Benefits at a glance

Optimised cycle times

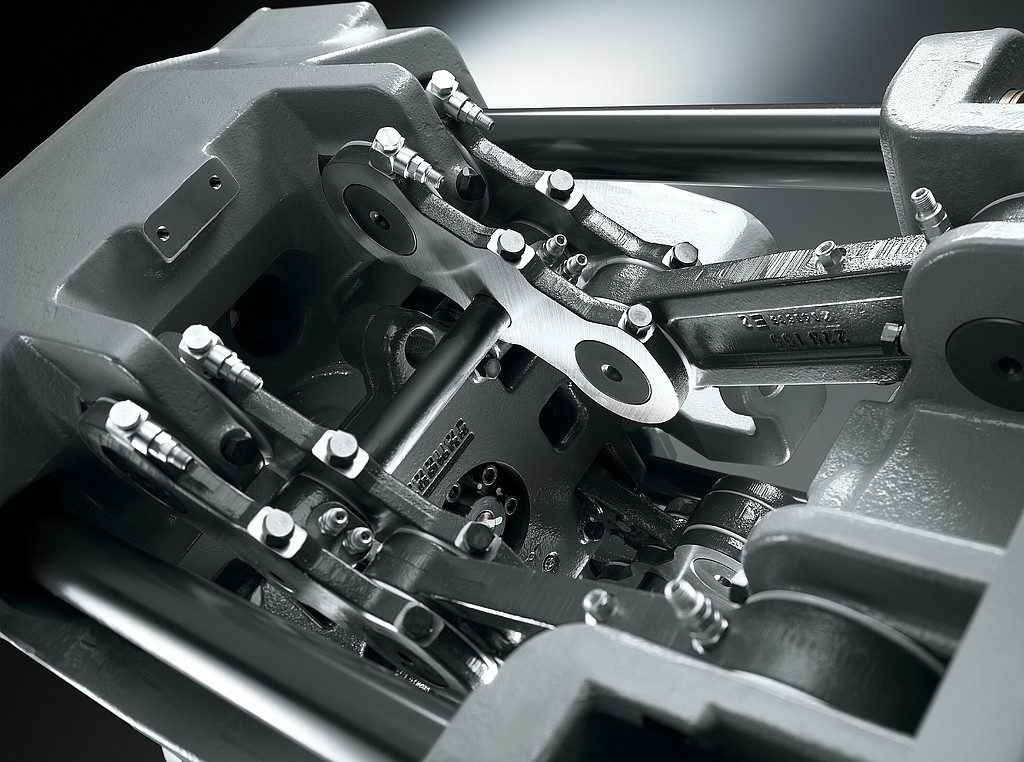

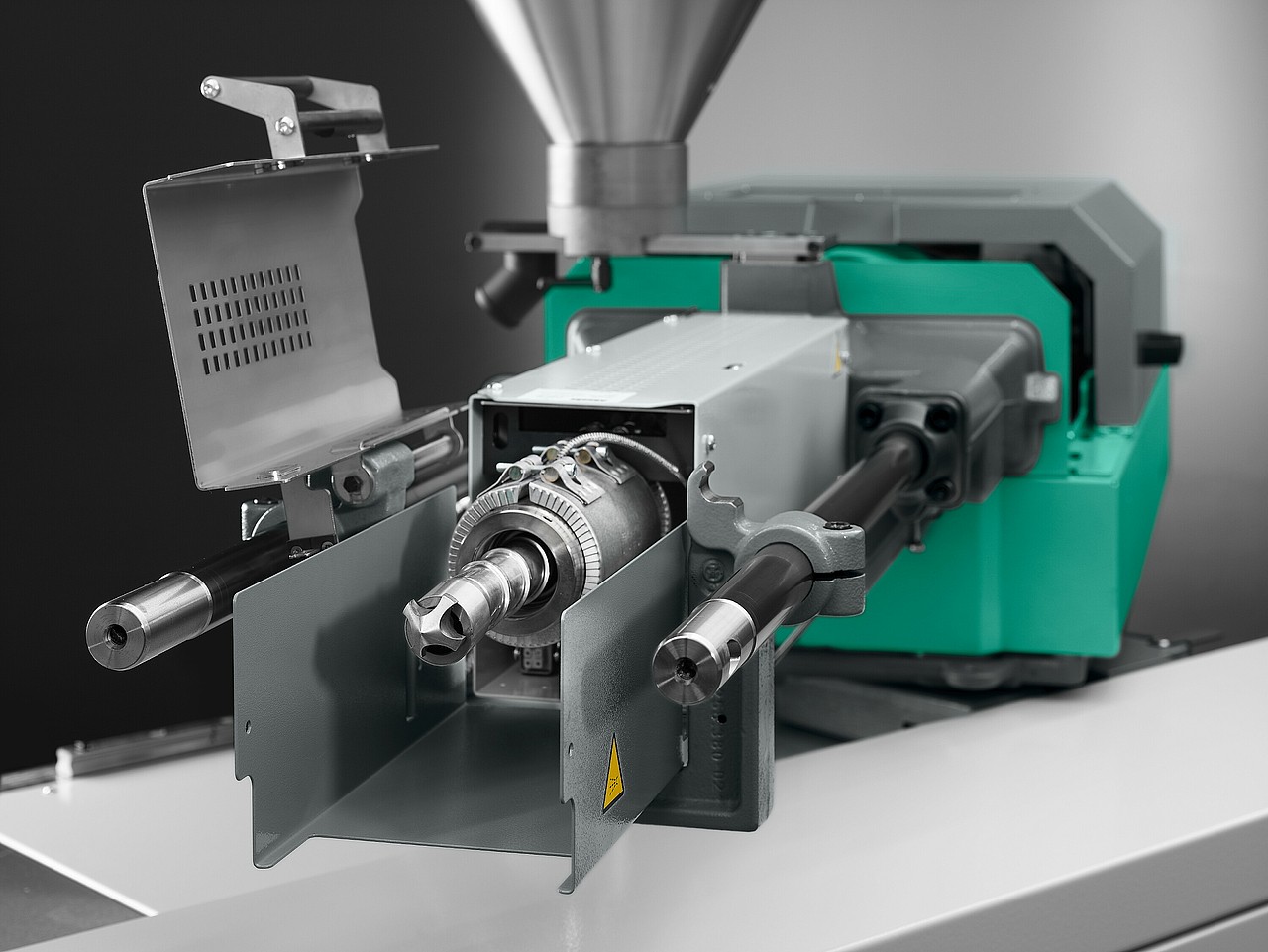

Fast cycles – The success principle of the hybrid model. Experience the interaction of servo-electric clamping unit and hydraulic injection unit featuring hydraulic accumulator technology.

Energy-optimised

Despite maximum performance, you can count on reduced energy requirements: thanks to servo-electric direct drive for dosing. Plus recovery of braking energy.

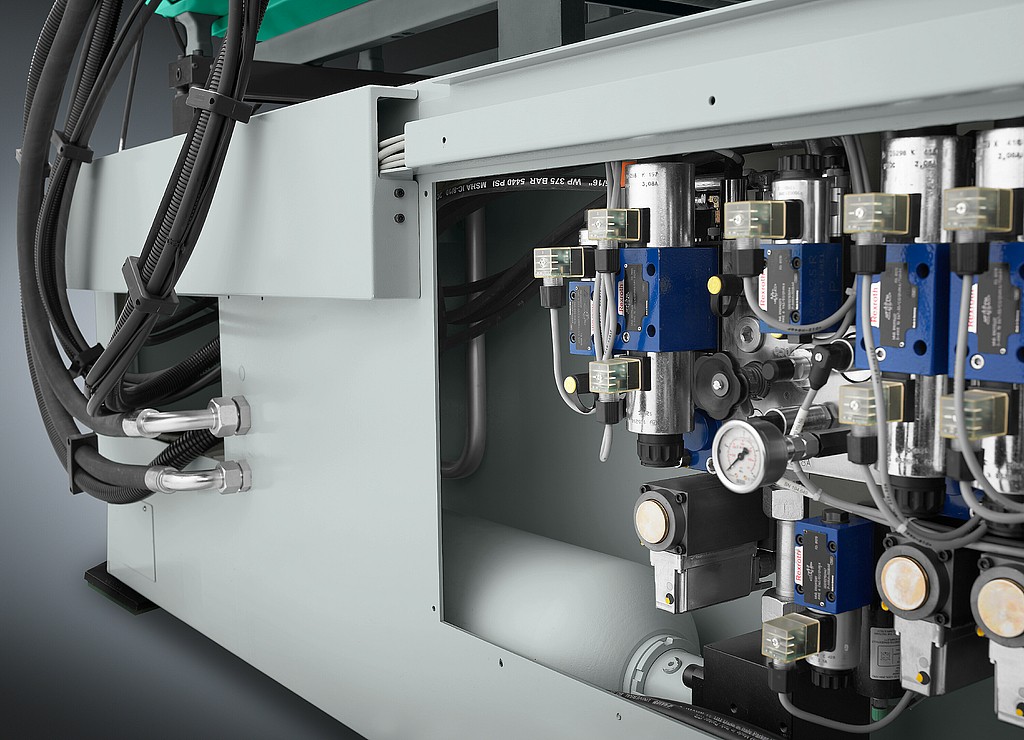

Dynamic

The dynamic hydraulic accumulator charge control automatically adjusts the pressure level to the current demand, in line with the process. This saves up to 40 per cent energy.

Industry-specific

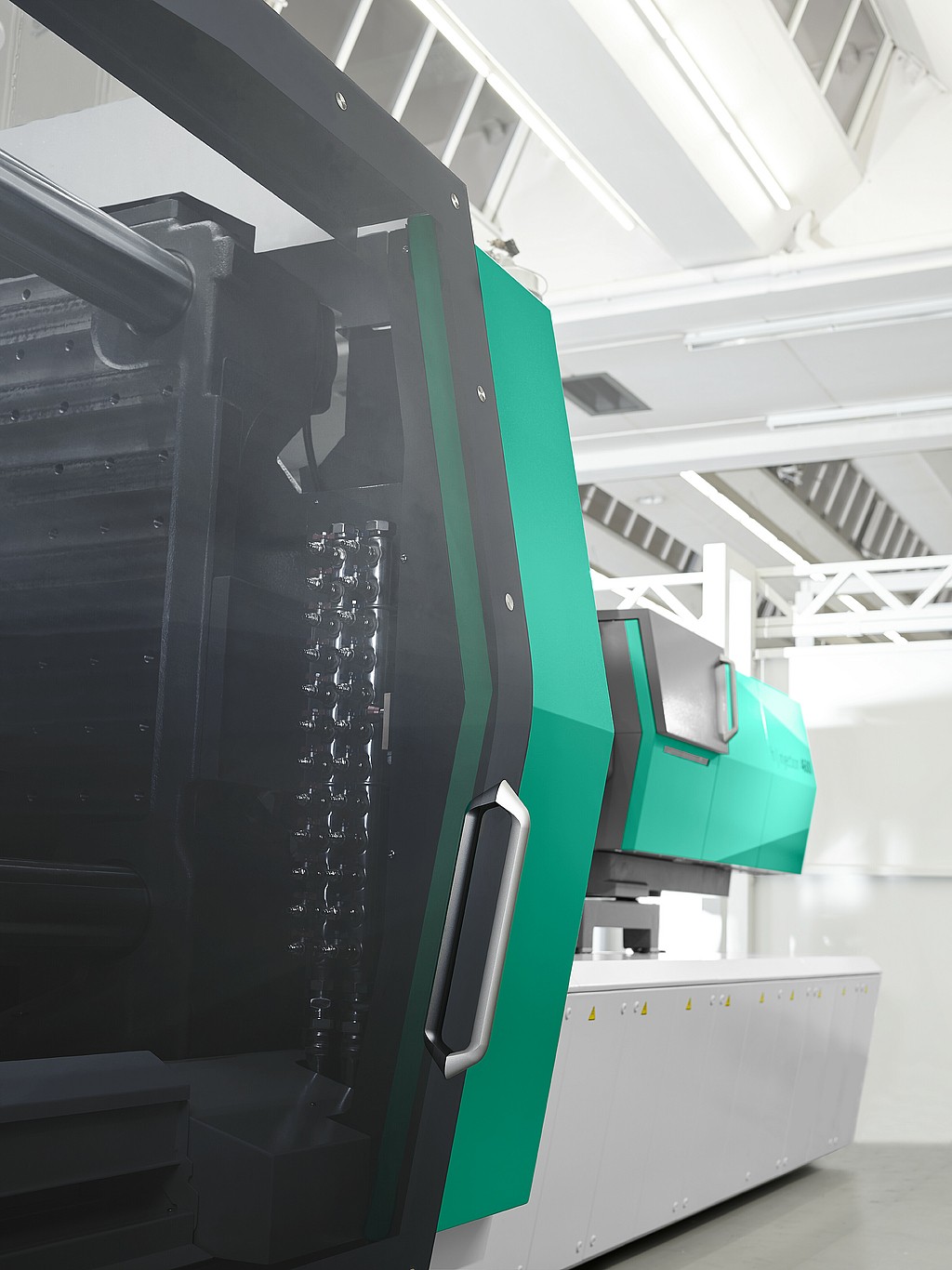

Precisely for your purposes – customer-specific, industry-specific. Also available in special packaging design. The modularity and individual equipment make it possible.

New machine technology

Experience the future with our new hybrid machine technology. Energy-saving, easy on resources and extremely efficient - this technology combines the best of the electric and hydraulic worlds. Enjoy speed and precision paired with power and dynamics.

Technical data

Part examples

IML tubs

In a cycle time of around 5s, an ALLROUNDER 1020 H in packaging version produces four thin-walled IML cups including lid. The product is made of chemically recycled PP.

IML buckets

5-litre IML buckets made from post-consumer recyclate (PCR) - produced on a HIDRIVE in packaging version. With the so-called HolyGrail technology for sorting by type.

Reels

Producing for the mobility sector efficiently in large batches: Around 18,000 reels per hour. The parts are separated according to mould cavities and packed ready for dispatch.

Training Courses

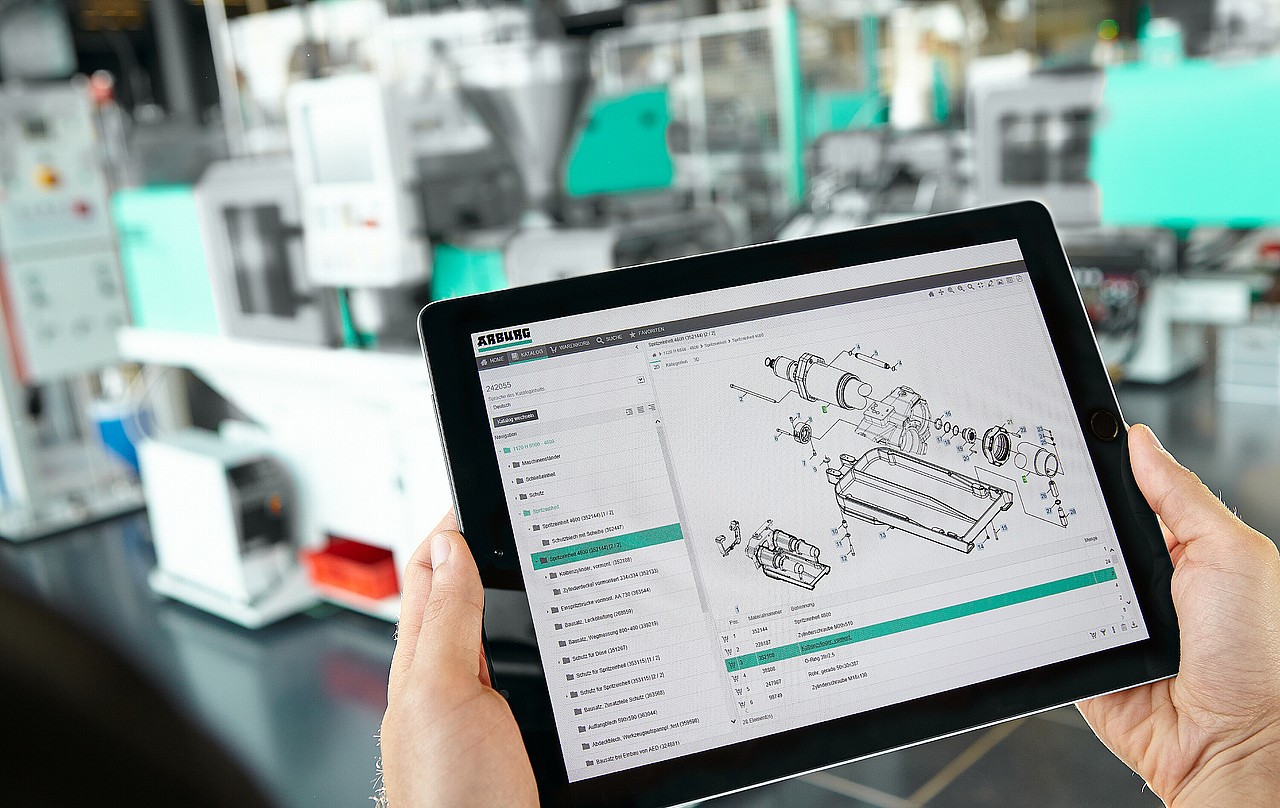

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also interest you

Thin-walled parts, IML products, screw caps? Our packaging machines combine FEM-optimised mould mounting platens, precise mould movements, high filling dynamics, short injection times and high plasticising flow rates.

Increase added value, optimise the injection moulding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As is already the case for many leading companies worldwide.

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Allow yourself be inspired to new ideas by our component selection.