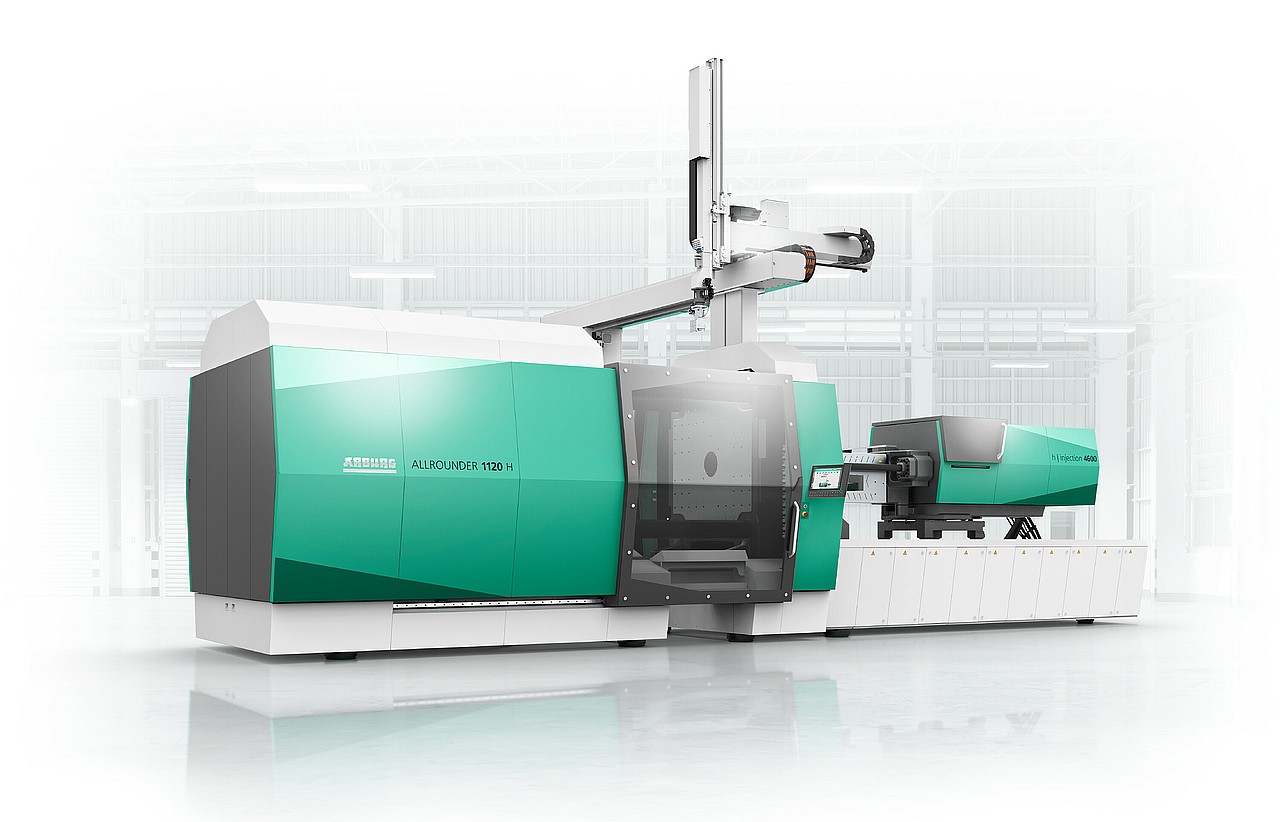

High-performance

We have combined electric speed and precision with hydraulic power and dynamics. So that you can manufacture reliably, in a highly productive and energy-efficient manner.

Superior

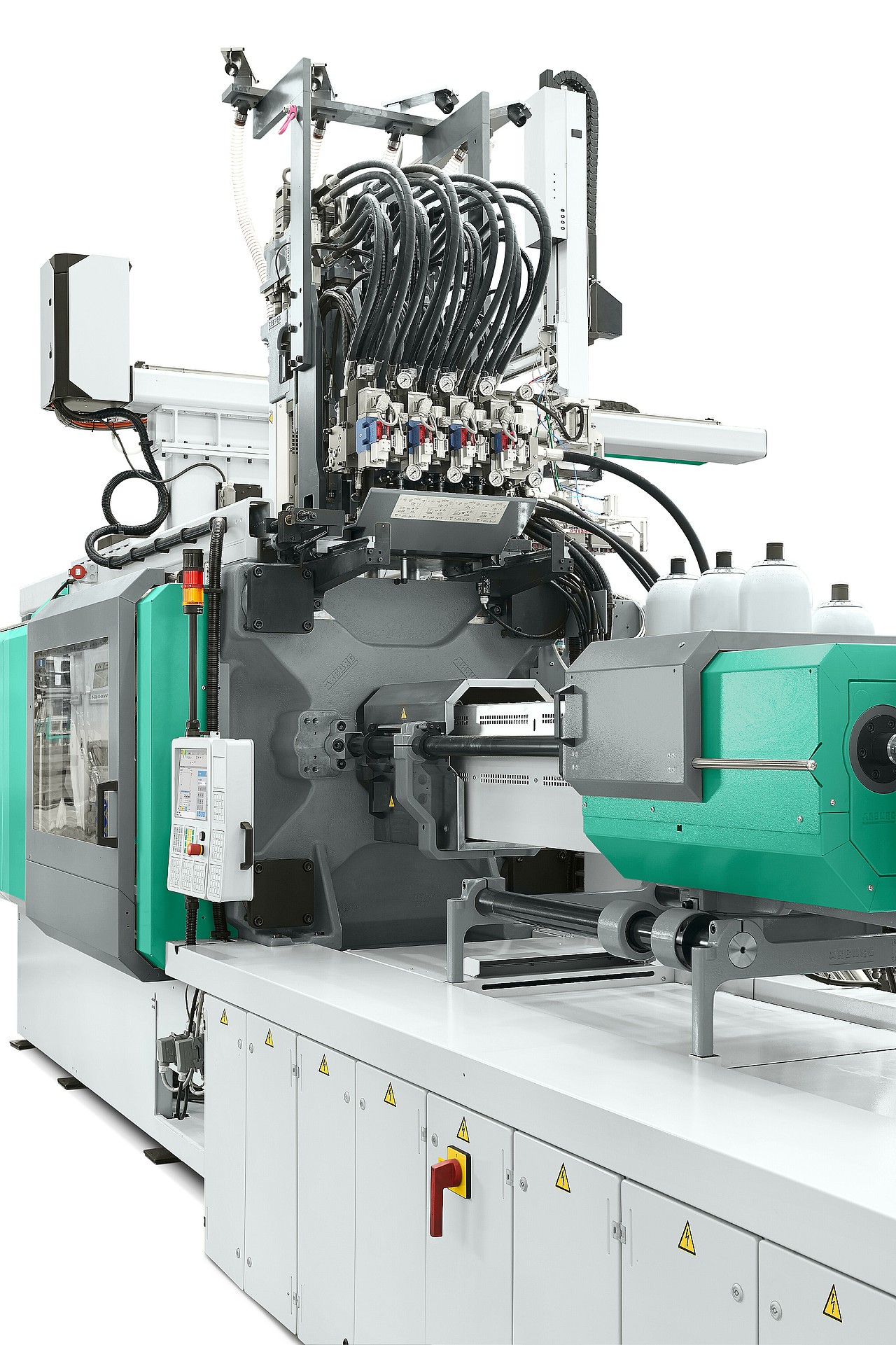

Servo-electric clamping units combined with large injection units featuring hydraulic accumulator technology. All movement axes operate completely independently of one another.

Cost-effective

Productive work with maximum availability and minimum set-up time and maintenance - that is what sophisticated ARBURG technology can do for you.

Benefits hybrid ALLROUNDERs

Reduced cycle times

Reduced cycle times

Simultaneous machine movements combined with extremely short dry cycle times of the servo-electric clamping units, "flying-start" injection, cycle-overlapping dosing

Large injection volume

Large injection volume

Proven hydraulic accumulator technology and "aXw Control ScrewPilot" for reproducible injection, high injection volume flows

Reduced energy requirement

Reduced energy requirement

Up to 40 % energy requirement resulting in high energy efficiency, servo-electric drives for mould movement and dosing, recovery of the braking energy, power-adapted pumps

Smart control system

Smart control system

Intuitive graphical user interface, unique plausibility check, comprehensive assistance packages, compatible controller technology

Series

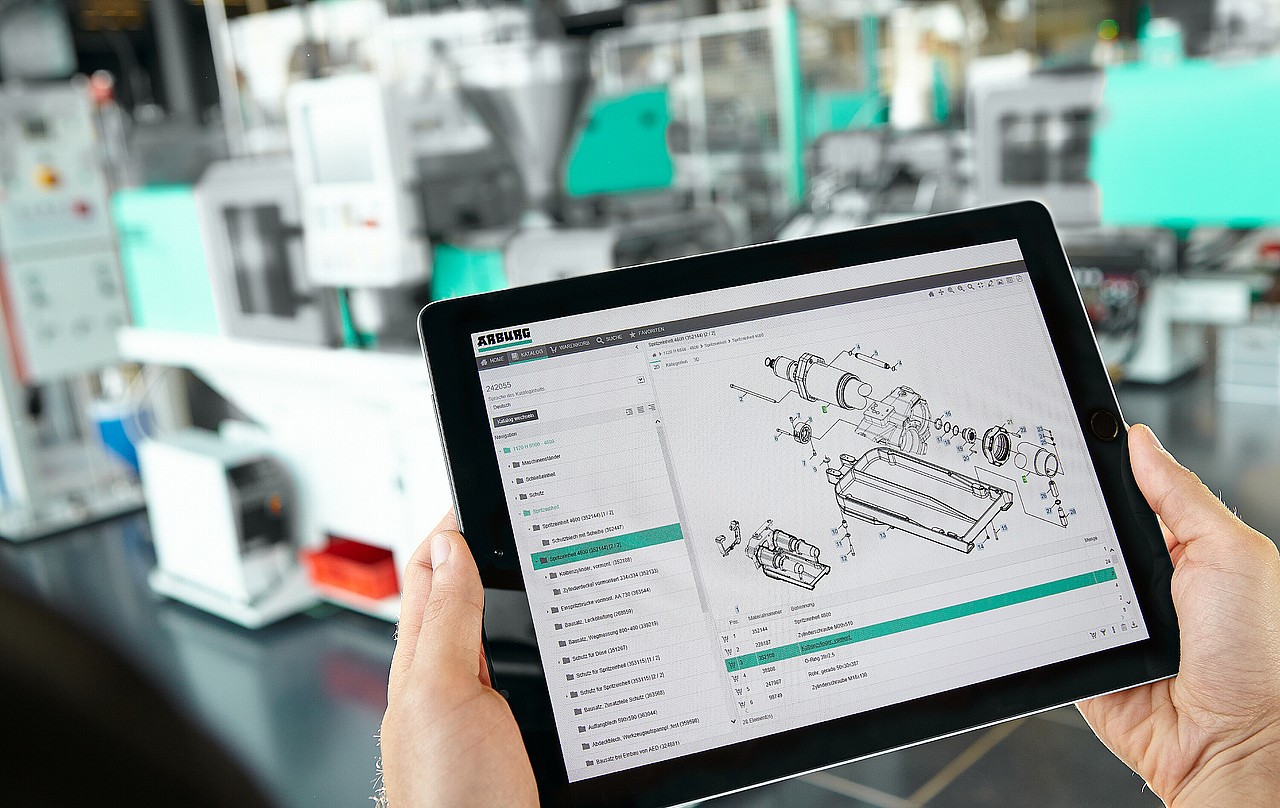

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also interest you

From practical experience – for practical use, that's how we share knowledge. You benefit from our know-how. Targeted, fast, collegial. With our machines, for your purposes.

Electronics, medicine, mobility, packaging, complex components for a wide range of sectors and industries. This is where you excel. So do our machines and solutions.

In a wide variety of industries and applications, our customers achieve great things, demonstrate a spirit of innovation and produce parts that long seemed impossible. Solutions from ARBURG make it possible.