ARBURG History

Milestones

Foundation of the company

1933 -1944"Fabrikle" (little factory)

1945 – 1952Durables

1953 – 1960Machine construction

1961 – 1970ALLROUNDER principle

1971 – 1979Controller

1980 – 1989International expansion

1990-1999Turnkey business

2000 – 2015Portfolio completed

2016 – todayDigitalisation

Start of the family company

Arthur Hehl is a trained precision mechanic and starts out as a self-employed tradesman. He builds a house in Lossburg for his small family.

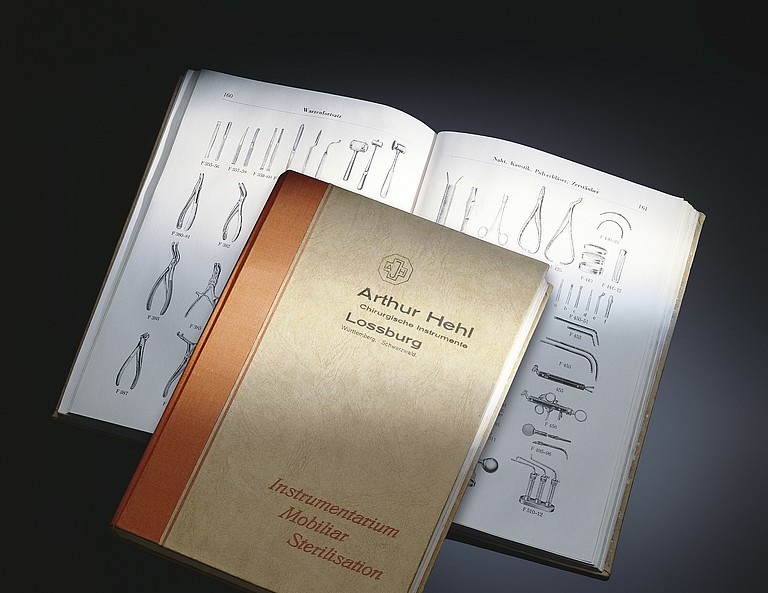

Factory for precision devices

Arthur Hehl begins to manufacture surgical instruments in the cellar of his home.

Work in the "Fabrikle”

The whole family works in the "Fabrikle", or "little factory", for which an extension is added to the house. After Arthur and his sons Karl and Gerhard Hehl are drafted into the war, mother Maria Hehl takes over the business.

ARBURG name and logo

Karl Hehl invents the company name in Normandy during the war. He combines the first syllable of his father's first name Arthur (AR) with the last syllable of the location Lossburg (BURG). The lettering with the distinctive typography characterises ARBURG to this day.

Durables needed

After the war, ARBURG begins manufacturing urgently needed everyday metal goods in 1948, including potato baskets, hairpins and clamping rings for baby bottles. Karl tinkers, while Eugen Hehl takes over sales.

Training company

ARBURG becomes a training company in 1949. Karl Hehl personally supervises the technical apprenticeships until 1957. The first apprentice is a machinist.

First injection moulding machine

In 1954 Karl Hehl develops his first small injection moulding machine for his own use in order to overmould the plug contacts on the flashguns. The plastic insulation protects against corrosion.

ARBURG machine construction

Demand is so brisk that the innovative "C1" machine goes into series production from 1956. With great foresight, Eugen Hehl begins to develop appropriate sales structures. In 1959, ARBURG is represented at the K trade fair in Düsseldorf for the first time.

ALLROUNDER principle

As early as 1961, ARBURG has the innovative idea of designing an injection moulding machine with a pivoting clamping unit and interchangeable injection unit: the ALLROUNDER idea is born.

Multi-component injection moulding

Modular: Combining a horizontal and vertical injection unit makes multi-component injection moulding possible in 1962. One of the first two-colour injection moulded parts is a telephone dial plate.

50 years of innovation

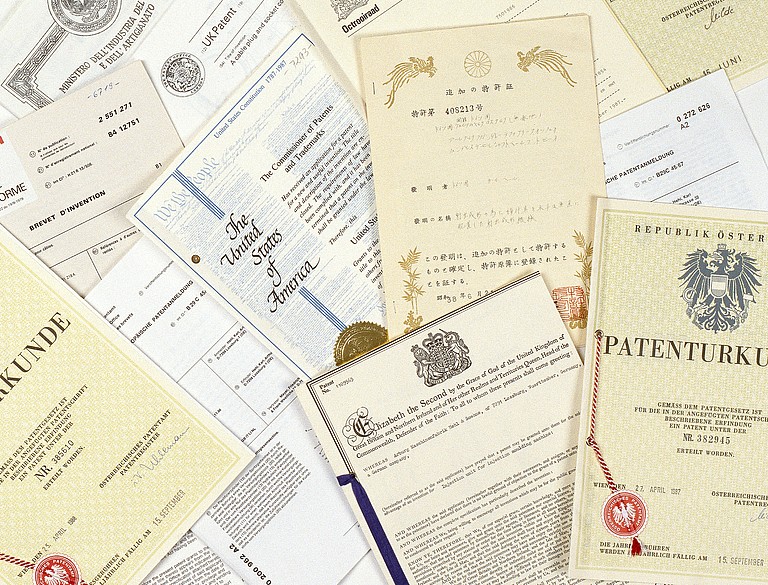

By 1973, ARBURG has sold more than 10,000 injection moulding machines and filed over 700 patents and registered designs. In 1975, an ALLROUNDER 270 H is the world's first injection moulding machine with microprocessor controller and hydraulic proportional pressure control valve technology.

IBM pilot company

In 1979, ARBURG becomes an "IBM pilot company" and in 1982 introduces the first injection moulding machine with on-screen control. The CMD series can be integrated into a fully automated production cell.

First international organisation

The first international ARBURG sales company is founded in France. Today, our employees provide first-class support directly on site – in around 100 countries worldwide.

ARBURG host computer system

A pioneering achievement is the invention of the ARBURG host computer system ALS – the first manufacturing execution system (MES) specifically for injection moulding companies. With ALS, machines can be cross-linked, processes monitored and configuration data documented.

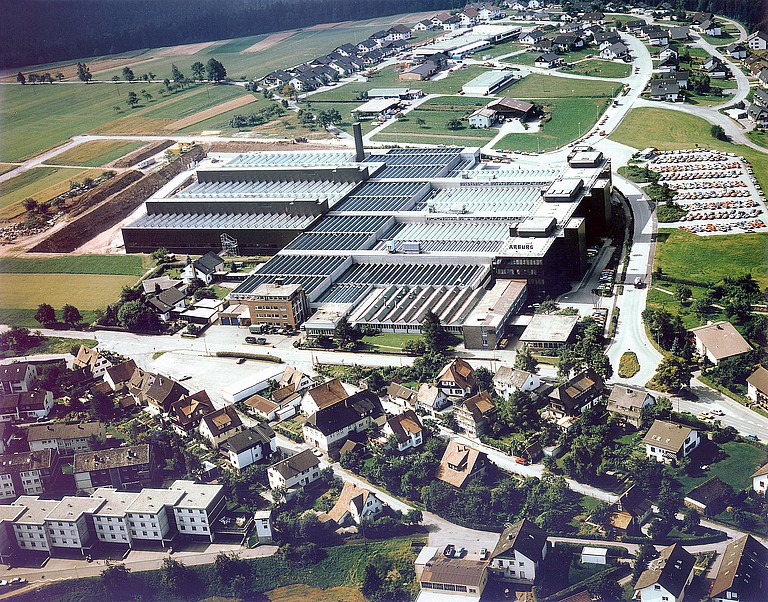

Over 1,000 employees

ARBURG employs over 1,000 people for the first time. A milestone is also reached in construction – the company premises now cover more than 100,000 m².

SELOGICA controller

The SELOGICA controller is introduced to the market and features impressive graphical sequence programming and automatic plausibility checks.

Turnkey projects

Since 1996, we have been offering injection moulding and automation technology from a single source as a primary contractor. The turnkey project department develops customised solutions based on a combination of machine and robotic system.

75th anniversary

To mark "75 years of the Hehl family company", ARBURG launches a new injection moulding machine – the ALLROUNDER C JUBILEE.

Electric ALLROUNDER

ARBURG adds electric injection moulding machines to its portfolio, which, like the hydraulic and hybrid ALLROUNDERs, can be expanded on a modular basis.

Generational handover

In 2005, the third generation of the family owners takes over the management of the company, in the form of Juliane Hehl, Renate Keinath and Michael Hehl (from right).

Customer Center

The 2,100 m2 Customer Center is opened in Lossburg. For individual support at the highest level. Customers can test machines and moulds here in a professional environment. Just like in the ARBURG Technology Centers around the world.

Death of Karl Hehl

In 2010, Senior Partner Karl Hehl dies at the age of 87. For more than six decades, his influence as a technical specialist was decisive in shaping the business, and, with his brother Eugen, turning ARBURG into a global leader in injection moulding.

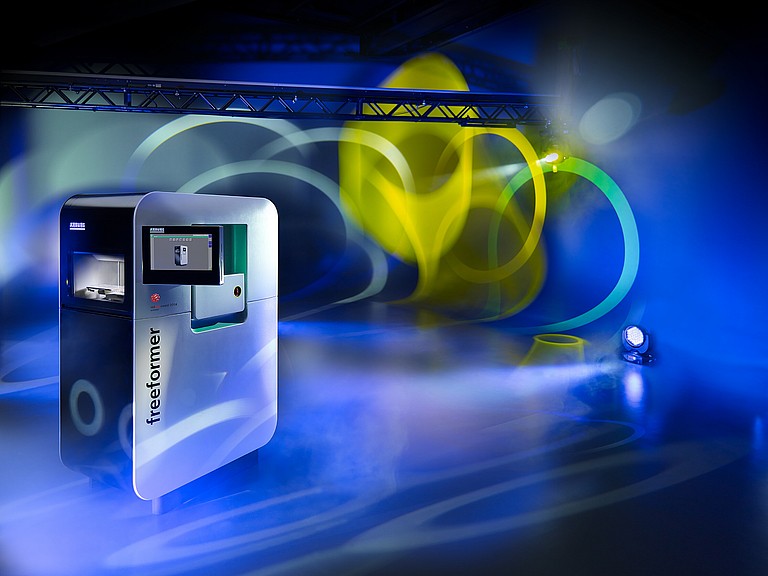

ARBURG Plastic Freeforming (APF)

The freeformer and ARBURG Plastic Freeforming (APF) celebrate their world premiere. The industrial 3D printer opens up brand new possibilities in additive manufacturing, processing standard plastic granules into functional components without the need for moulds.

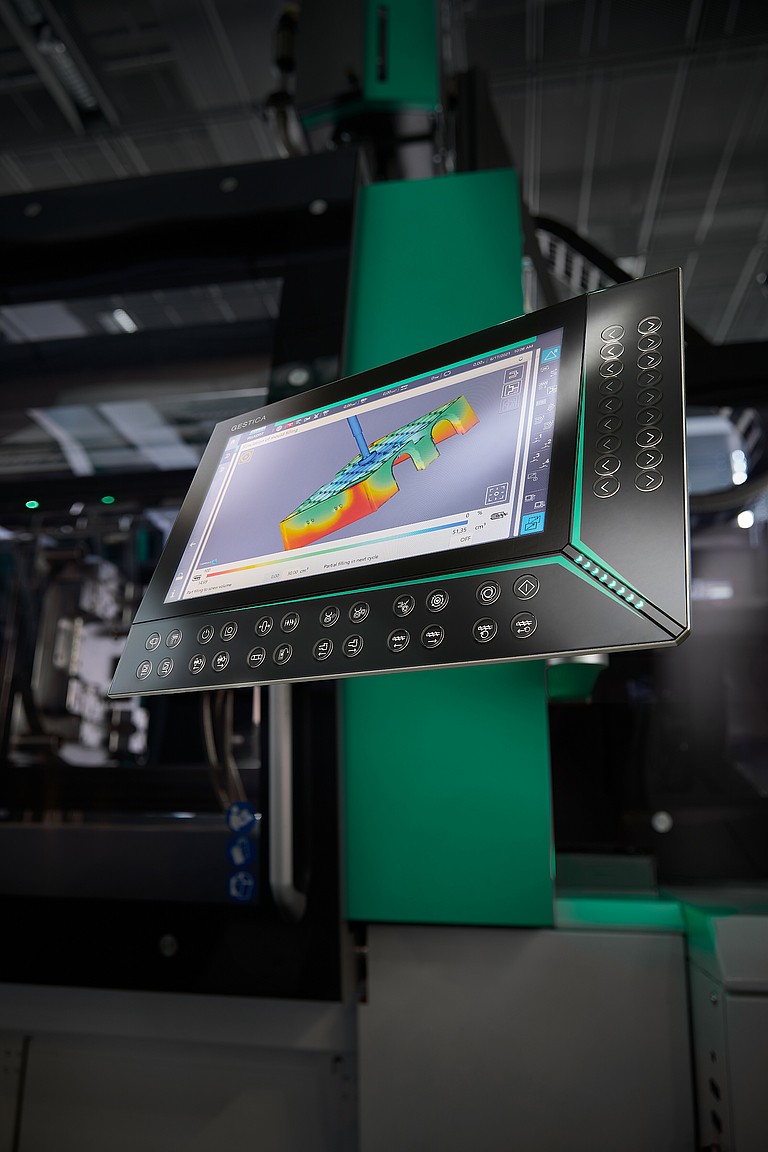

GESTICA controller

ARBURG presents its controller of the future, which reflects the "look and feel" of smart mobile end devices. New features include a full HD screen, a pivoting control panel and smart operation via the EASYslider.

Three awards for training

ARBURG is the first company in Baden-Württemberg to receive three quality certificates for its excellent training: the LQW certificate, the "1A Ausgezeichneter Ausbildungsbetrieb" quality seal for outstanding training companies, and DIN ISO 29990.

Customer portal

The "arburgXworld" customer portal brings together all the company's digital products and services, enabling ARBURG to drive forward the digitalisation of services and business processes.

Training Center

The 2,100 m2 Training Center in Lossburg offers a comprehensive programme for digitalised learning in theory and practice. Its interactive training courses and seminars are inspiring.

Addition to the family

In 2020, the ARBURG partners take over innovatiQ, a manufacturer of 3D printers – then in 2021, AMKmotion, an expert in electric drives, joins the ARBURG family. As a result, ARBURG now has the complete drive train in-house.

Sustainability Report

ARBURG publishes a Sustainability Report for the first time. And provides information worldwide on the long-term sustainability of the company's actions and business operations.

Centenary celebration

2023 marks 100 years of the family company. From "Fabrikle" to the world's leading machine manufacturer in plastics processing. ARBURG celebrates this fantastic anniversary at its locations around the world.

ARBURG: The right partner for your plastic processing needs

Injection moulding machines, additive manufacturing, robotic systems, process control, digitalisation – ARBURG offers you everything from a single source. Individually tailored to your plastic parts production.