Benefits at a glance

No limits

With ALLROUNDERs, you can master any process and transform the most varied of materials into resilient components for interiors, exteriors and engine compartments.

Tailor-made

We configure your injection moulding machines precisely to your requirements. So you can process thermoplastics, thermosets, elastomers and liquid silicones with ease.

Innovative

Technical parts, textured parts, optical parts: Use innovative processes for the mobile sector such as fibre direct compounding and film technology.

Flawless

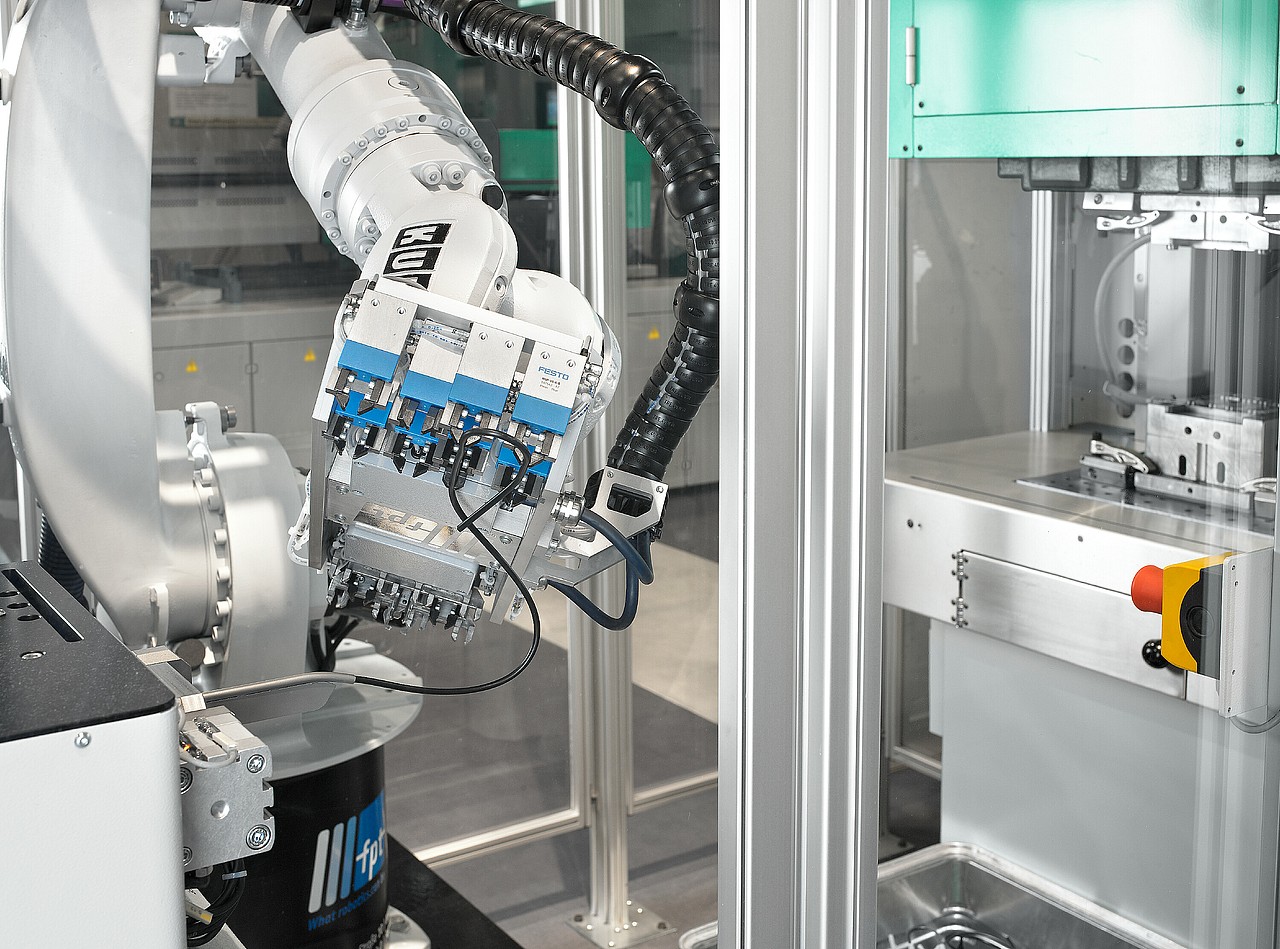

Precise, small, resilient, sophisticated – but are your products flawless too? Yes! Automated production cells also integrate upstream and downstream steps.

Example electromobility

Charge-Port

Charge-Port

Charging electric vehicles: ARBURG machines produce components for wall boxes as well as for the charge port on passenger cars.

Ventilation components

Ventilation components

Ventilation nozzles with adjusting brakes are used for car air conditioning. Such hard-soft components (e.g. PBT and LSR) can be mass-produced on a multi-component ALLROUNDER.

Rear-view mirror unit

Rear-view mirror unit

Rear-view mirror units contain numerous components made of plastic. By means of LSR coupling pads, rain/light sensors can be optimally connected to the windscreen.

Headlights

Headlights

The injection-compression moulding process is predestined for LED attachment lenses. By linking injection moulding and foaming, sealed housings for car headlights can be produced.

Sample components

FDC housings

Cable drive housings made from PP with 30% long glass fibres (incinerated on the left) produced in the FDC process have a resilience similar to that of parts made from PBT and are also 30% lighter.

icam connector

icams assist with parking. A secure connection between the camera and the electronics is ensured by eight-pin connectors with seals, manufactured on a two-component rotary table machine – two million units per year.

Rain/light sensor

LSR compensates for curvature: a rain/light sensor can be perfectly connected to a car windscreen using a coupling cushion. The liquid silicone is injected onto a PBT frame into which the sensors are inserted.

This might also be of interest

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.

Save costs, increase efficiency and conserve resources with lightweight construction: Use innovative injection moulding processes such as fibre direct compounding (FDC) and physical foaming with MuCell®.

Increase added value, optimise the injection moulding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.