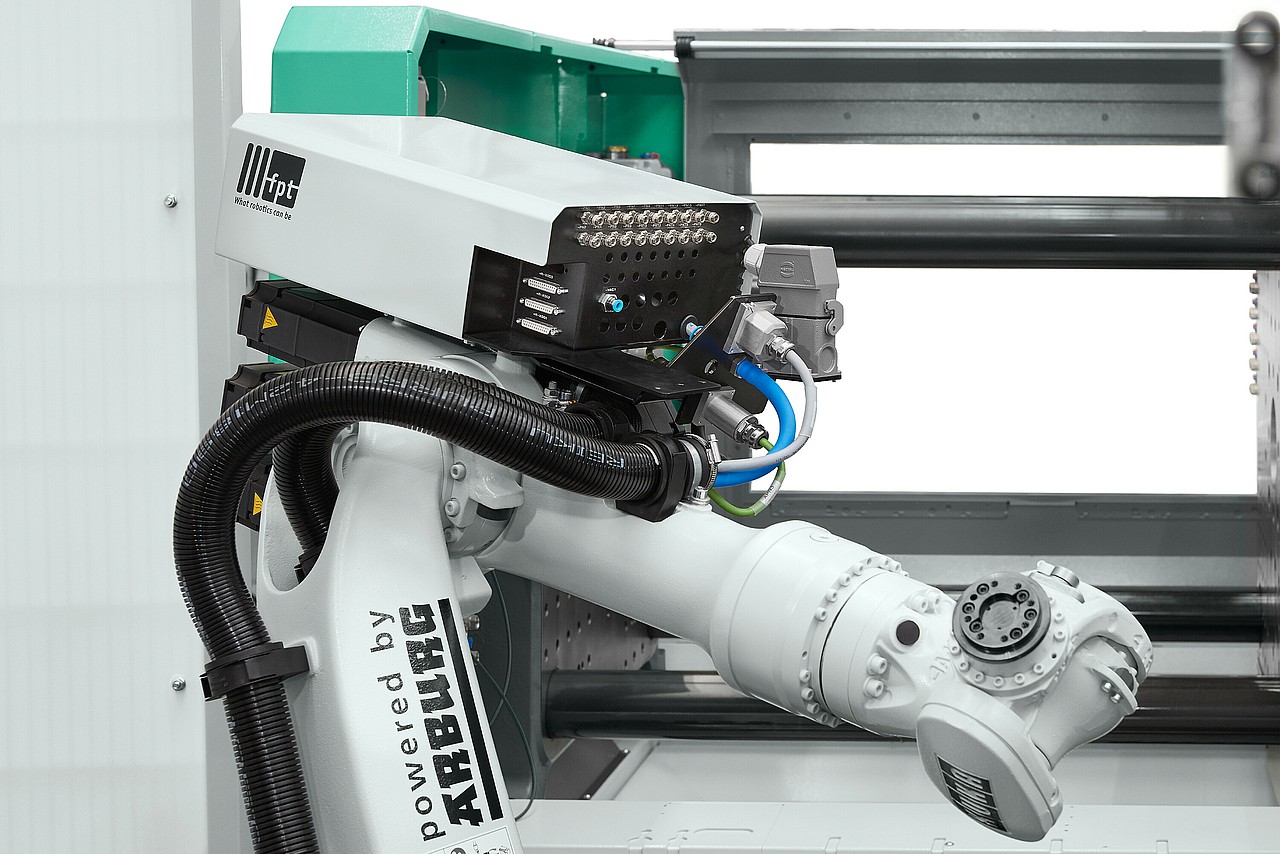

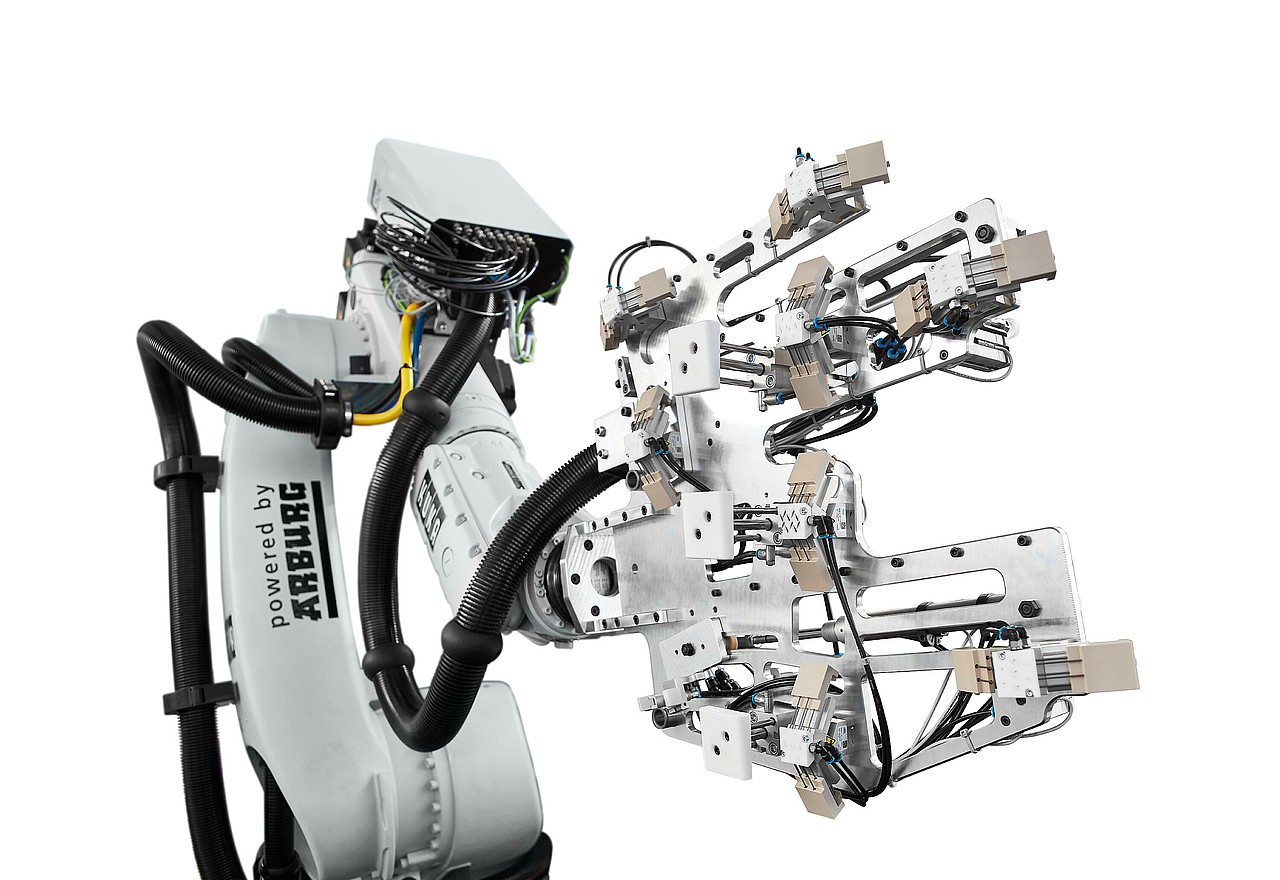

Agile

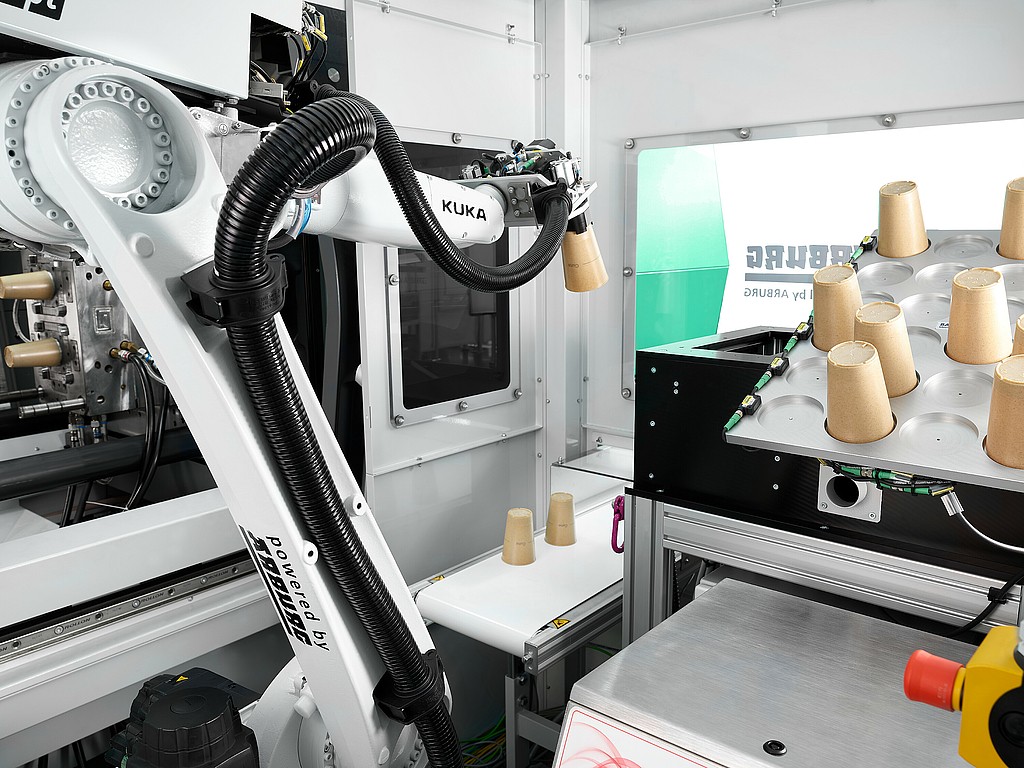

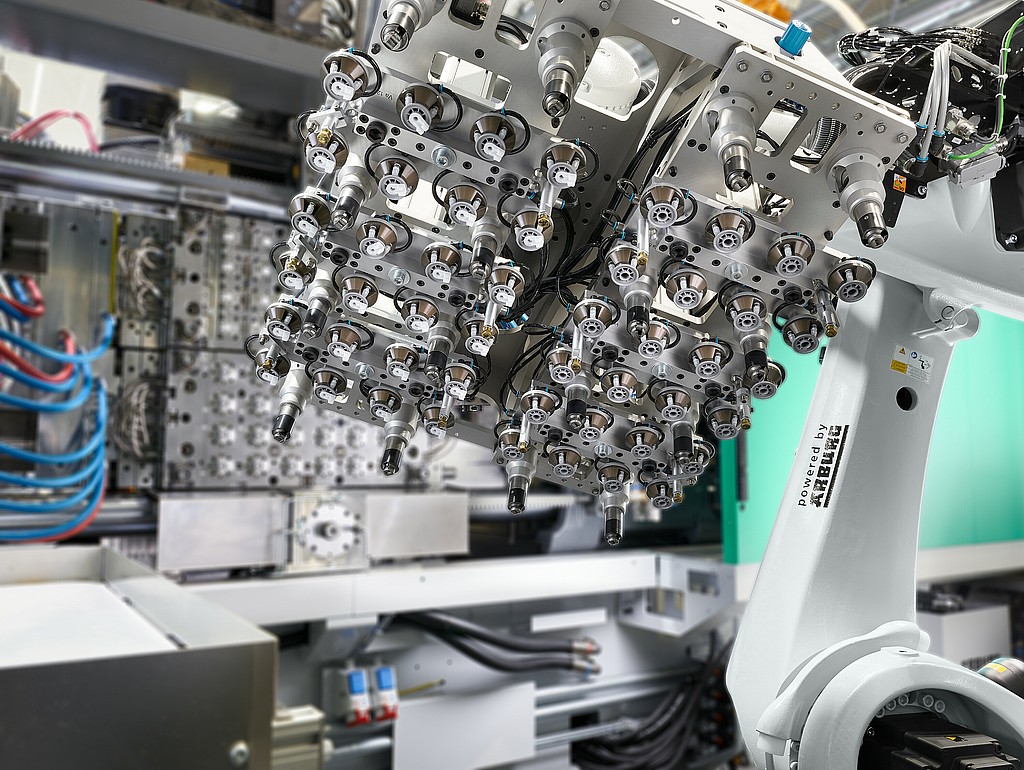

"Powered by ARBURG", our multi-axis robots are extremely flexible motion artists. For a high level of functionality in a small space.

Economical

Top quality and predictive maintenance. The robust and low-maintenance robot technology ensures a long service life, reduced maintenance costs and high availability.

Technical data

Sample components

Cable grommet

Flexible parts such as cables are individually prefabricated and inserted into the mould cavities with a six-axis robot. The length of the cable loops can be set flexibly.

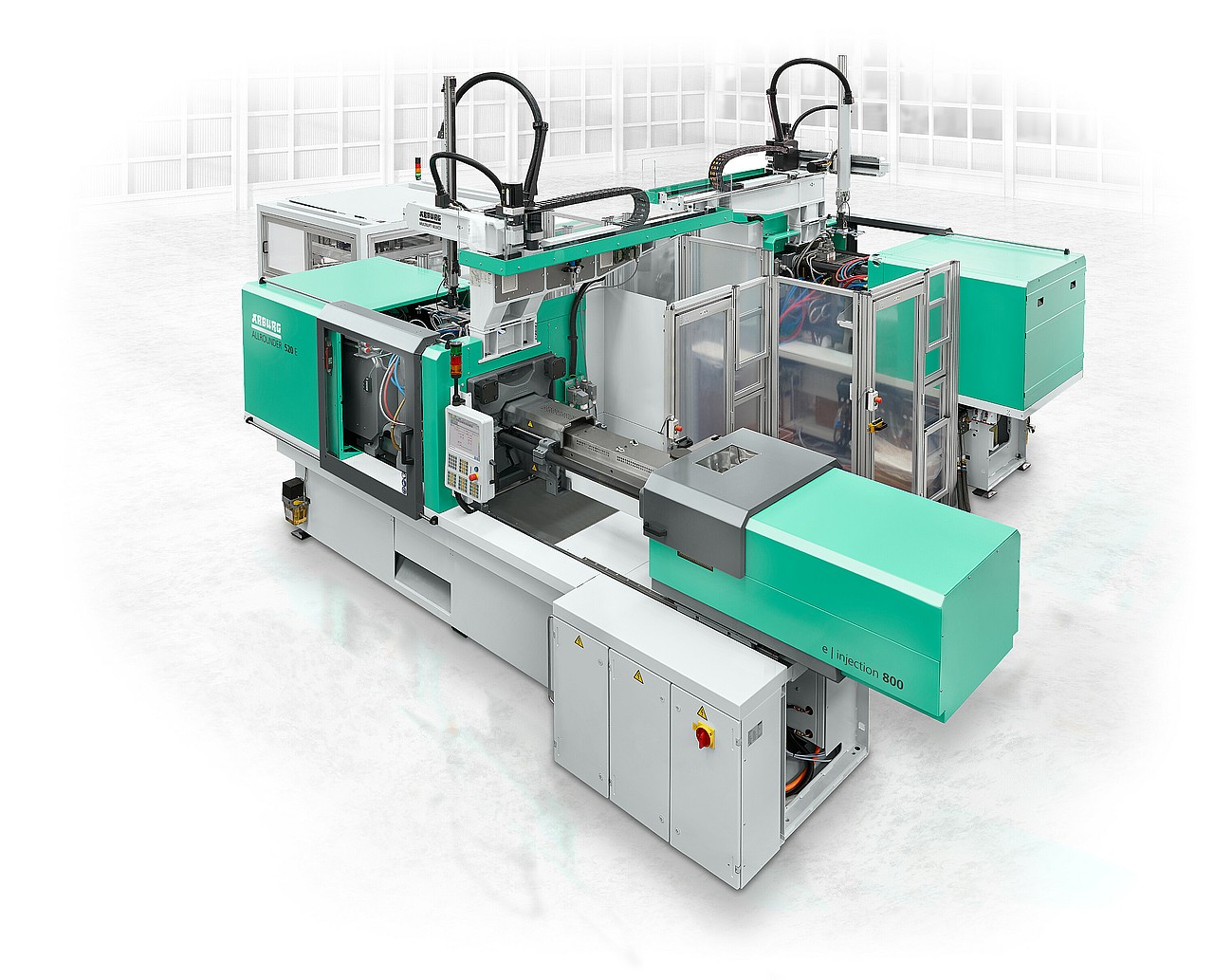

Automated production cells

Want to increase added value, optimise the injection moulding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

This might also be of interest

Automate your production tasks simply, reliably and quickly – with a turnkey project partner such as ARBURG, who can provide you with all-round support from the initial idea through to after-sales service.

Digitalise your injection moulding production to suit your individual needs. We have the right tools! For machines, automation and IT cross-linking. For maximum production efficiency and value creation.

Make use of synergies for your injection moulding plant with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.