Efficient

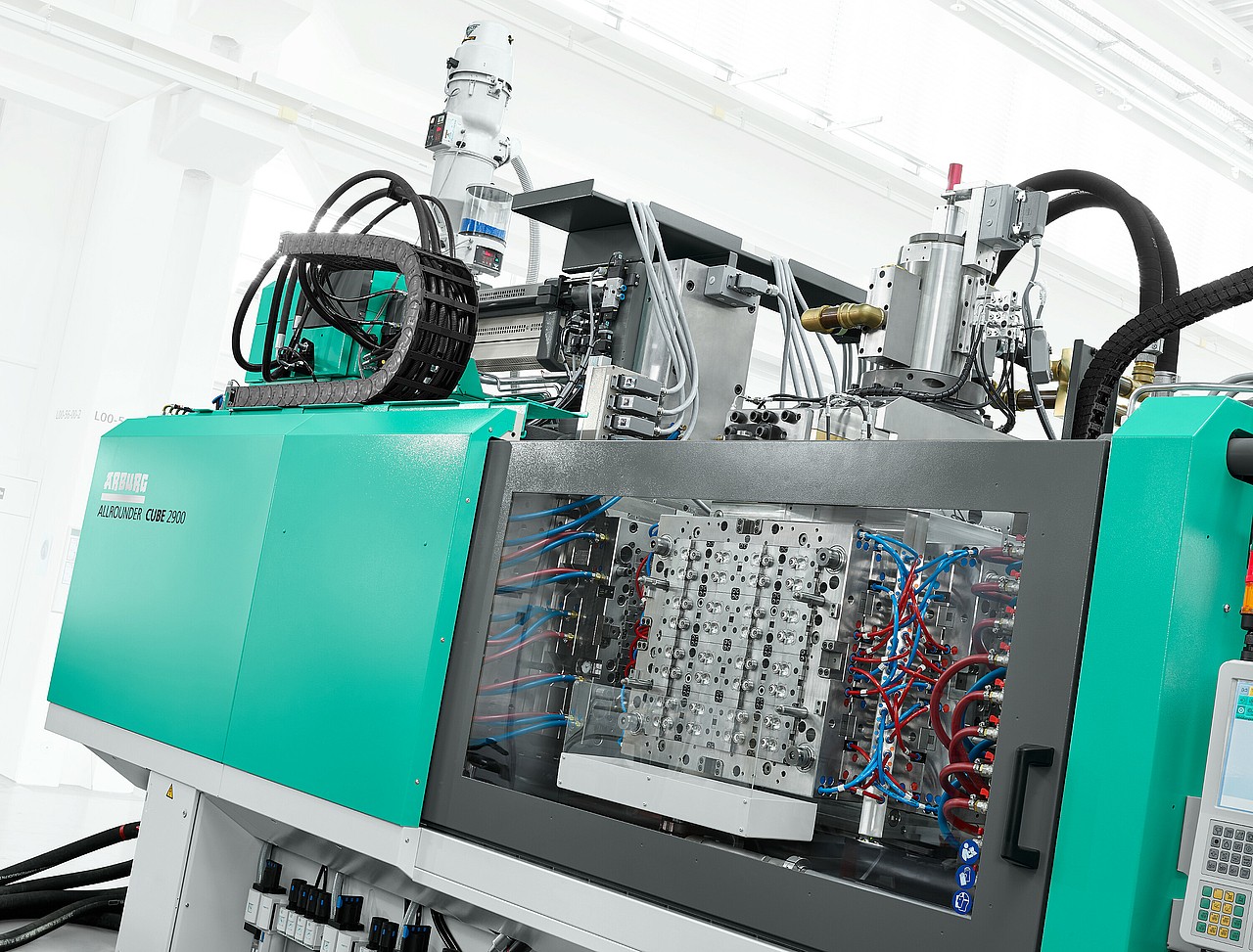

Efficiency for high-volume production: An ALLROUNDER CUBE cube machine with high-speed servo-electric toggle-type clamping unit produces 13,000 parts per hour.

32-cavity

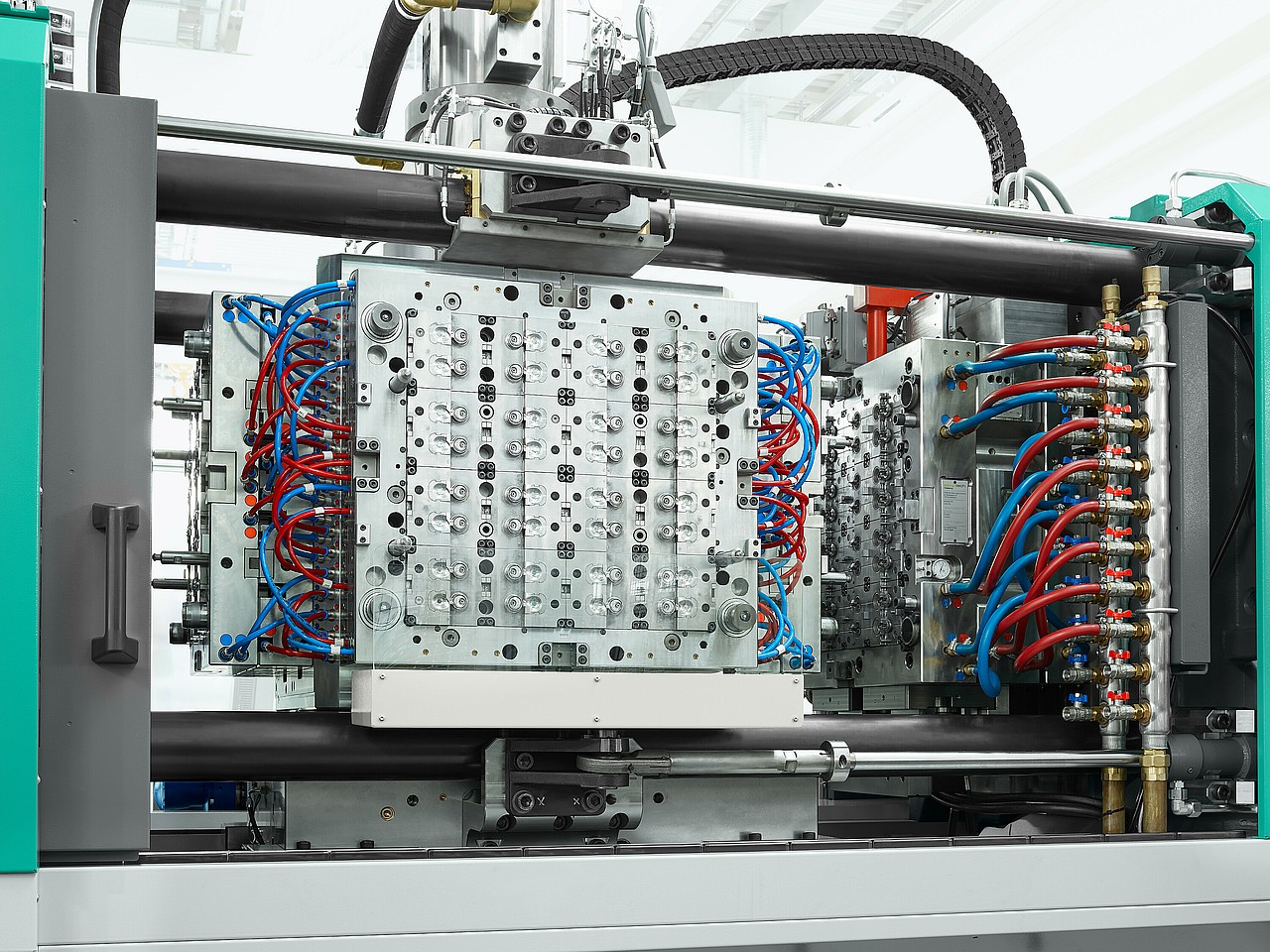

Together with its partner Foboha, ARBURG implements complete cube systems, e.g. for 32-cavity moulds with servo-electric cube turning and independent displacement axes.

Process-optimised

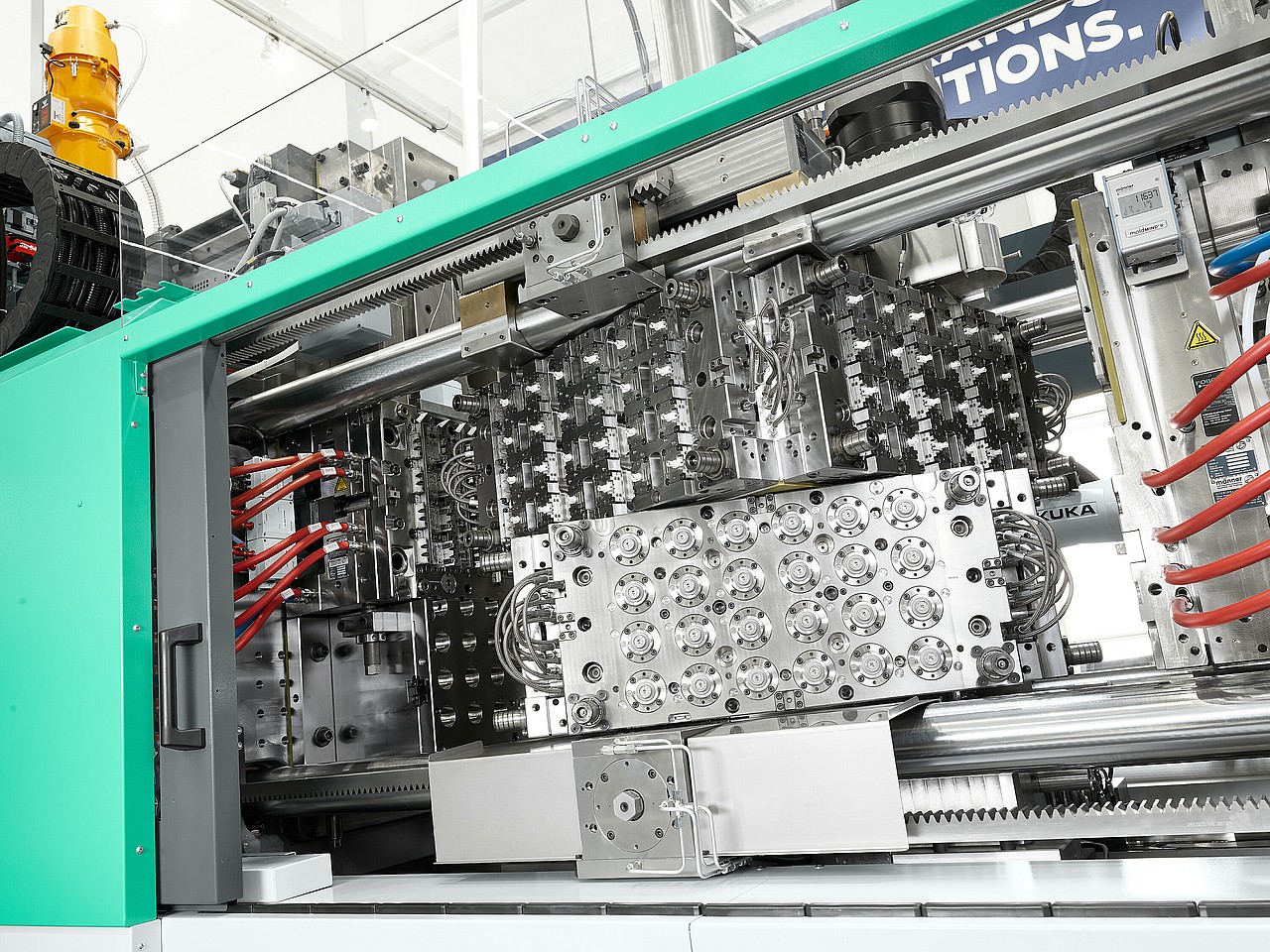

The mould is integrated into the SELOGICA control system. This allows free programming of all tool functions.

Cube-mould technology for two-colour flip-top closures

ARBURG solutions used

ALLROUNDER CUBE 2900

In the ALLROUNDER CUBE 2900 cube machine with a clamping force of 2,900 kN, the servo-electric toggle-type clamping unit and servo-electric cube turning enable fast cycles with reduced energy requirements.

Injection units

For injection moulding of the two different coloured PP components, two independently moving injection units are arranged horizontally and travelling above the mould mounting platen.

Cube mould technology

With the four cube sides that can be used for production, mould filling, cooling and part removal run simultaneously. In addition, twice the number of cavities are available with the same mould mounting surface.

Turnkey solution

ARBURG implements complete cube systems for the packaging industry with its partner Foboha. The modularity of the CUBE series and the "smart" control system enable precise matching to the mould technology.