Benefits at a glance

Clear

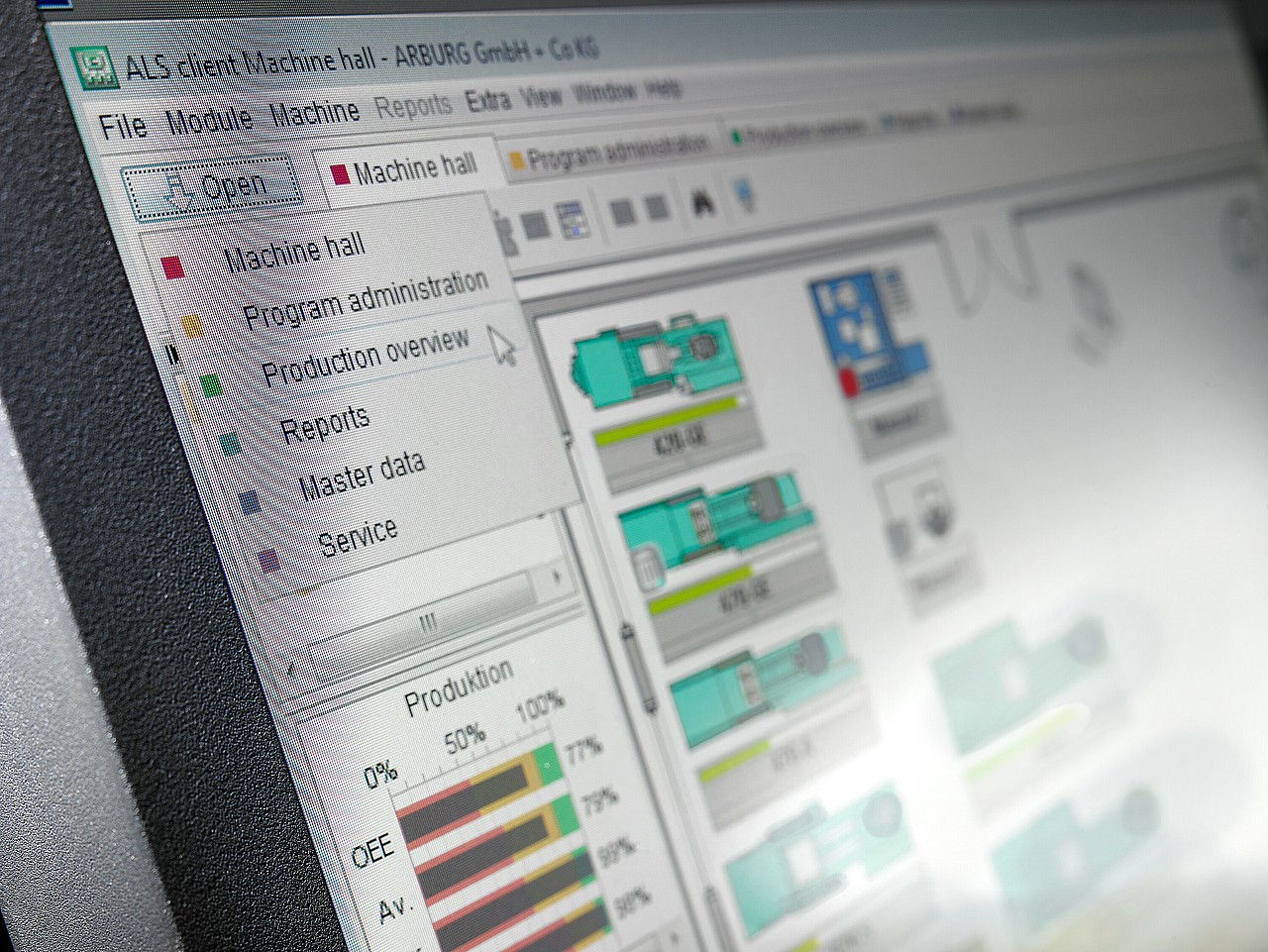

Want to track job progress, machine statuses, process parameters and alarms at a glance? ALS displays all relevant production data in a clear and coordinated manner.

Optimised

If things get too complex for ERP, PPC or PDA control stations: ALS is tailor-made for injection moulding production. Allowing you to optimise capacity utilisation, quality and delivery reliability.

Traceable

ALS documents all relevant information in a permanent and traceable manner. With indicators and statistics. With no manual data acquisition. Always up to date.

Comprehensive

Process data is recorded online, clearly prepared and available across the board – even across several locations and to higher-level PPC and ERP systems.

Explainer video: ARBURG host computer system

Areas of application

Detailed planning

ALS already takes into account the storage location and availability of injection moulds including inserts and accessories when planning jobs. Configuration data is transferred online to the machine. For efficient operational sequences.

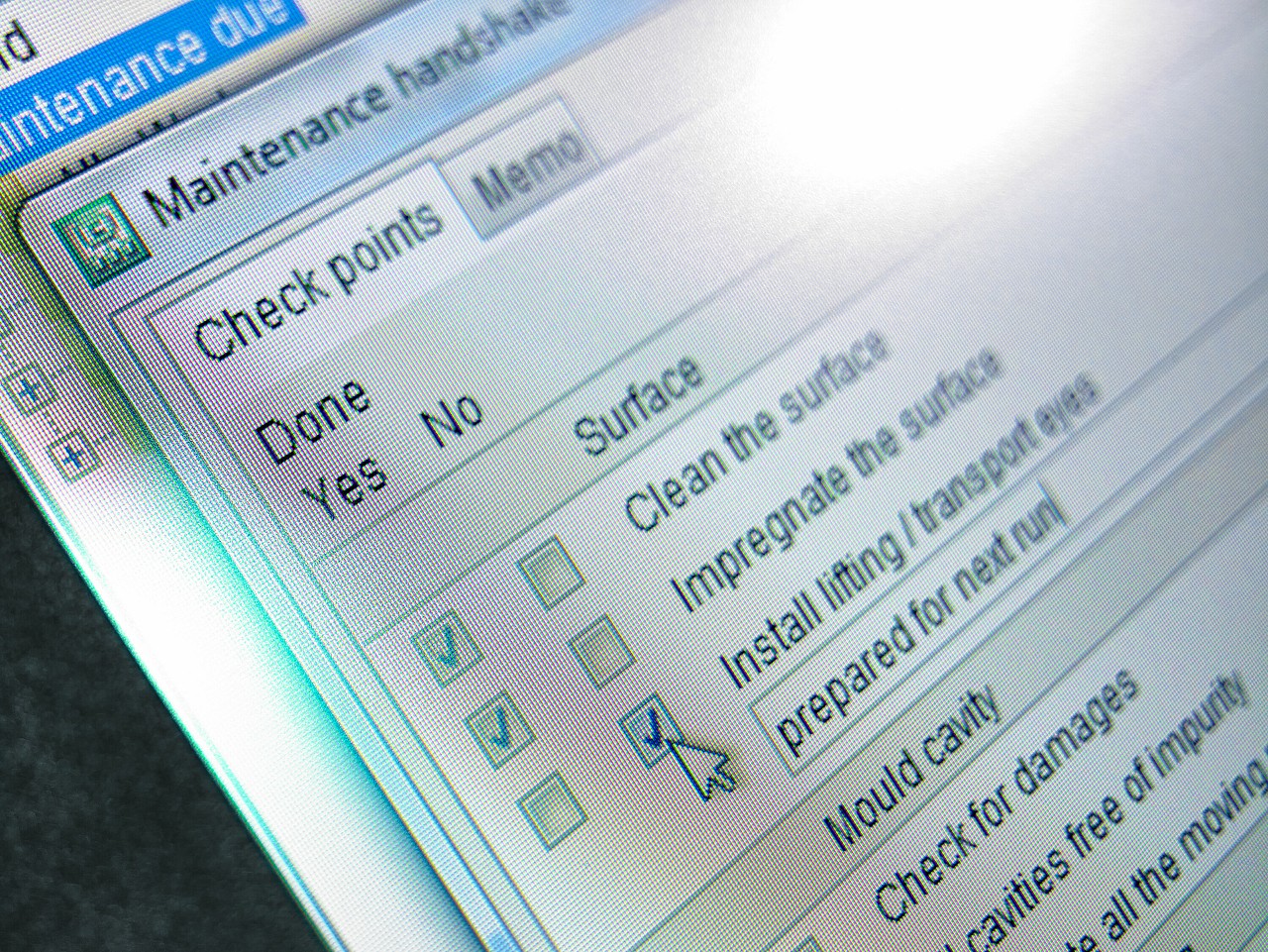

Maintenance

ALS documents the life cycle of all the equipment. Shot counts, operating hours, set-up processes etc. are automatically determined. Maintenance work can be reliably carried out and documented thanks to interactive check lists.

Documentation

For job planning, you can use ALS to define combinations of machine, peripheral equipment, mould and material, for example, for which there is a single validated data set. This enables GMP-compliant documentation.

ALS Support

Contact

Tel.: +49 (0) 7446 33-3401

ALS_support_germany@arburg.com

This might also be of interest

Are you looking for traceability, production on demand, and circular economy? Then our arburgXworld customer portal offers you unique digital added value.

Make use of synergies for your operations with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.

Make optimum use of resources and reduce unit costs: Our solutions enable you to achieve maximum productivity with minimum operating costs, resulting in high cost-effectiveness.