ARBURG helps customer modernise and retain all its tooling

Sponsored by Interplas, the award recognises important collaborations and teamwork between a moulding company and their machinery, tooling or technical solutions supplier. ARBURG and Panorama beat off healthy competition across the industry to secure the title for the fifth time.

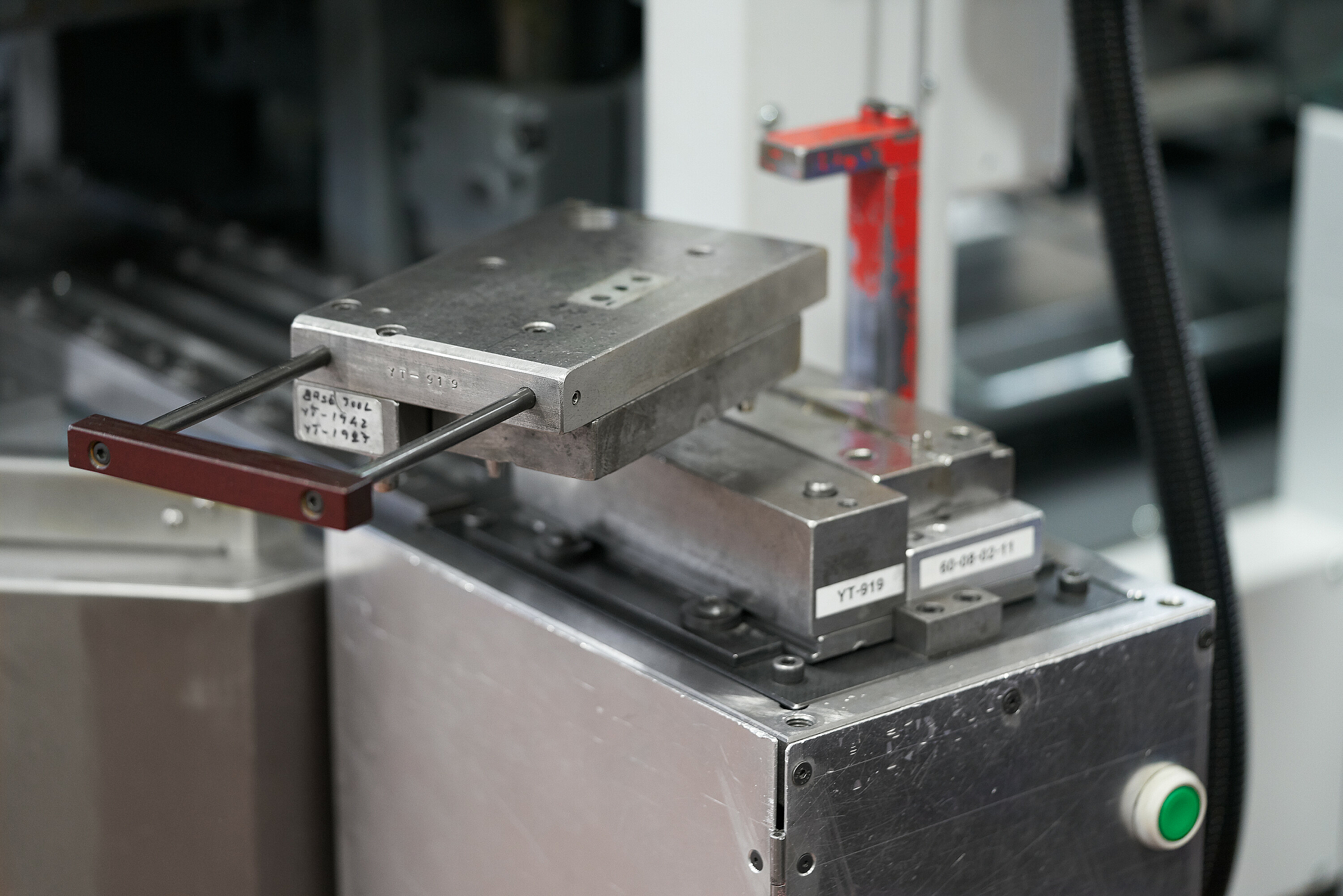

ARBURG supported London-based Panorama Antennas with a demanding technical project spanning several months to migrate their moulding capability from an old Manumold machine, which could no longer offer parts and support, to a new ARBURG 275 V 250-100 while retaining the ability to accommodate all Panorama’s existing tools – more than 50 sets of tooling, making retooling for the new machine financially unviable.

The company was committed to replacing its old machine (Manumold Ltd. had discontinued trading) but needed several very specific requirements, over and above a straight machine replacement, which included an “ex-machine” loading and unloading system that could not be done inside the ARBURG machine. The needs included:

- The split line injection position – horizontal injection at a given height

- The need to use all Panorama’s existing tooling without alteration

- Loading and unloading of the tool into the moulding area

- Location of the tool when loaded needed to be 100% in-line with the injection position

- The split line position in relation to the handle for loading

- The new machine must comply with health and safety requirements, and

- Location and control of the ejector station

ARBURG engaged with the customer quickly and sought to engineer practical and effective solutions to this full list. Following several weeks of meetings with ARBURG in Warwick and Germany, a loading/unloading solution was designed and Panorama manufactured the tool slide and ejector station, needing guidance as to what was required to deliver the solution with the ARBURG machine.