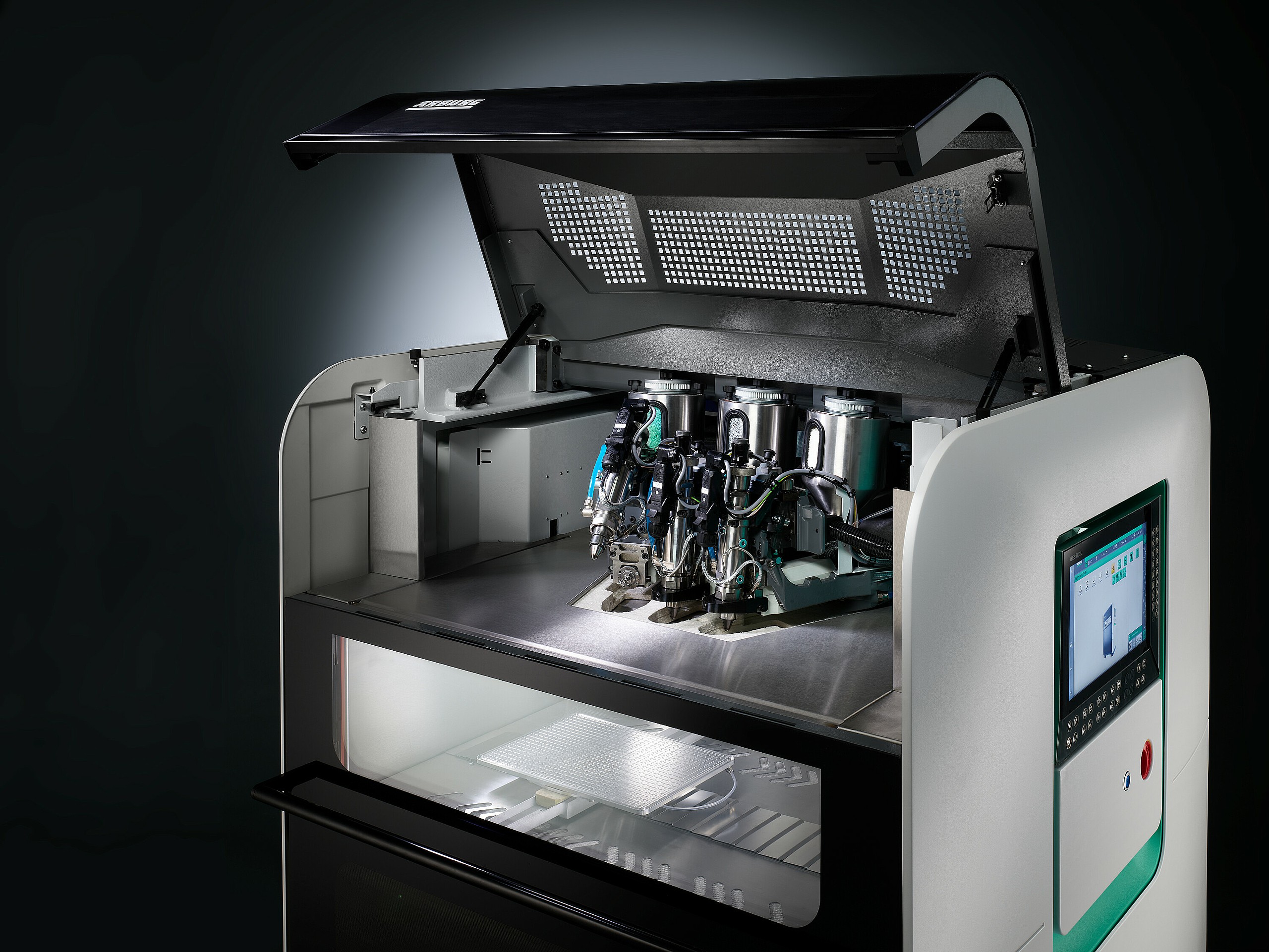

Processing of high-temperature plastics

At Fakuma, a new high-temperature version of the freeformer 750-3X will be producing geometrically sophisticated air distributors from original material Ultem 9085. To achieve this, the temperature of the build chamber can be raised to 200 degrees Celsius, and the granules are plasticised at up to 450 degrees Celsius. Many APF components will be on display at Fakuma, including orthopaedic insoles as two-component parts that can be individually adapted to the footbed.