Energy-efficient: New ALLROUNDER GOLDEN EDITION ASH

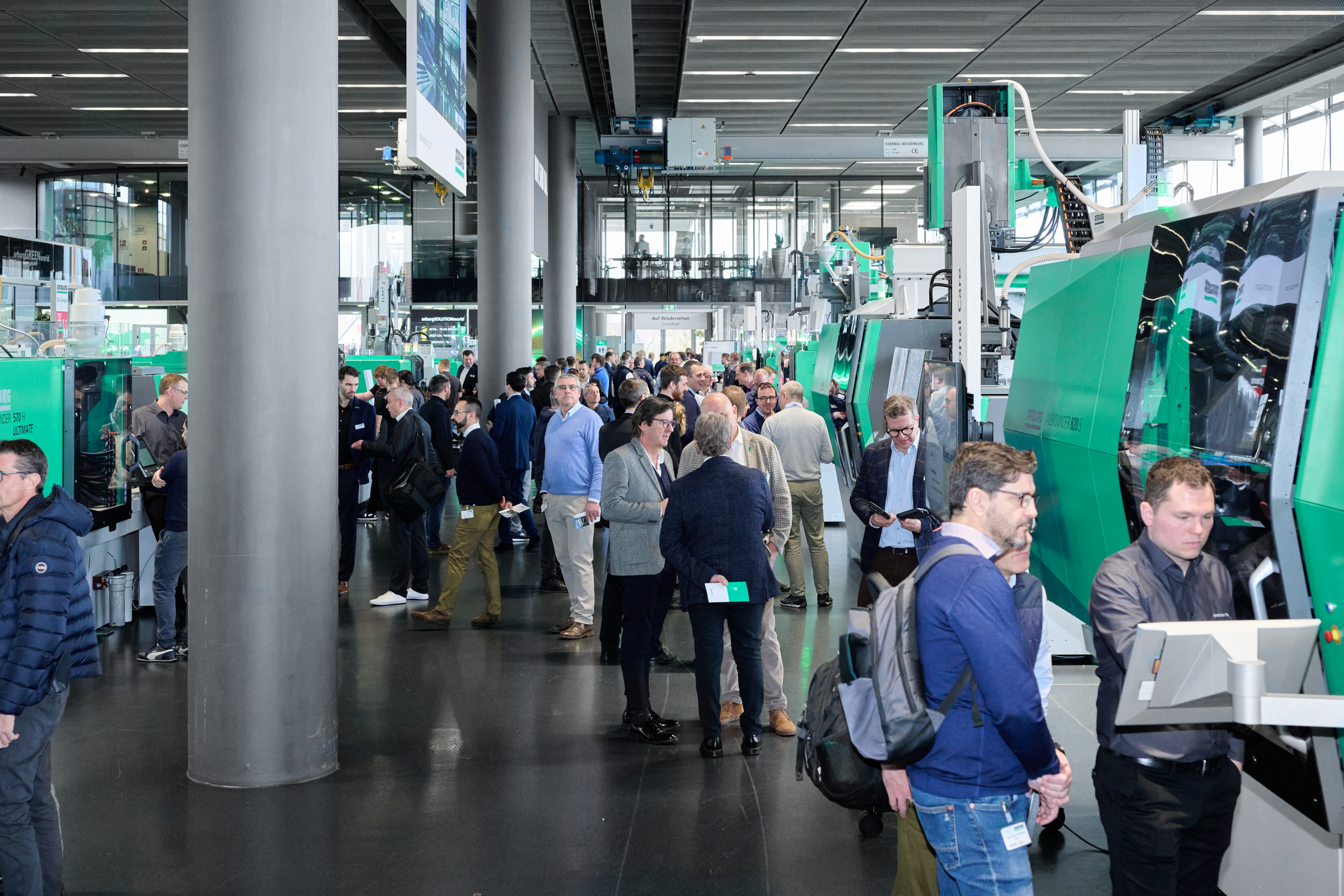

Anyone looking for an entry-level hydraulic machine with an extremely attractive price/performance ratio, proven high performance and significantly reduced energy requirements will be surprised by an interesting innovation: with immediate effect, all hydraulic ALLROUNDER GOLDEN EDITION machines in sizes 420 to 570 are optionally available with dual-circuit pump technology with ARBURG servo-hydraulics (ASH). Thanks to energy-optimised and speed-controlled servomotors, the specific energy requirement can be reduced by up to 50 percent depending on the process.