Additive manufacturing of end-of-arm tooling (EOAT)

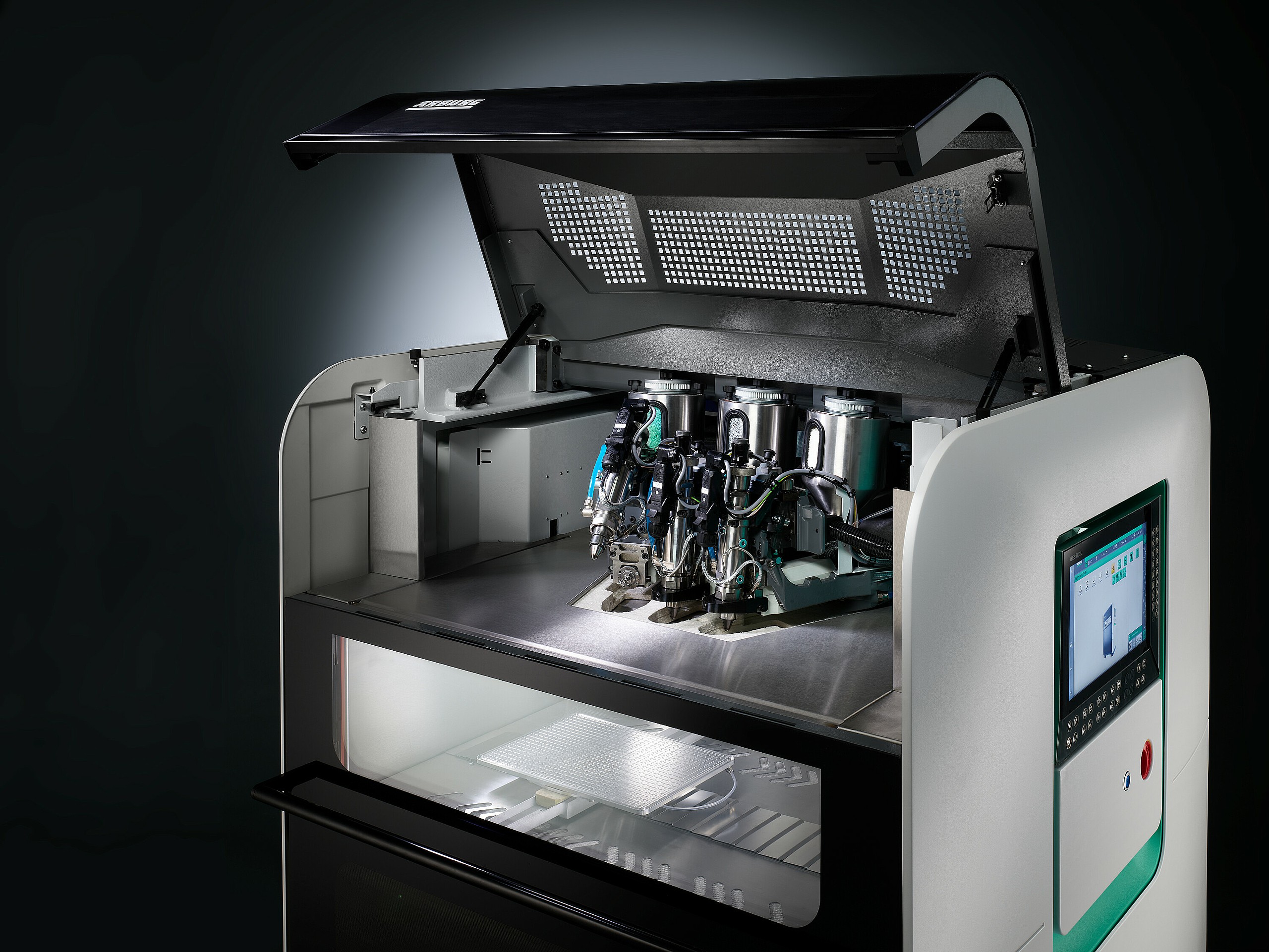

At Chinaplas 2024, a freeformer 300-3X will demonstrate how additive end-of-arm tooling (EOAT) for various robotic systems and handling tasks can be 3D printed on demand quickly, cost-effectively and customised for specific applications. One example is a multi-material gripper, which is created in a single step with the aid of support material and without the need for any additional assembly work. The result is a resilient functional component in hard/soft combination. The hard housing is made of PC/ABS, while the soft TPE nozzle closure expands positively using compressed air to reliably remove a moulded part from the mould.