IML cups only 0.37 millimetres thick

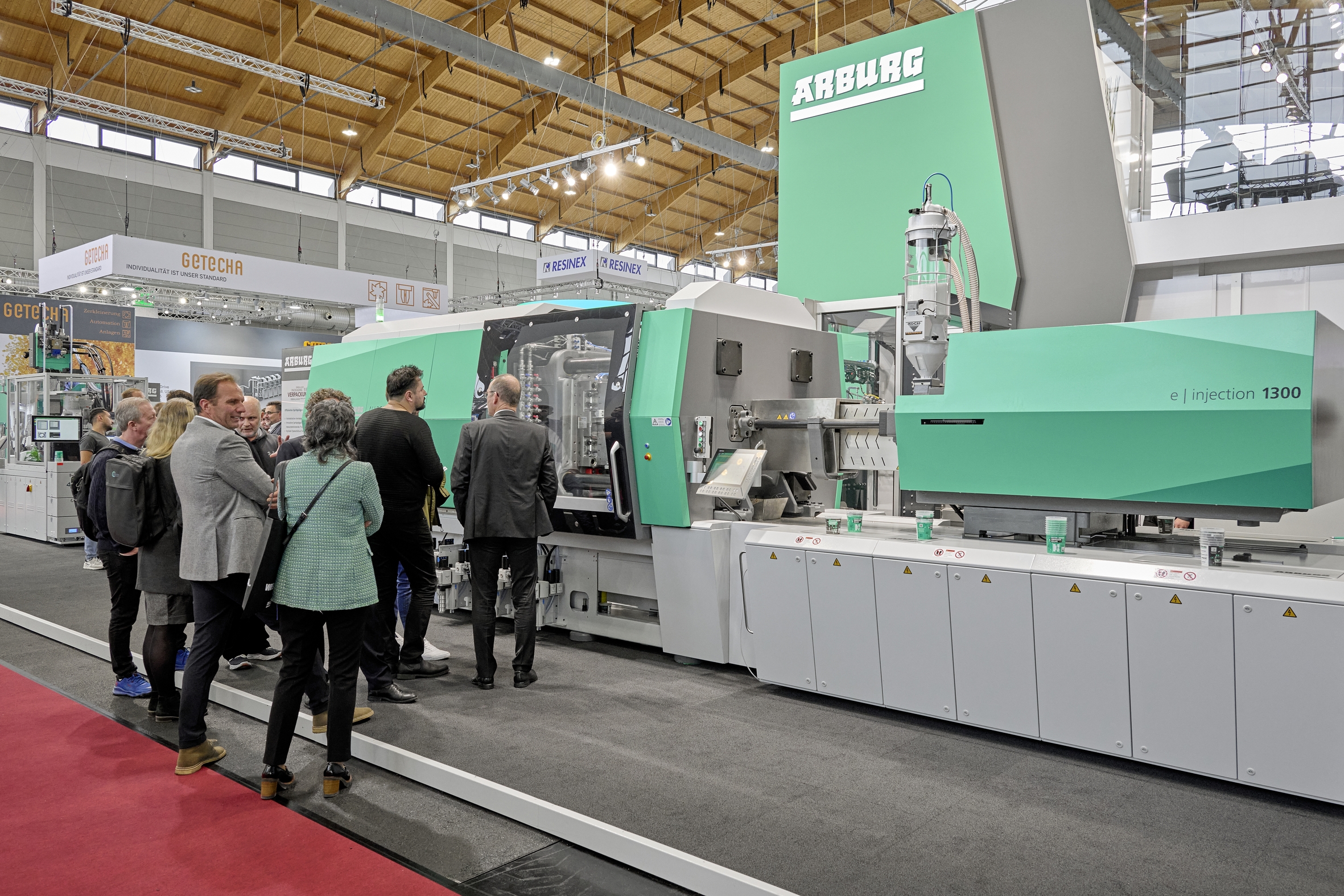

The exhibit uses a 4-cavity mould from Brink to produce thin-walled IML round cups from polypropylene (PP) using compression moulding at an injection pressure of just 23,000 psi (1,600 bar). For process monitoring, the mould is equipped with six high-resolution inductive position measuring and embossing sensors. Four moulded parts, each weighing 10.4 grams and with a wall thickness of only 0.37 millimetres, are produced in a cycle time of 3.95 seconds. The plastic has a biomass footprint and ISCC-certified. Also integrated into the production cell is a side-entry robot from Brink that inserts the labels, removes the finished cups and stacks them on a conveyor belt.