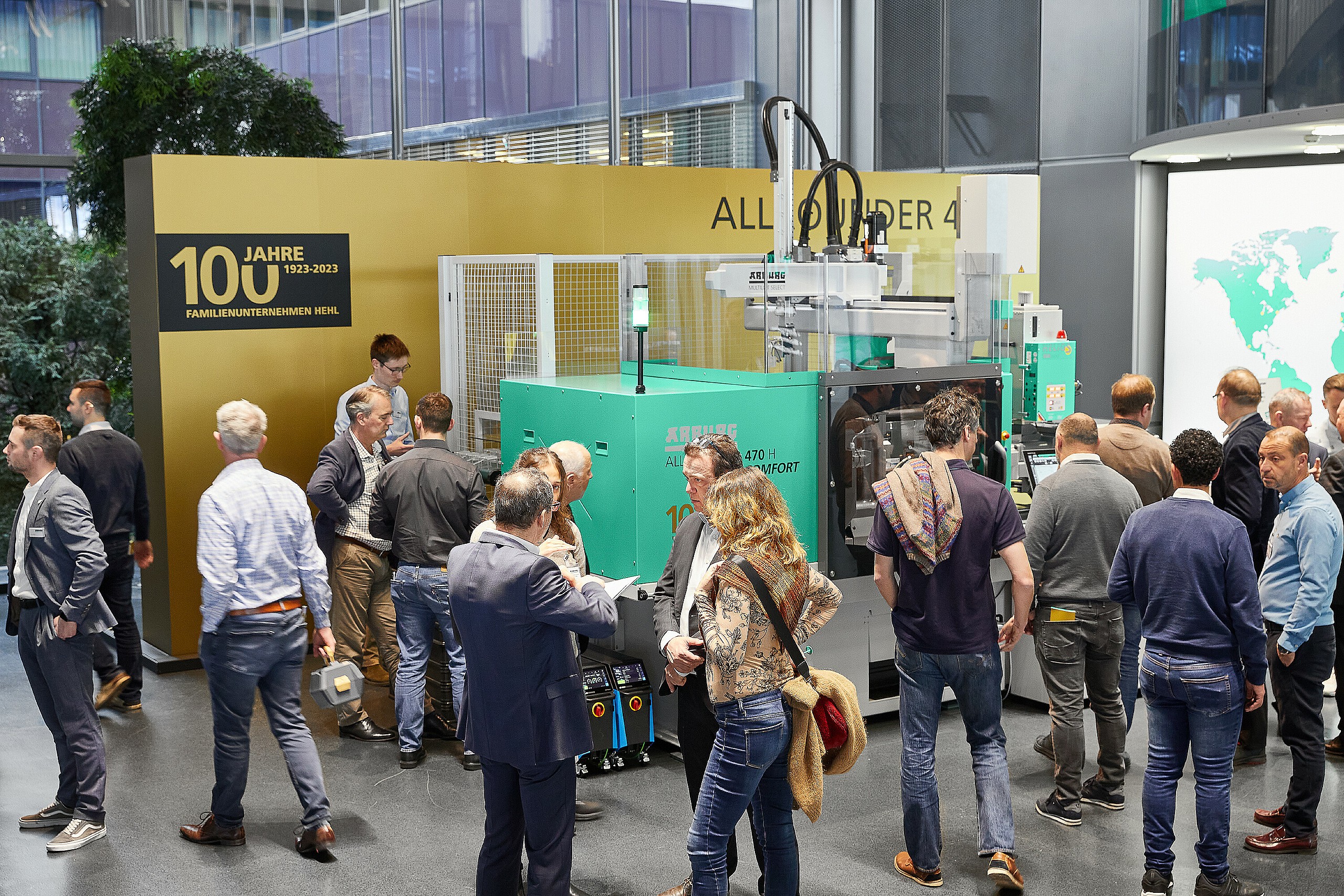

New ALLROUNDER 470 H

The new ALLROUNDER 470 H, which the company has launched to mark its special anniversary: "100 years of the Hehl family company", will be on show for the first time at Plastpol. The exhibit will be producing coffee cups with a lid, which will be filled with sweets using a simple automated mechanism on the machine – making them an ideal trade fair give-away.

To news about the anniversary machine