Benefits at a glance

Forming

The PIM process combines the forming process of injection moulding with the properties of metals and ceramics. For complex moulded parts in high-volume production.

Dispensable steps

With the PIM process, you can dispense with extra expensive assembly and joining steps. This allows you to work quickly and efficiently. Use the alternative to milling or eroding.

Economical

Another reason why powder materials might be of interest to you is that materials that are difficult to machine and therefore expensive, such as titanium, can be formed very cost-effectively.

Expandable

Do you have an ALLROUNDER in your company? Then in principle it is also suitable for powder processing. We tailor the technology to your individual requirements.

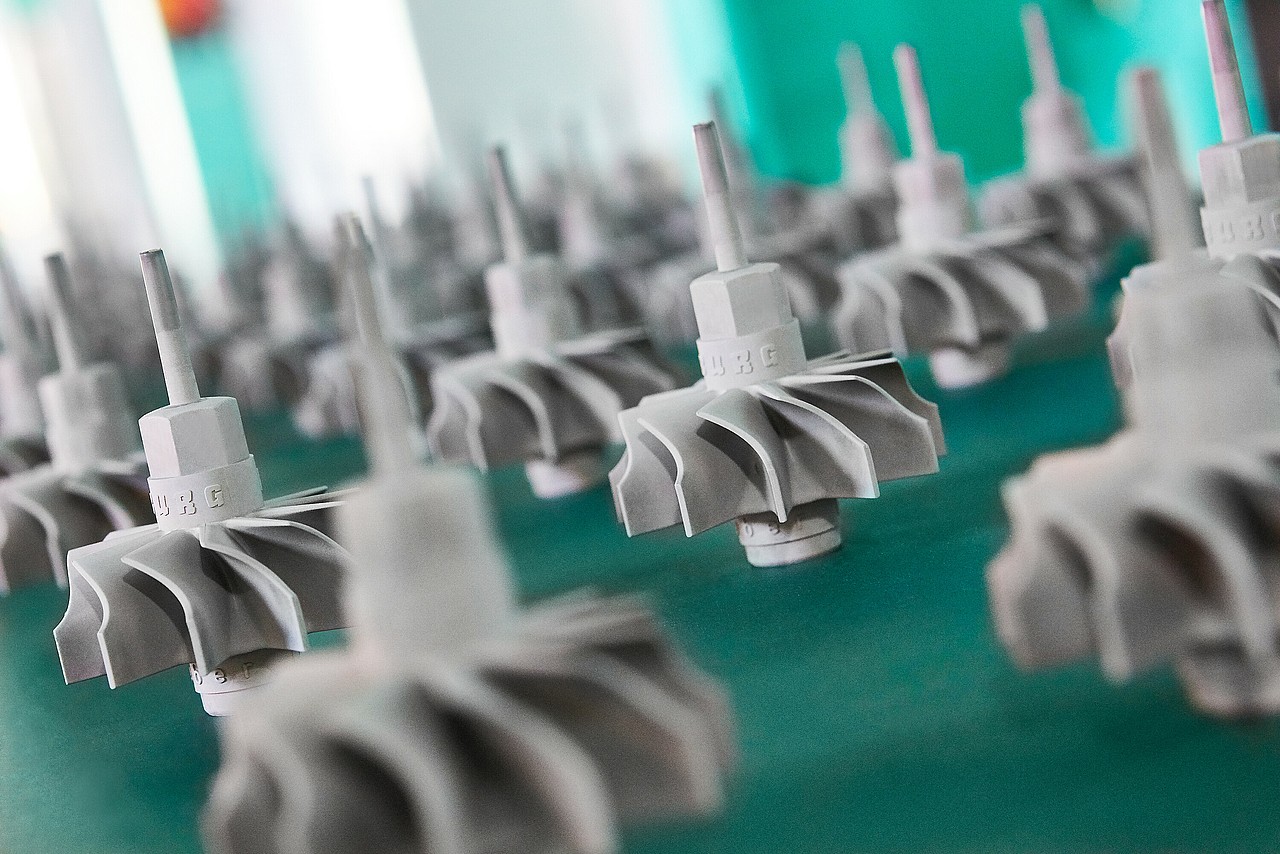

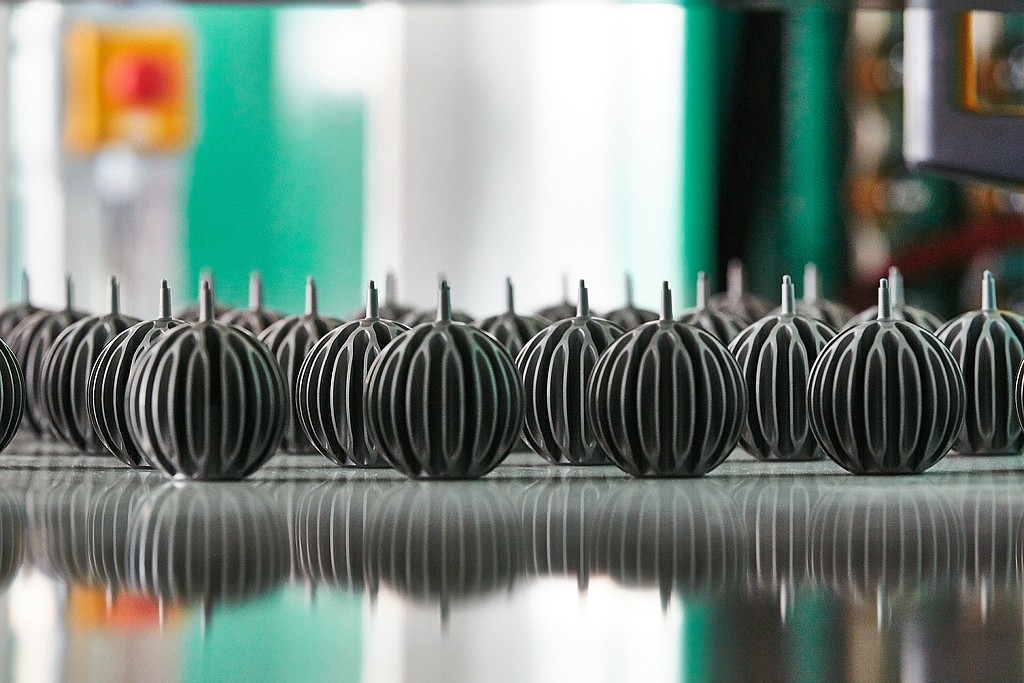

Sample components

Heat sinks

Manufactured close to the final contour, bionically optimised heat sinks for LED lighting make use of the huge scope for forming offered by powder injection moulding.

Ferrules

Ceramic ferrules connect glass fibre bundles for data transmission. Precise execution of the through hole, which is only 0.125 mm in size, is crucial. CIM achieves tolerances of +/- 10 µm.

This might also be of interest

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

Injection moulding complex components made of metal (MIM) or ceramics (CIM)? No problem: powder injection moulding (PIM) offers great design flexibility.

Take advantage of our expertise – from moulded part design to mould and machine configuration. And application technology, for example in our Customer Center.