Cost-effective

The MuCell® and chemical foaming processes are combined for stable, fast and cost-effective series production.

Reusable

The thermal cups can be used hundreds of times and are even lighter than the common disposable paper alternatives.

Customisable

The product can be customised with any design via in-mould labelling (IML) if desired.

Insulating: foamed reusable cups

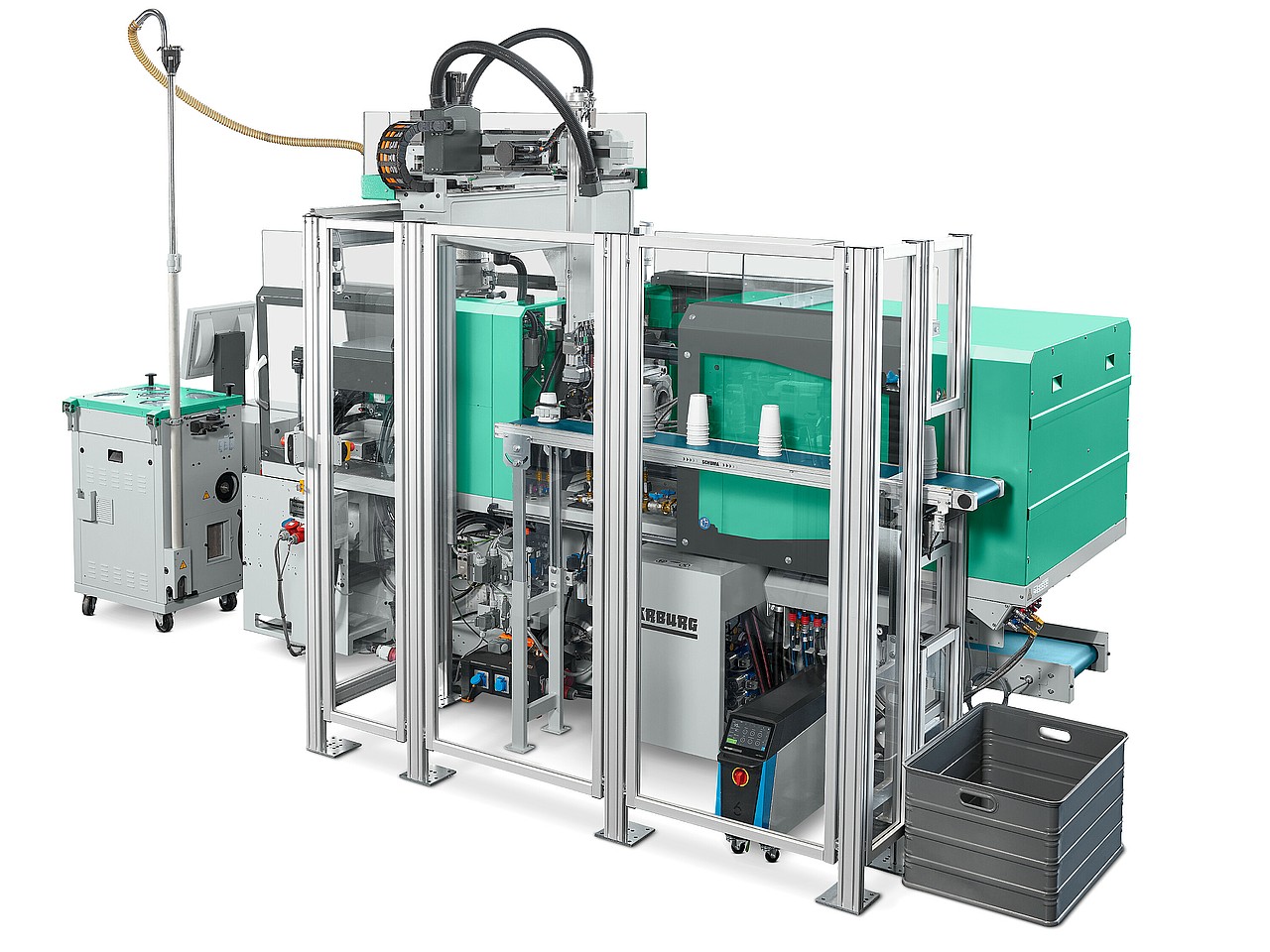

ALLROUNDER 470 S

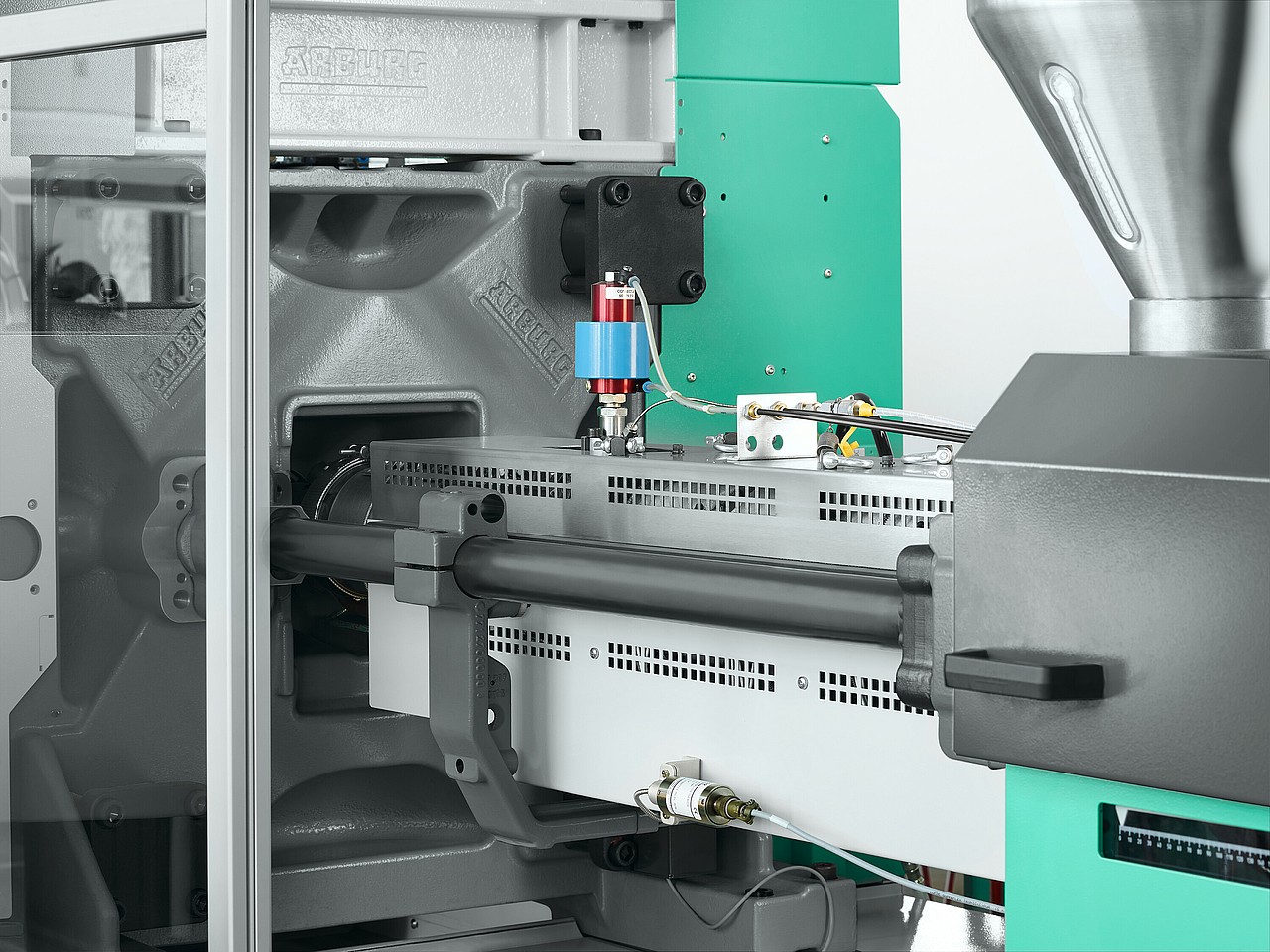

The cups can be produced on a hydraulic ALLROUNDER 470 S, for example. After injection, the 1-cavity mould opens and the component foams up. The wall thickness is then 2 mm.

MULTILIFT SELECT

To ensure that the MULTILIFT SELECT can remove the cups particularly gently, it is equipped with a matching gripper. This was additively manufactured by a freeformer especially for this purpose.

MuCell® process

With MuCell®, the material is enriched both chemically with a blowing agent and physically with gas. The skin-foam-skin structure with fine-cell foam cells ensures low weight, great strength and thermal insulation.

Turnkey system

In addition to efficient machine technology, ARBURG offers individual turnkey solutions. The production cell for manufacturing the thermal cups can optionally be supplemented with an IML system.