Benefits at a glance

Elastic

From liquid or solid to highly elastic. With solutions from ARBURG, you can interlink LSR and HTV at high temperatures and achieve perfect silicone properties.

Neutral

Want to produce odourless and tasteless parts? Neatly finished and immaculate? Our ALLROUNDER injection moulding machines produce flawless silicone products.

Resistant

Abrasion resistant, UV and ageing resistant, heat resistant, electrically insulating, resistant to chemicals, sterilisable. Silicone injection moulding is the answer.

Controllable

Working with moulds hotter than 200 C and vulcanising LSR and HTV? If you mix liquid components homogeneously, tamp solid compounds correctly, work professionally: ARBURG.

Benefits of silicone injection moulding

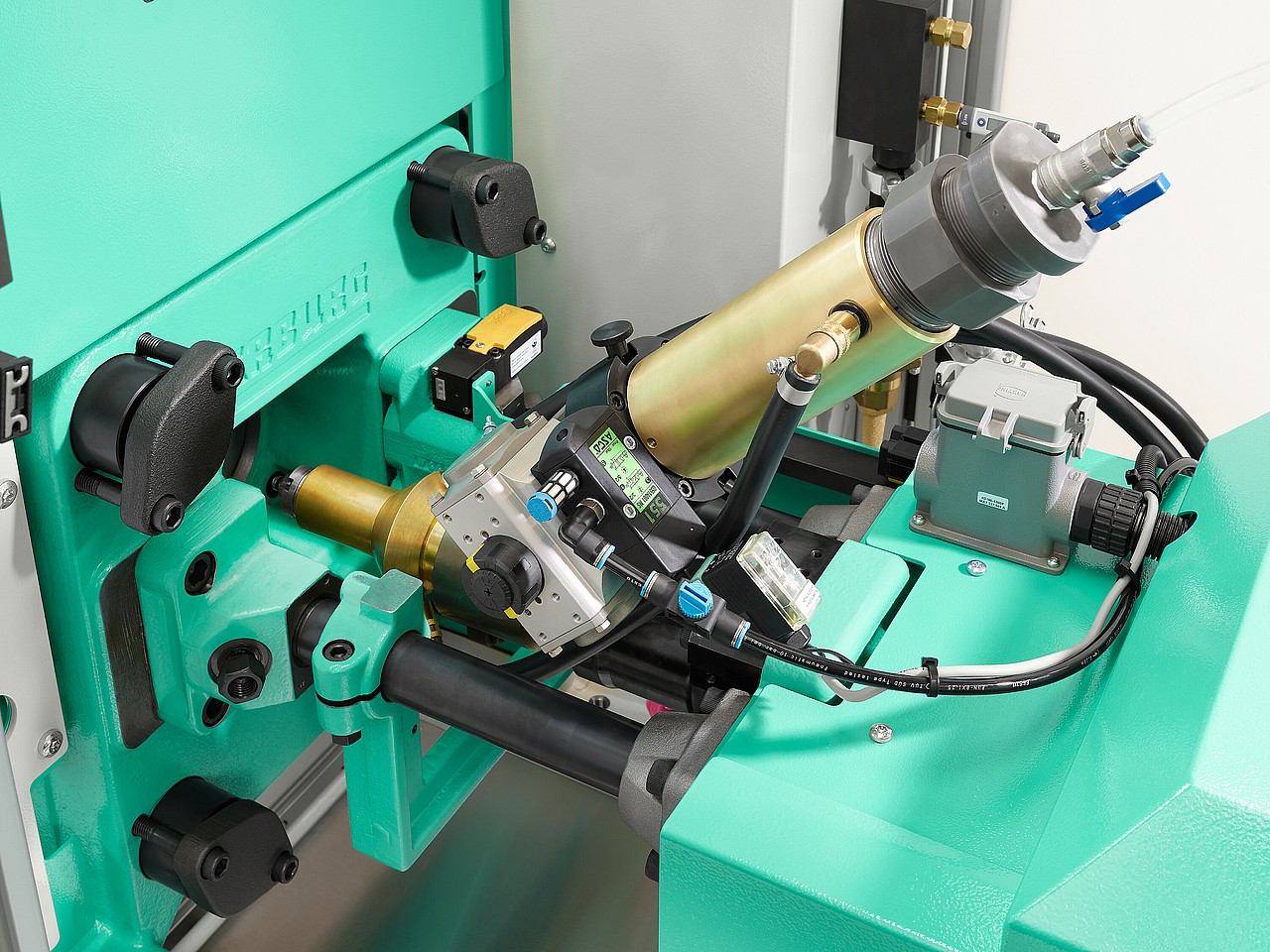

LSR non-return valve

LSR non-return valve

High processing quality, thanks in part to cylinder modules that have been precisely adapted or an LSR non-return valve that closes automatically.

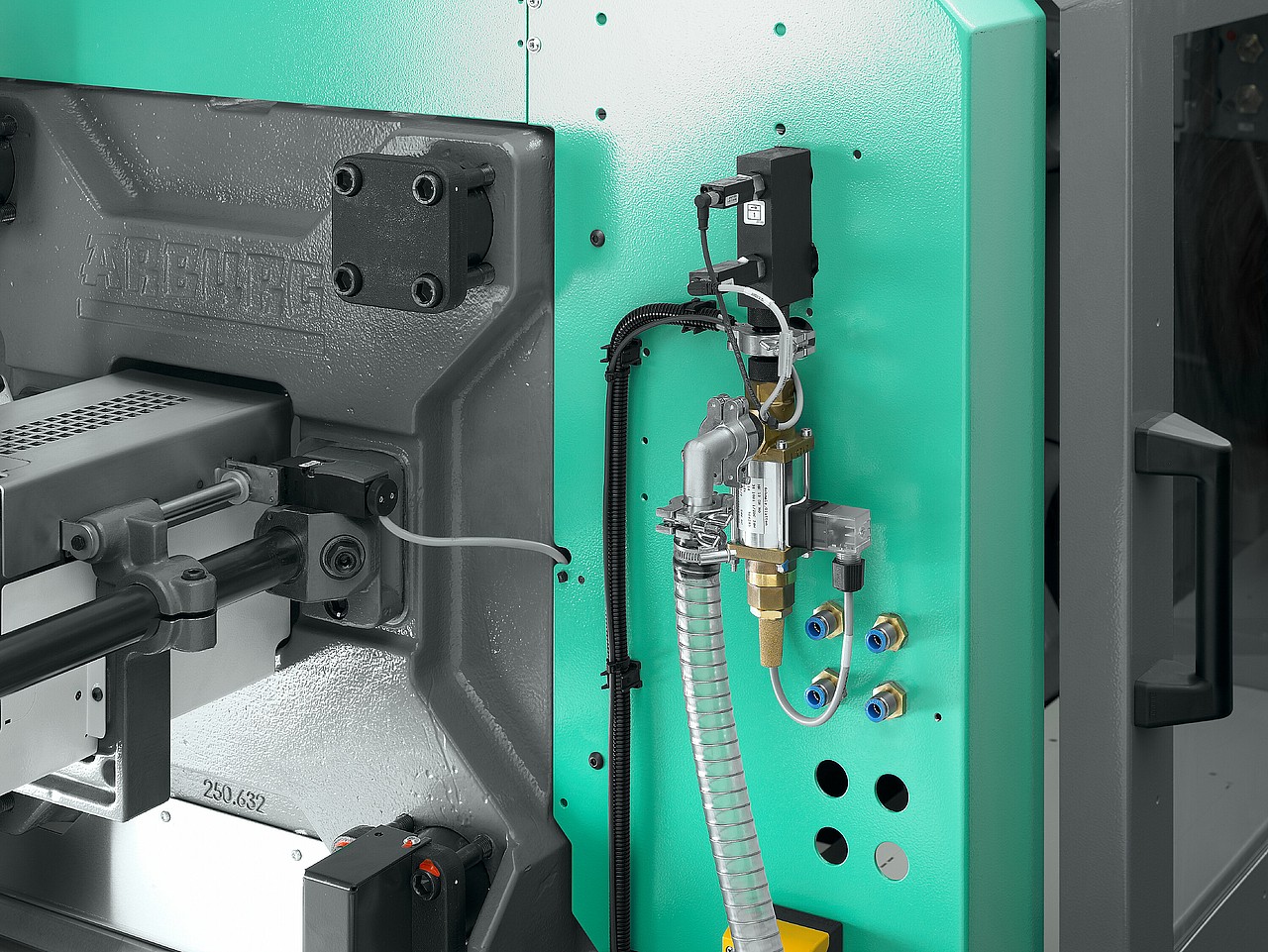

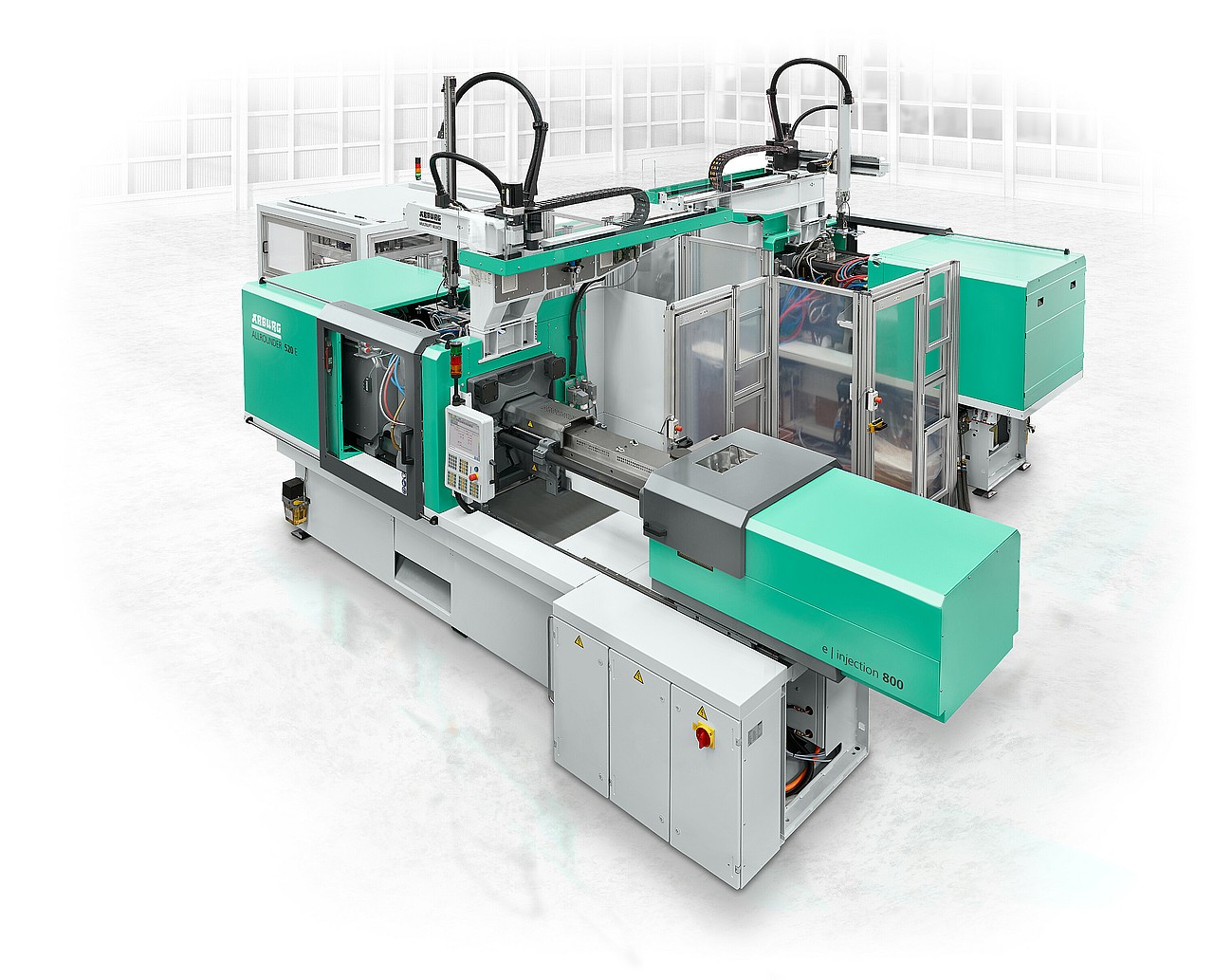

System solution

System solution

ARBURG offers individual system solutions for LSR and HTV – from an ALLROUNDER equipped for specific processes to a complex turnkey system.

Silicone package

Silicone package

As an option, you can use the ARBURG silicone package with OPC-UA for flexible process control between the ALLROUNDER and your production environment.

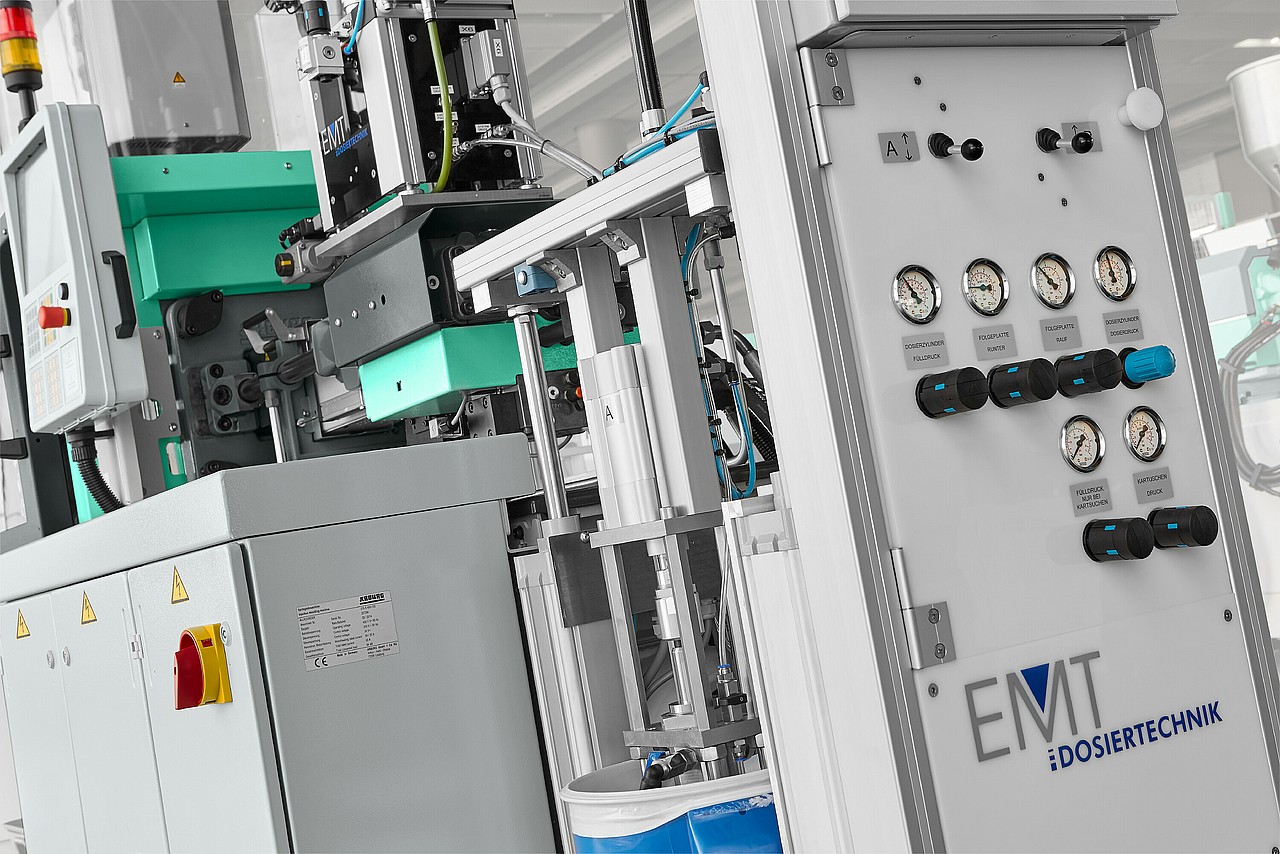

Dosing unit

Dosing unit

Pneumatic, hydraulic or servo-electric dosing units? For your complete solution, we work closely with leading industry manufacturers.

Sample components

2C push button

Twice as soft: the 2-component push-button combines the different properties of two silicones with different Shore hardnesses.

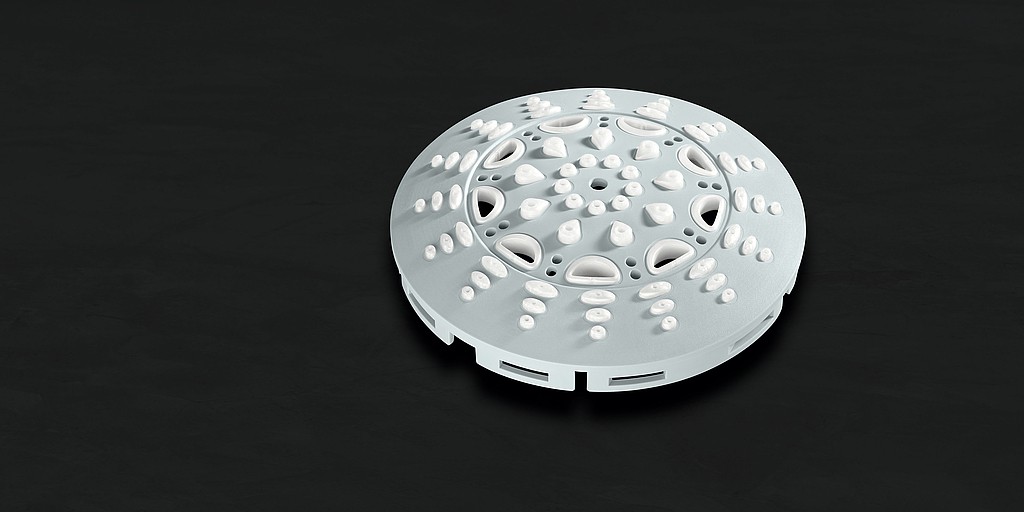

Flow straightener

A flow straightener made of PBT and LSR is produced for a shower valve with a 2+2-cavity mould. With hot runner technology for thermoplastic and cold runner technology for LSR.

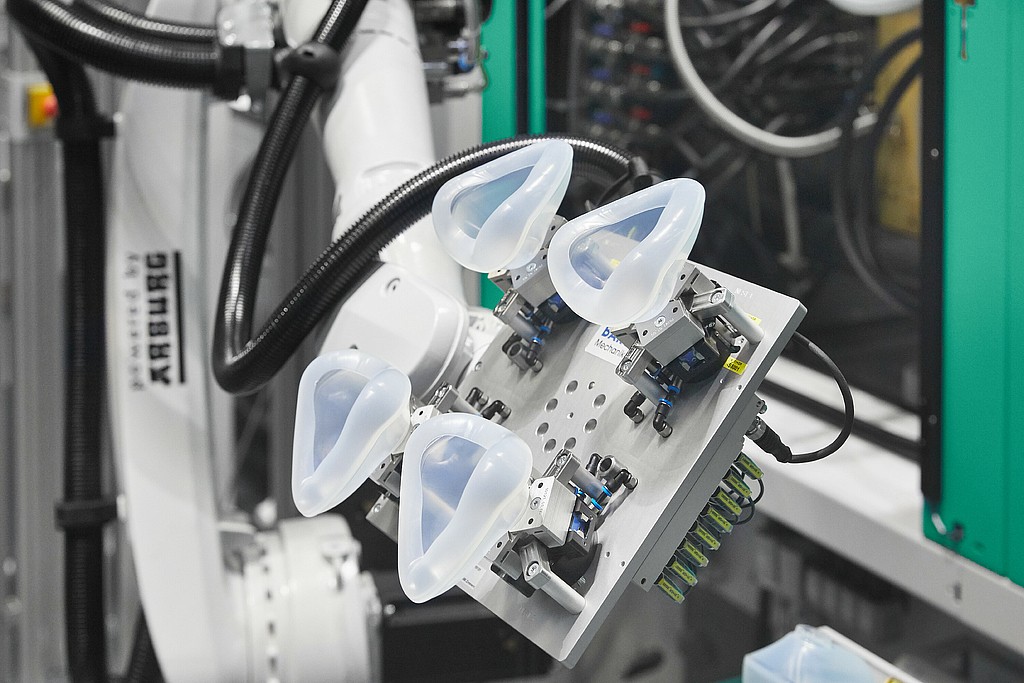

Mask

High quality face mask made of soft LSR and a solid PP shield. Four LSR masks are produced per cycle and removed by a six-axis robot.

Automated production cell

Want to increase added value, optimise the injection moulding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

This might also be of interest

Producing parts with high precision and in accordance with the most stringent functional and quality criteria – this is what our electric ALLROUNDER ALLDRIVE machines are designed to achieve.

What do you need for your multi-component technology? Very flexible configurations. This is exactly what our modular ALLROUNDERs are designed for.

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.