Benefits at a glance

High precision

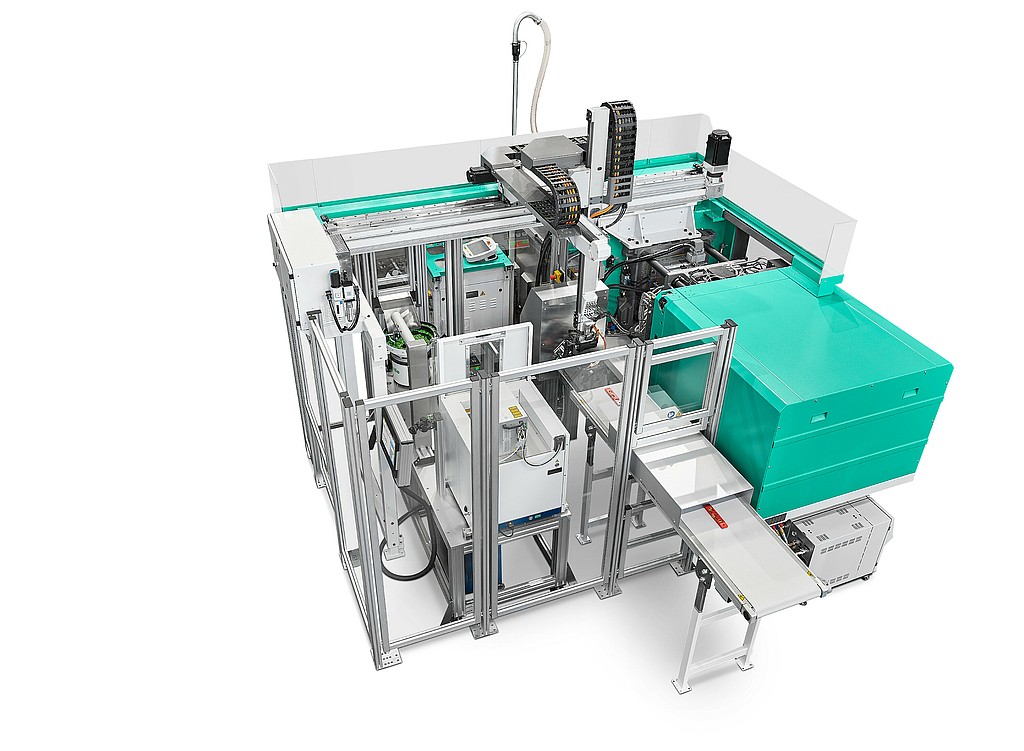

If medical technology, packaging or mobility are your business: with the ALLDRIVE, you bring an efficient and energy-saving electrical machine into your company.

High performance

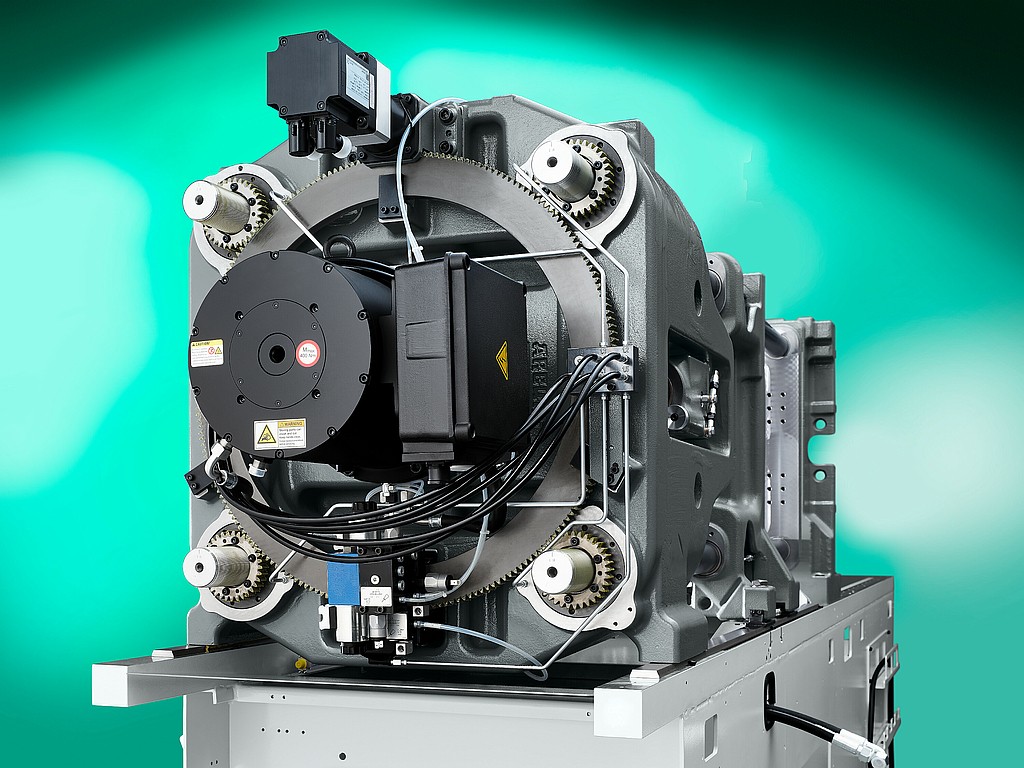

Powerful and efficient: that's our electric ALLDRIVE series. In various performance variants – precisely tailored to your individual needs. From one of the most comprehensive ranges in the industry.

Cost-efficient

Because you are counting: first choice for mass-produced articles because attractive quantities are possible thanks to short cycle times. You can count on ALLDRIVE ALLROUNDERs. Especially when it comes to demanding tasks.

Fast

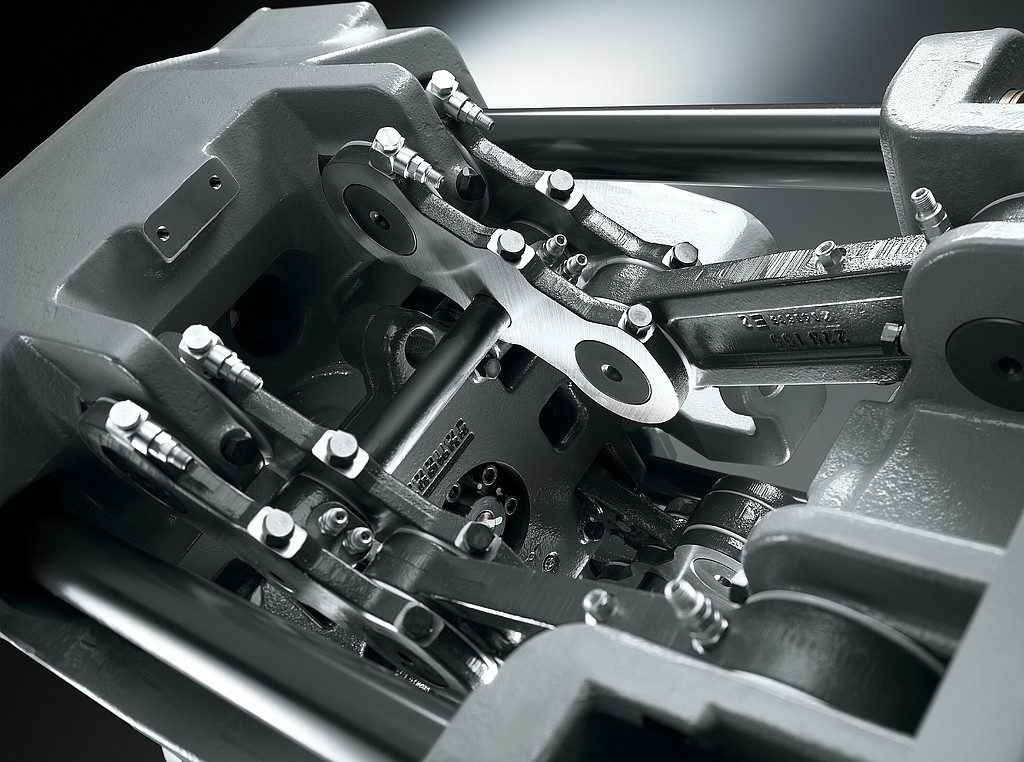

With your efficient ALLROUNDER ALLDRIVE, you save every day. And work in a highly cost-effective manner. With a kinematically coordinated toggle-type clamping unit. Extra fast thanks to simultaneous machine movements.

Technical data

Performance variants

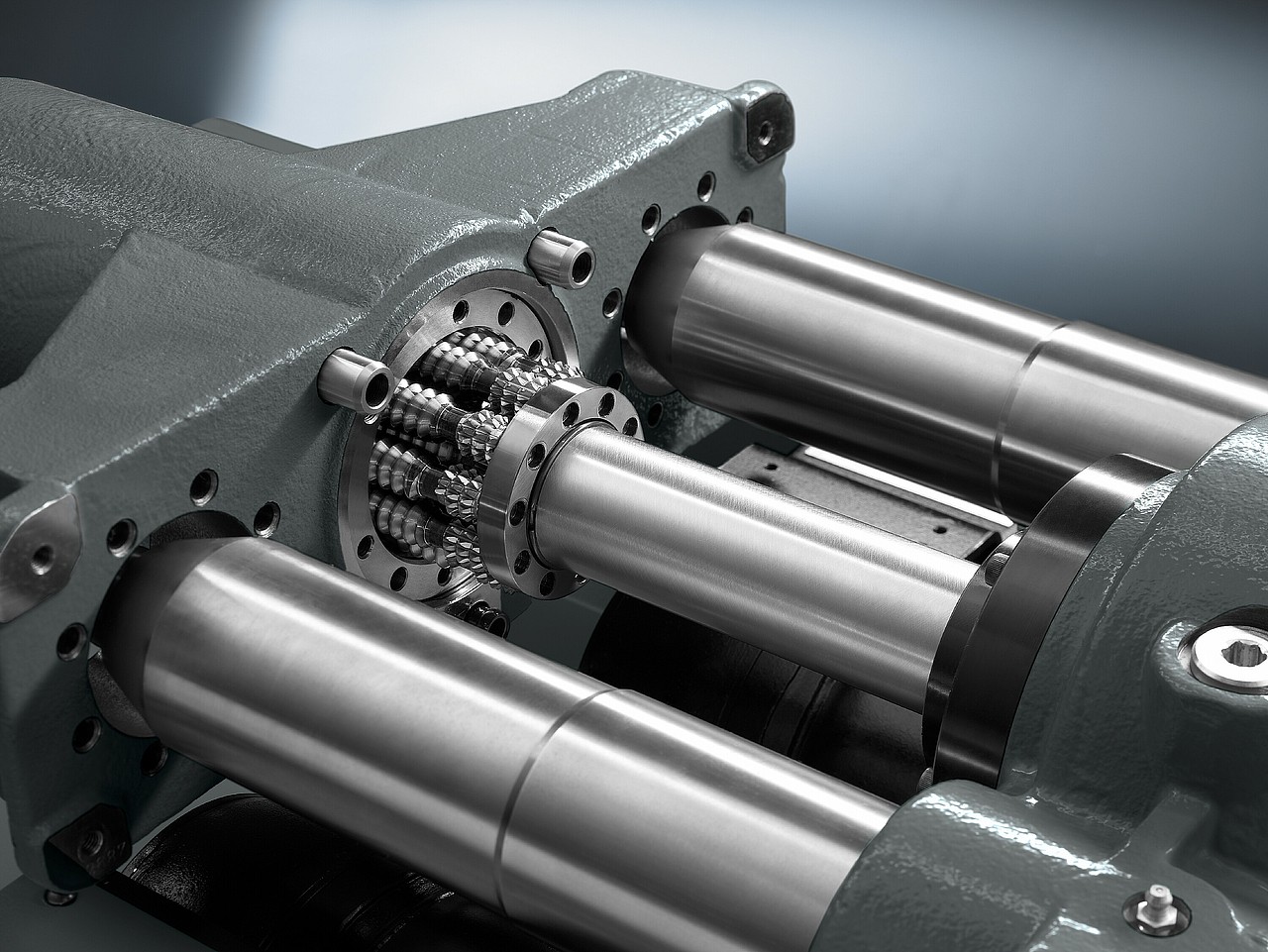

COMFORT | PREMIUM | ULTIMATE |

|---|---|---|

Performance specification comparable to standard hydraulic machines. | Version expanding on the COMFORT performance variant. | Version expanding on thPREMIUM performance variant. |

Ideally suited for technical parts | For a wide variety of applications | For high-speed and challenging processes |

Particularly energy-saving operation | Dry cycle times up to 15 per cent shorter | Dry cycle times up to 25 per cent shorter |

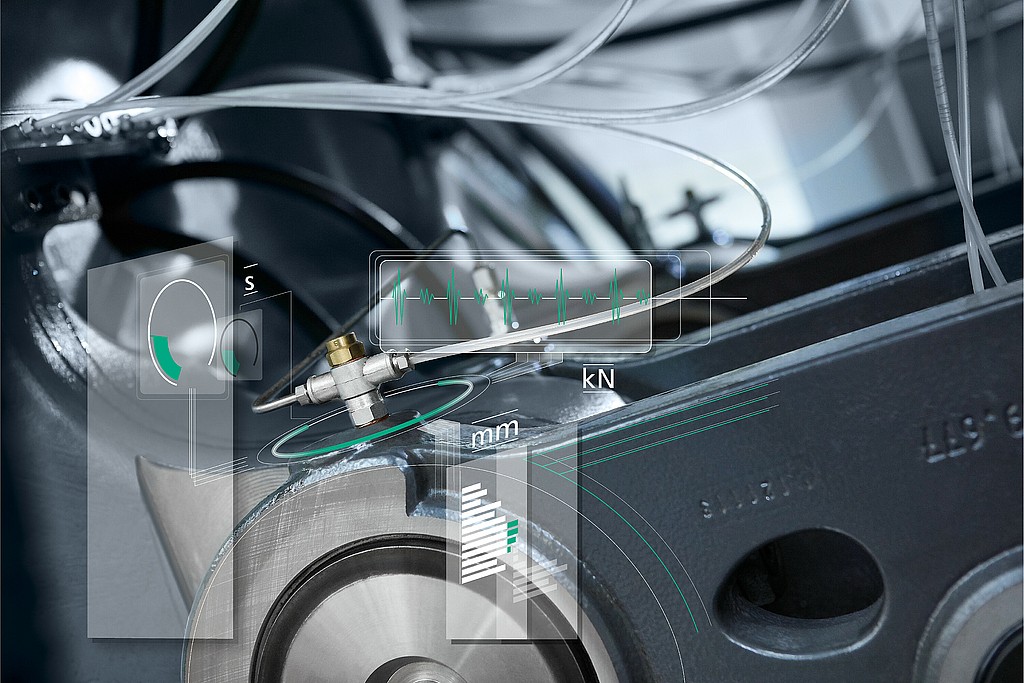

Reproducible injection with the “aXw Control ScrewPilot” | Higher injection speeds | Significantly higher injection speeds |

Servo hydraulics for simultaneous movement of a secondary axis and servo-electric main axes | GESTICA and servo-electric mould height adjustment system as standard | ULTIMATE+ alternative with injection speeds up to 400 mm/s |

COMFORT+ alternative with increased injection speeds | Extended equipment for special and multi-component processes | |

Part examples

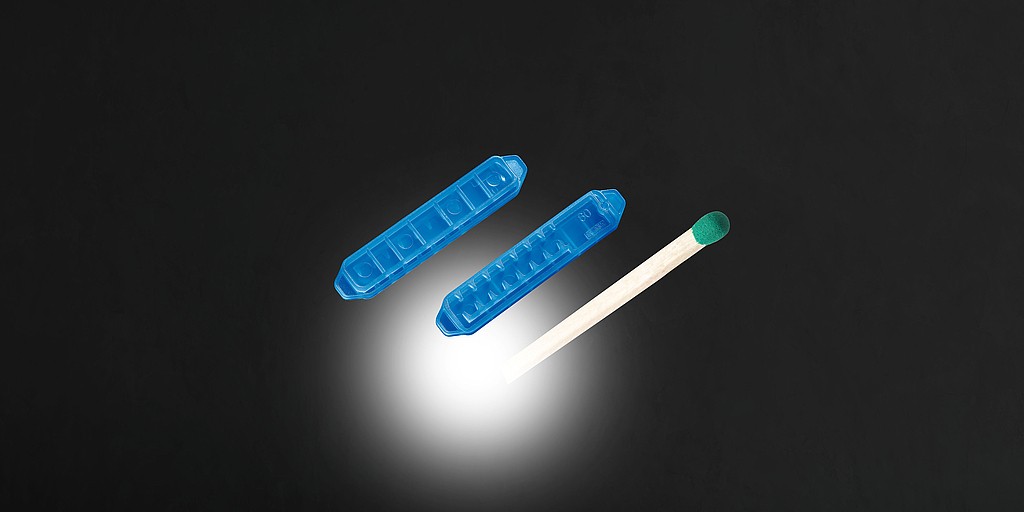

Micro cap

From the compact production cell: delicate LSR caps for microswitches are used, for example, in medical technology and mobility. Here parts of 0.008 g each, tested inline and packed in bags.

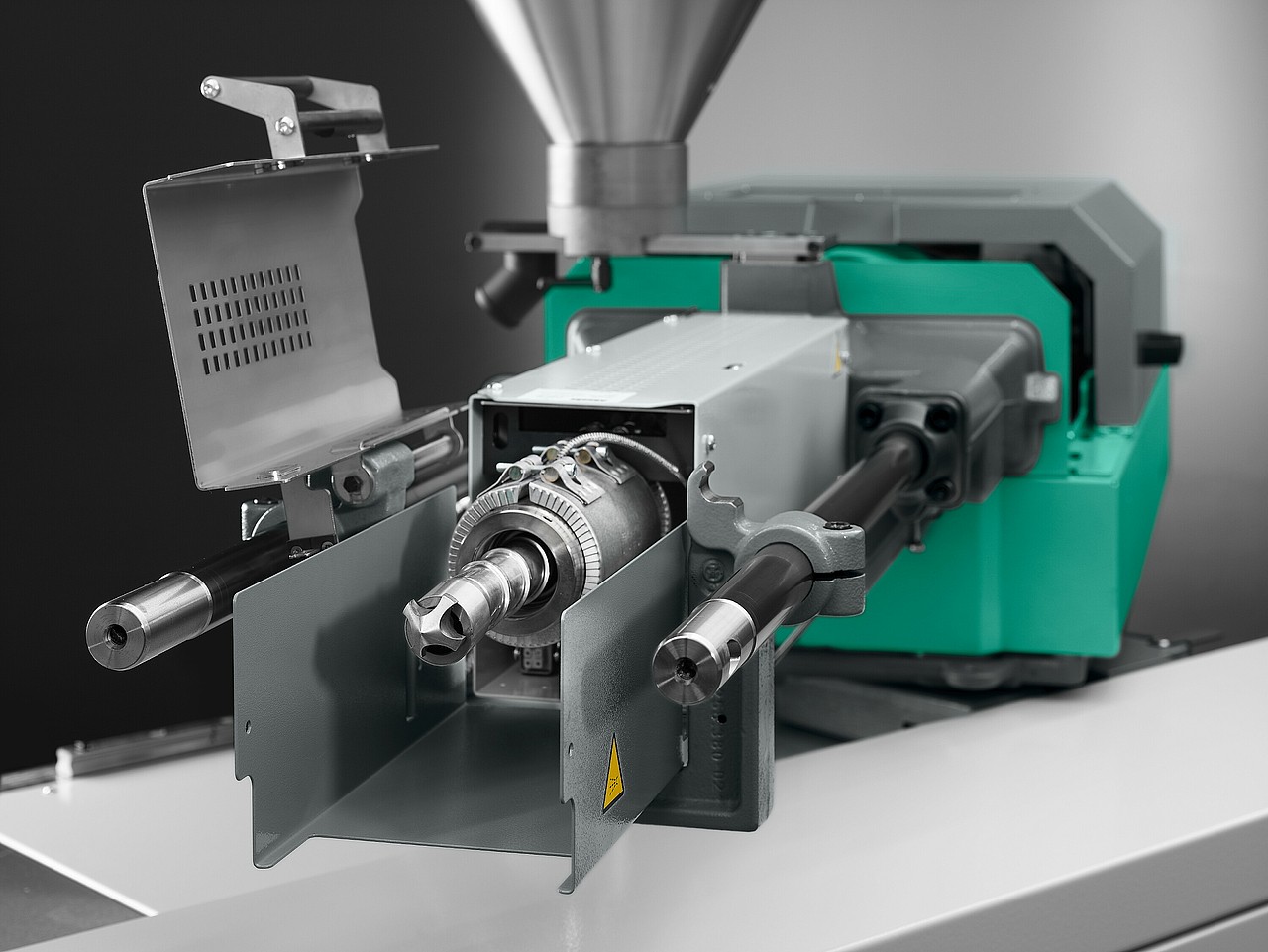

Flat dripper

Flat drippers for resource-saving irrigation are becoming necessary in more and more regions of the world. Challenge of delicate structures, produced on electric ALLROUNDERs.

Training Courses

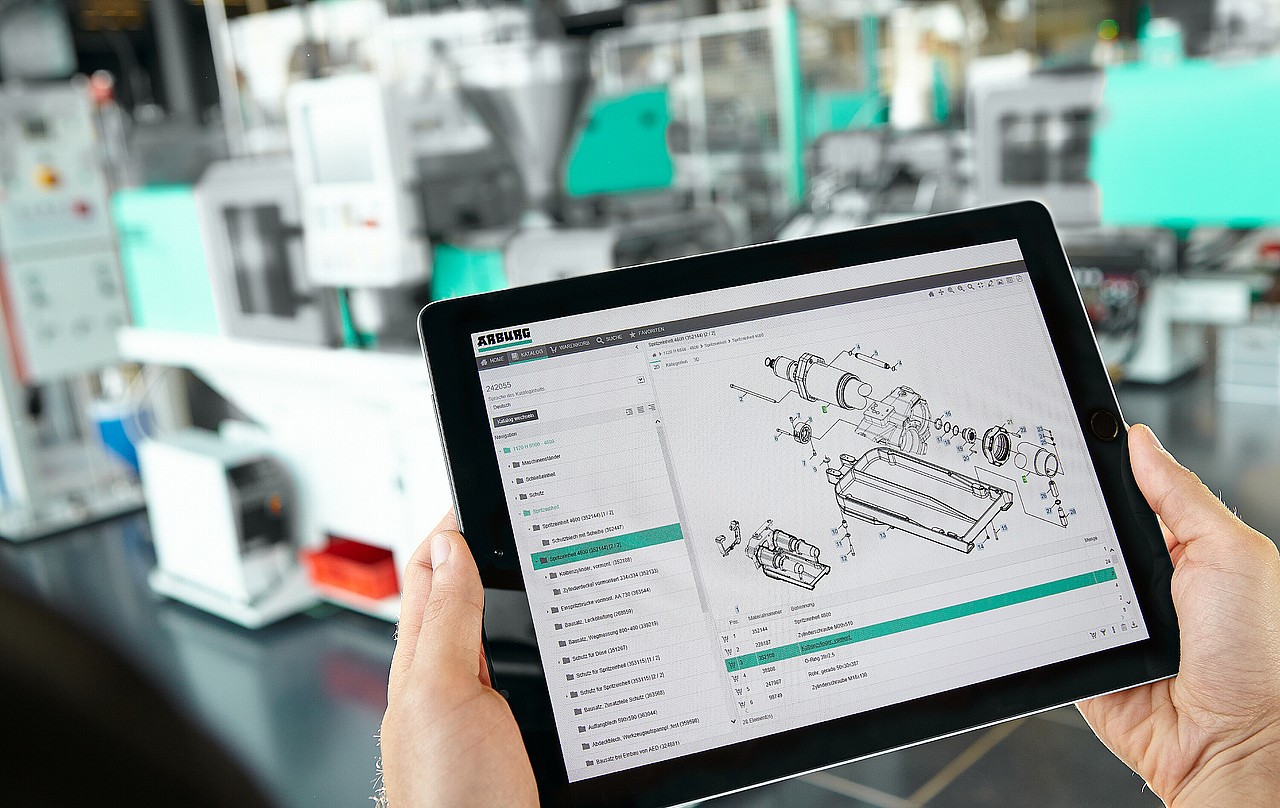

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also interest you

Electronics, medicine, mobility, packaging, complex components for a wide range of sectors and industries. This is where you excel. So do our machines and solutions.

If you expect top performance in thermoplastics processing, choose the hybrid ALLROUNDER injection moulding machines featuring a combination of hydraulic and electric axes.

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Allow yourself be inspired to new ideas by our component selection.