Finishing

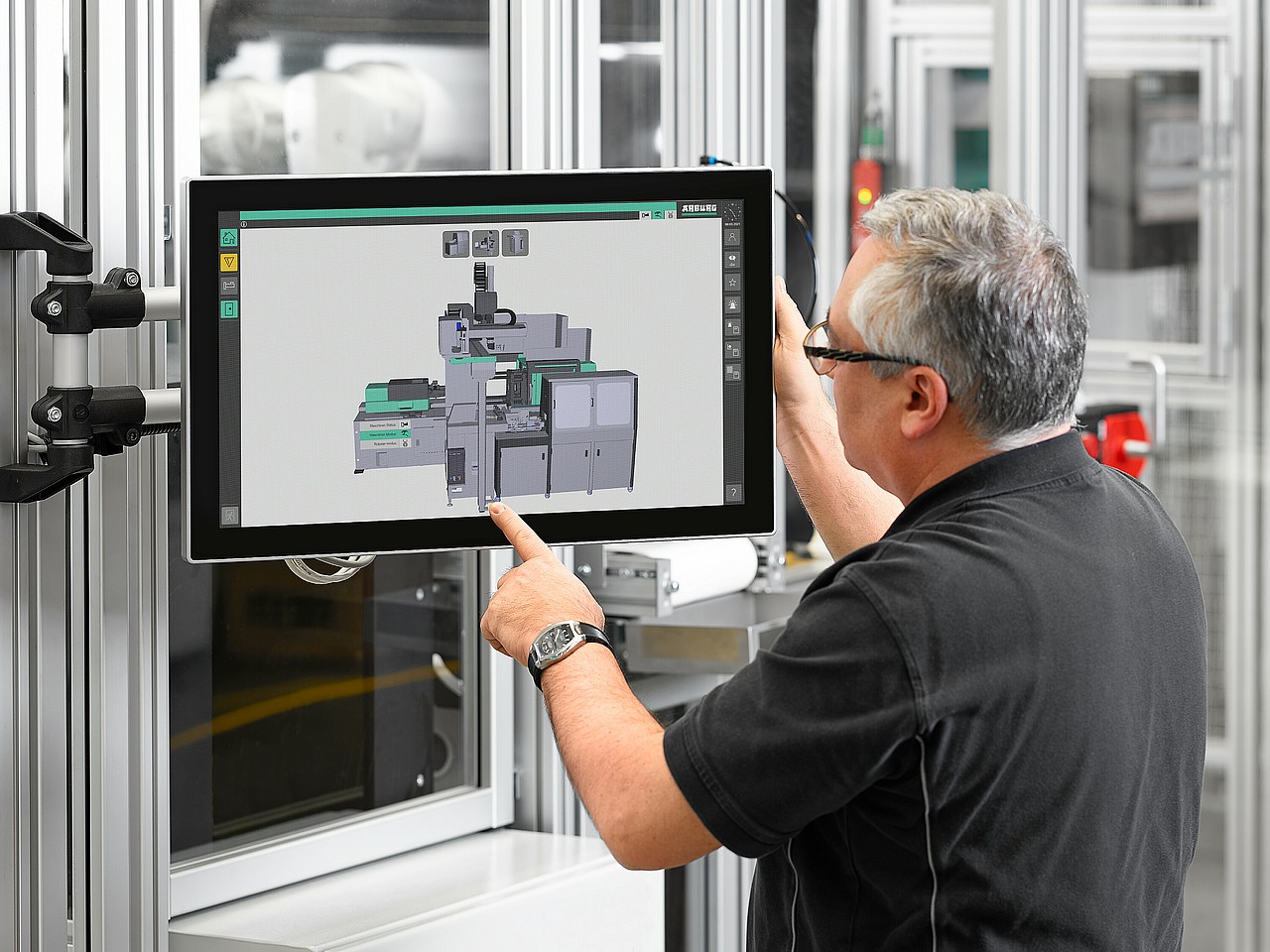

Various image motifs can be selected via a tablet at the production cell and the cups can then be finished inline.

Seamless

The ARBURG Turnkey Control Module (ATCM) collects all process and recycling-relevant data on a part-specific basis and enables seamless traceability.

Separation by type

Each cup receives a digital product passport, which can be used to call up important data for specific parts at any time.

R-Cycle: drinking cup with digital product passport

ARBURG solutions used

ALLROUNDER 370 A

An electric ALLROUNDER 370 A connected via OPC UA produces drinking cups from chemically recycled PP in a cycle time of 40 s. .

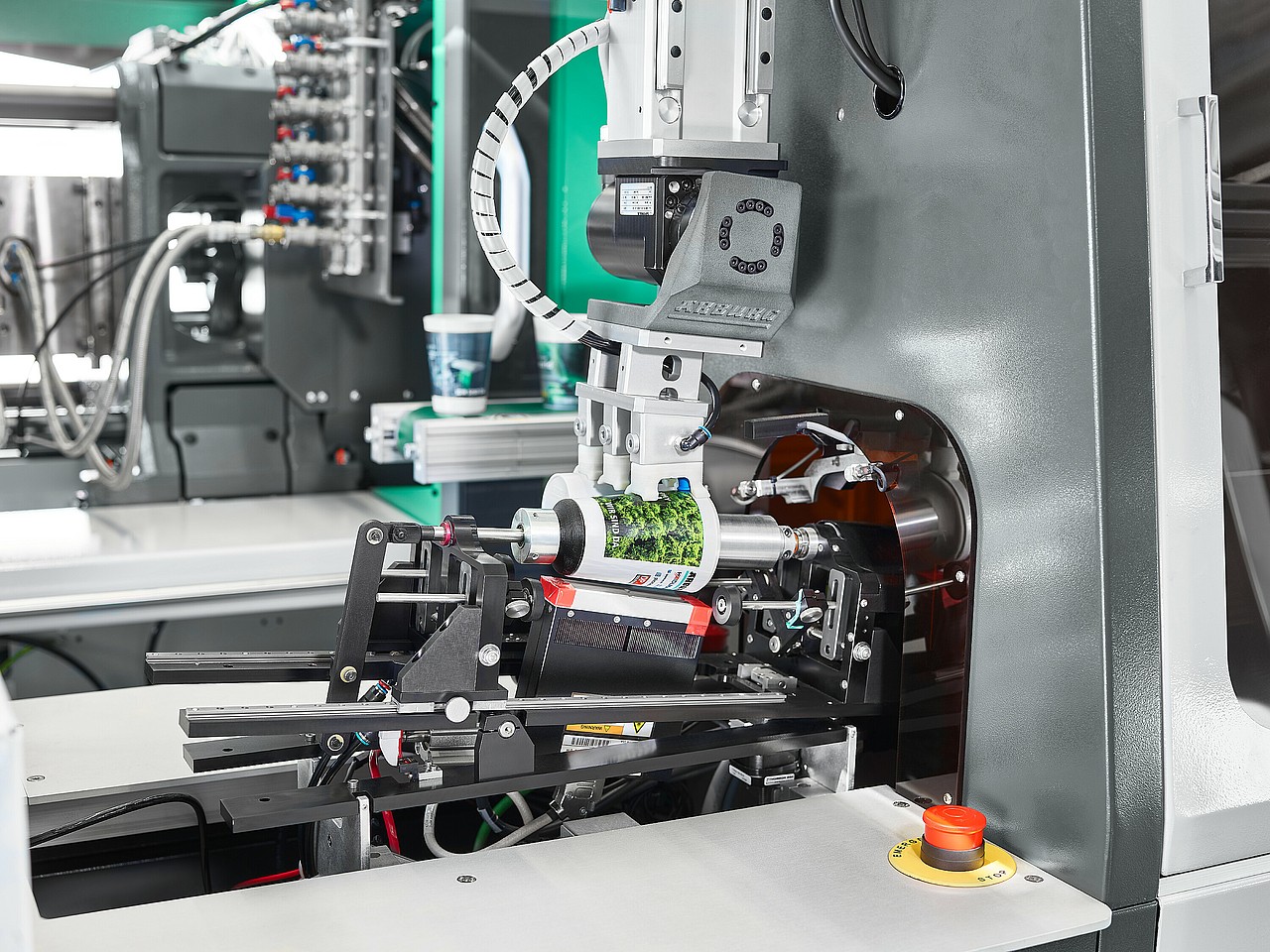

MULTILIFT V 20

Handling is performed by a MULTILIFT V 20. It removes the cup from the mould, feeds it to a plasma treatment and then to a digital printing station. This means that the product enhancement stage is integrated directly into the production cell.

SCADA-System ATCM

The ARBURG Turnkey Control Module (ATCM) collects all data in real time and consolidates it on a part-specific basis. Each product receives an ID code and an R-cycle code. This allows the cups to be traced and provided with a digital product passport.

Turnkey system

The "smart" manufacturing cell also includes the ATCM SCADA system, plasma finishing and digital printing. Image motifs can be chosen individually. The turnkey plant can be connected to an MES or ERP system via the IIoT gateway.