Benefits at a glance

Collected

Turning big data into smart data: the ATCM SCADA system collects relevant process and quality data and forwards it to an evaluating system. This is based on the component ID.

Cross-linked

ATCM has an IT link to the production cell and is connected to higher-level analysis systems such as an MES. Turning big data into smart data.

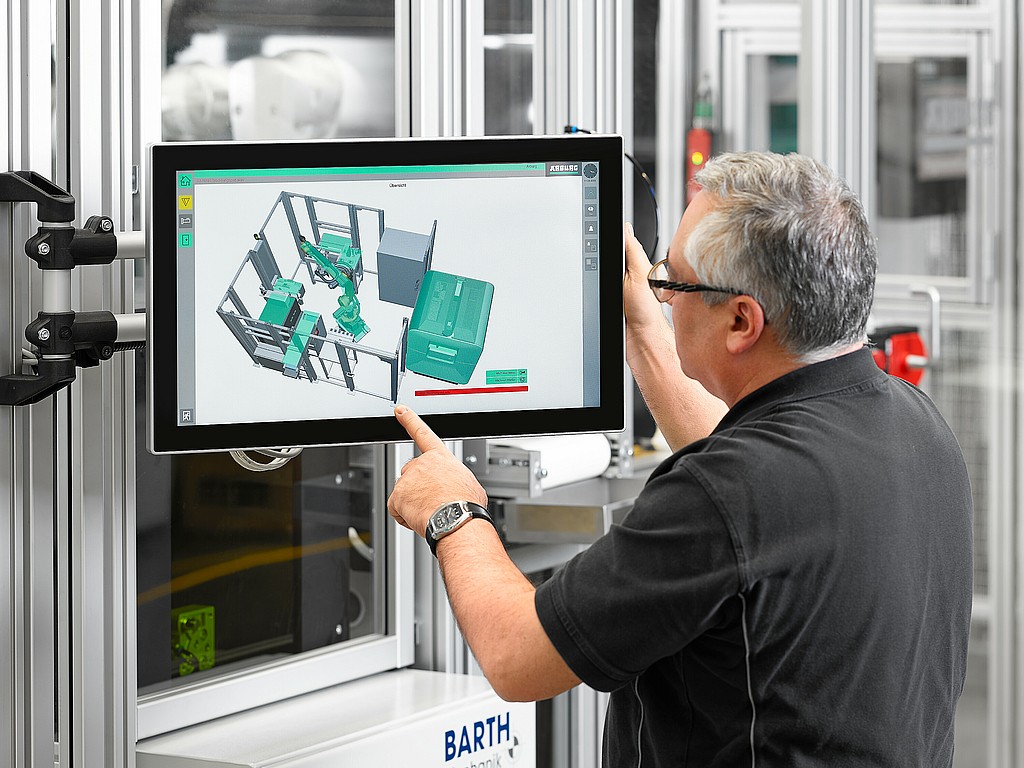

Visualised

ATCM can visualise important functions of complete production cells, such as protocol graphics, system statuses, alarms, and results of camera inspections.

Coordinated

You can also use ATCM to coordinate various processes independently of the injection moulding cycle, for example, to eject components for quality inspection.

Areas of application

Traceability

Produce cost-effectively and reliably! Fully traceable, part-specific and seamless production from one end of the process to the other. Our ATCM for turnkey systems has been designed precisely for this purpose.

Digital product passport

In a "smart" turnkey system, each product receives an ID and an R-cycle code. ATCM collects all the data in real time and consolidates it on a part-specific basis. This allows the cups to be traced and provided with a digital product passport.

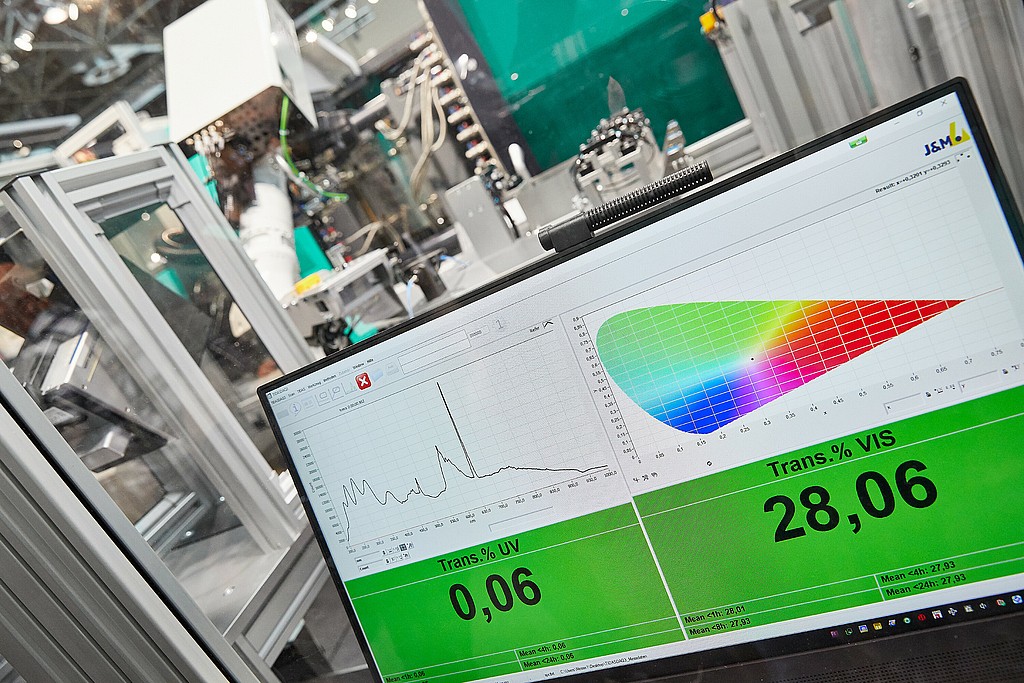

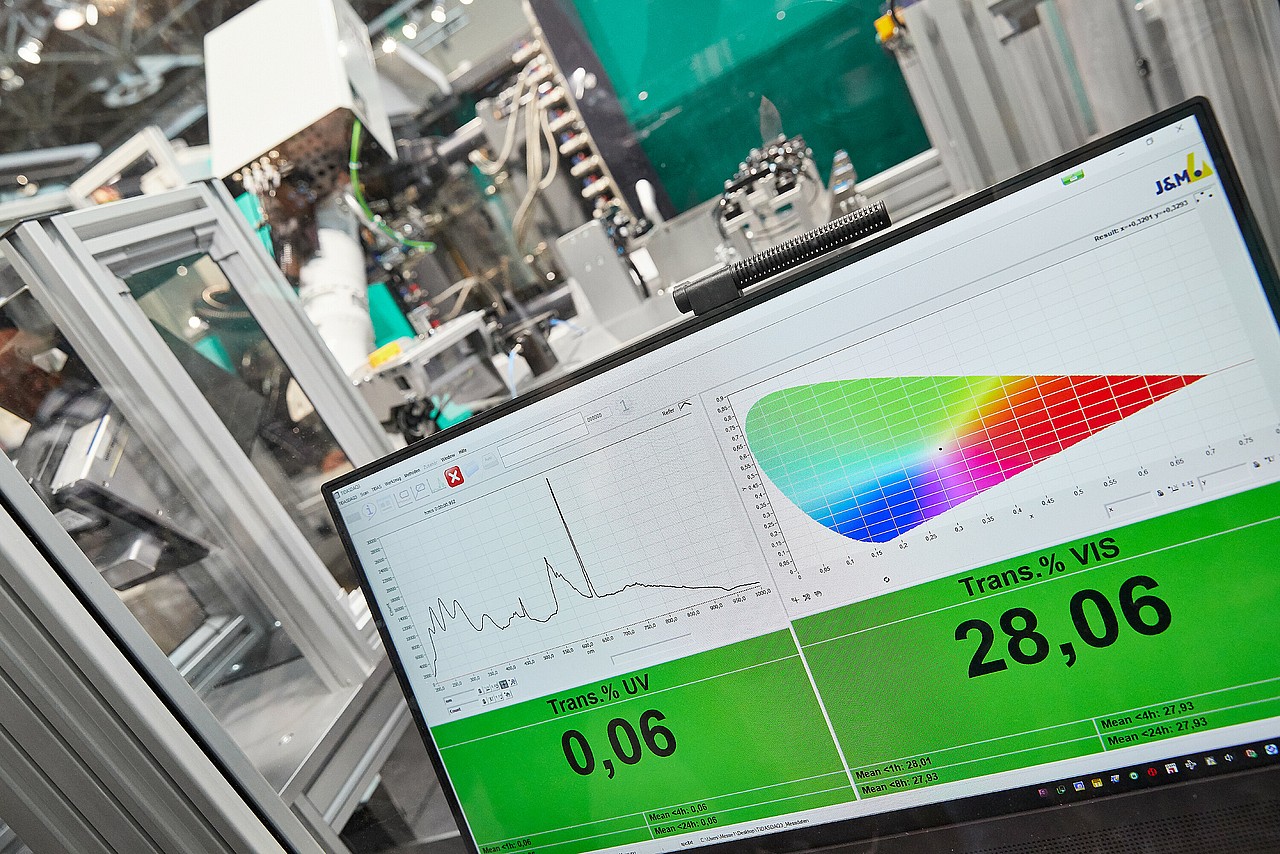

Quality data

In the production of UVEX ready-to-wear glasses, ATCM stores part-specific data from the injection moulding process and combines it with the results of the optical characteristics check. Important part-specific data can be retrieved at any time.

This might also be of interest

Powerful information hub: You can plan and control your entire production system with the ARBURG host computer system (ALS), our modular production management tool.

Are you looking for traceability, production on demand, and circular economy? Then our arburgXworld customer portal offers you unique digital added value.

Make optimum use of resources and reduce unit costs: Our solutions enable you to achieve maximum productivity with minimum operating costs, resulting in high cost-effectiveness.