Advantages at a glance

Sector specific

Tailored exactly for your purposes - customer-specific, sector-specific: modularity and individual equipment. Ideal for the flexible overmolding of inserts.

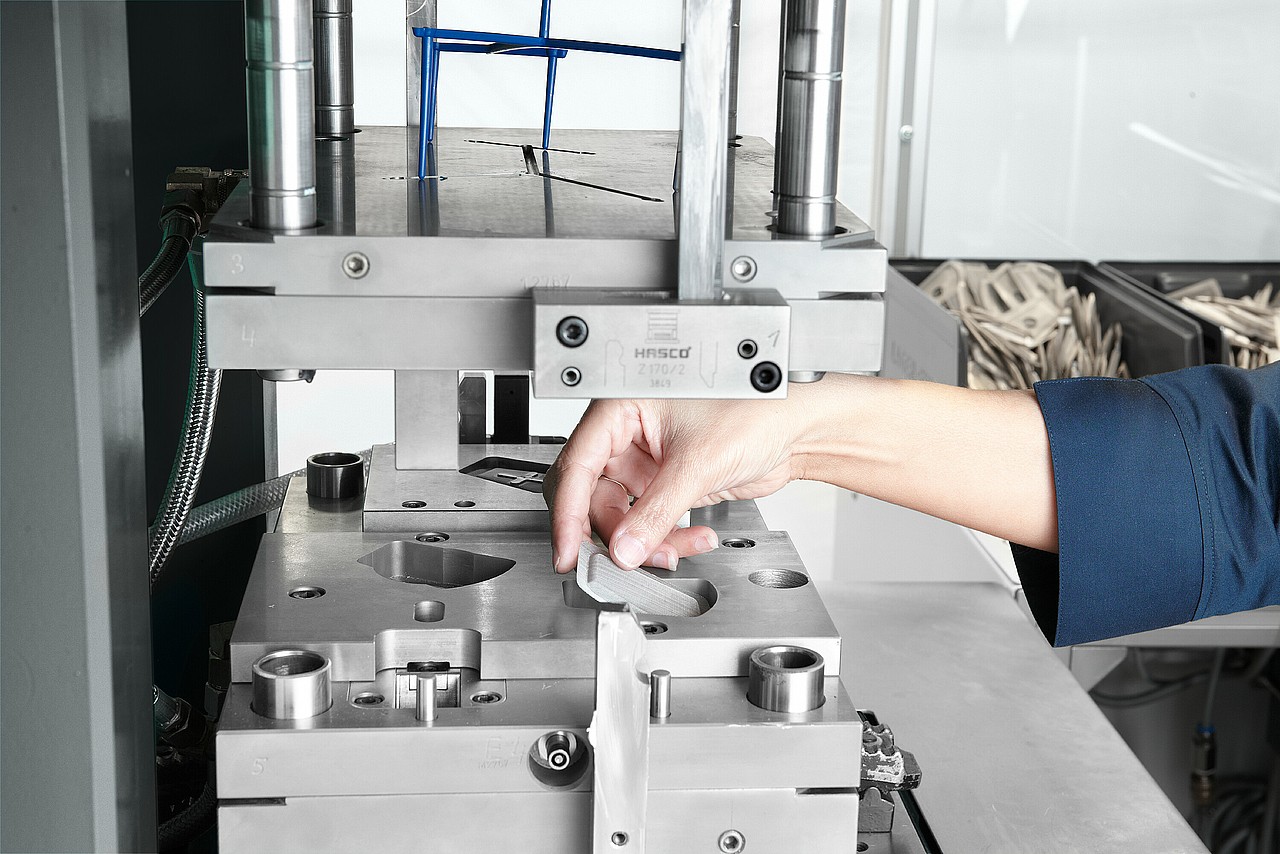

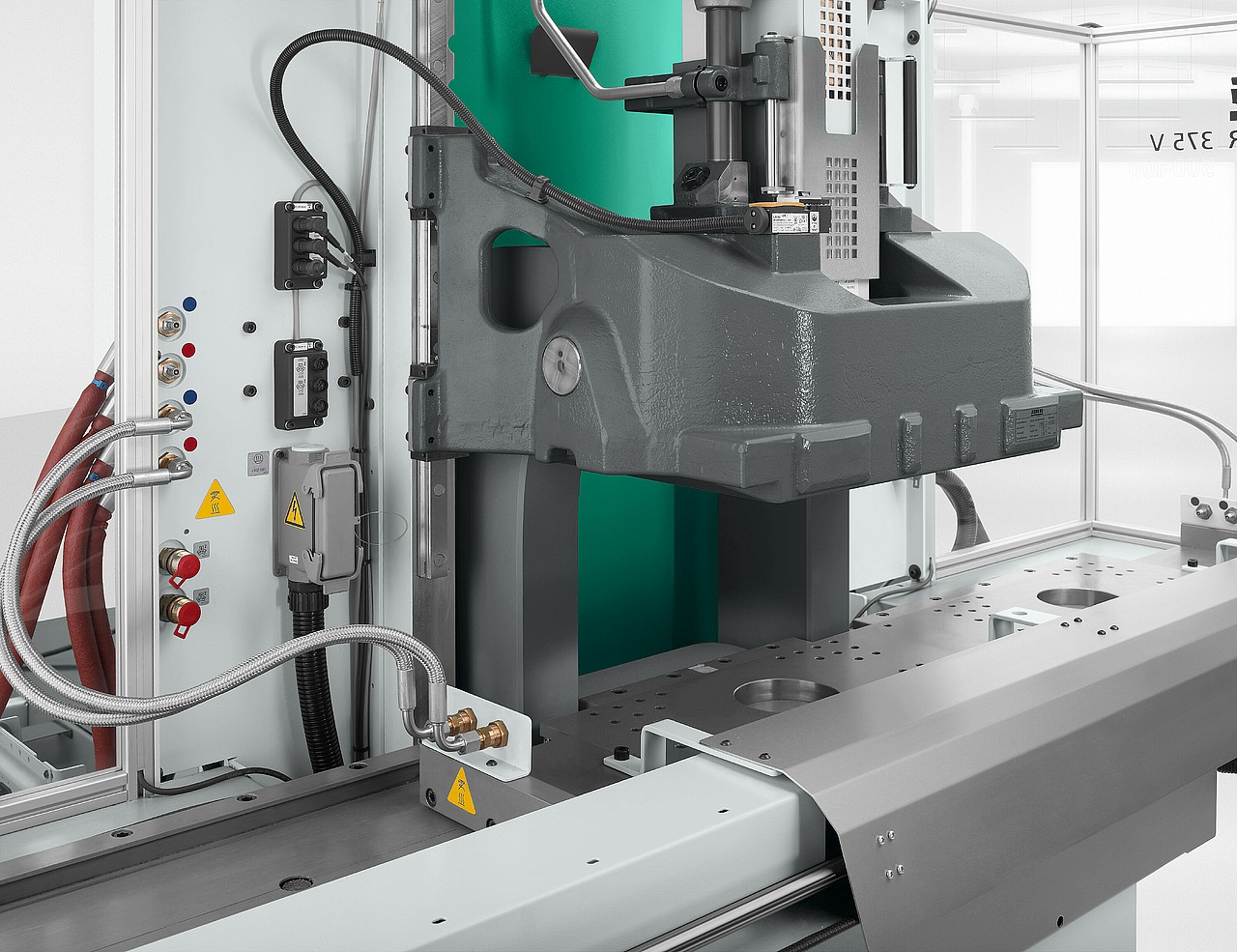

Free access

Thanks to the vertical free-space system, the mold is freely accessible from three sides and can be removed and inserted during the injection process. Manual or fully automated.

Ergonomic

For ergonomic and safe operations: low table heights and guards, plus numerous equipment and configuration options.

Easy on the mould

High rigidity, precision and parallelism of the vertical clamping units for minimum wear. Plus swivel-mounted C frame, optimum force transmission and mold protection.

Technical data

Component examples

icam connector

Digital cameras (icams) assist car drivers when parking. The secure connection between the camera and the electronics is ensured by eight-pin connectors with seals, manufactured on a two-component rotary table machine – two million units per year.

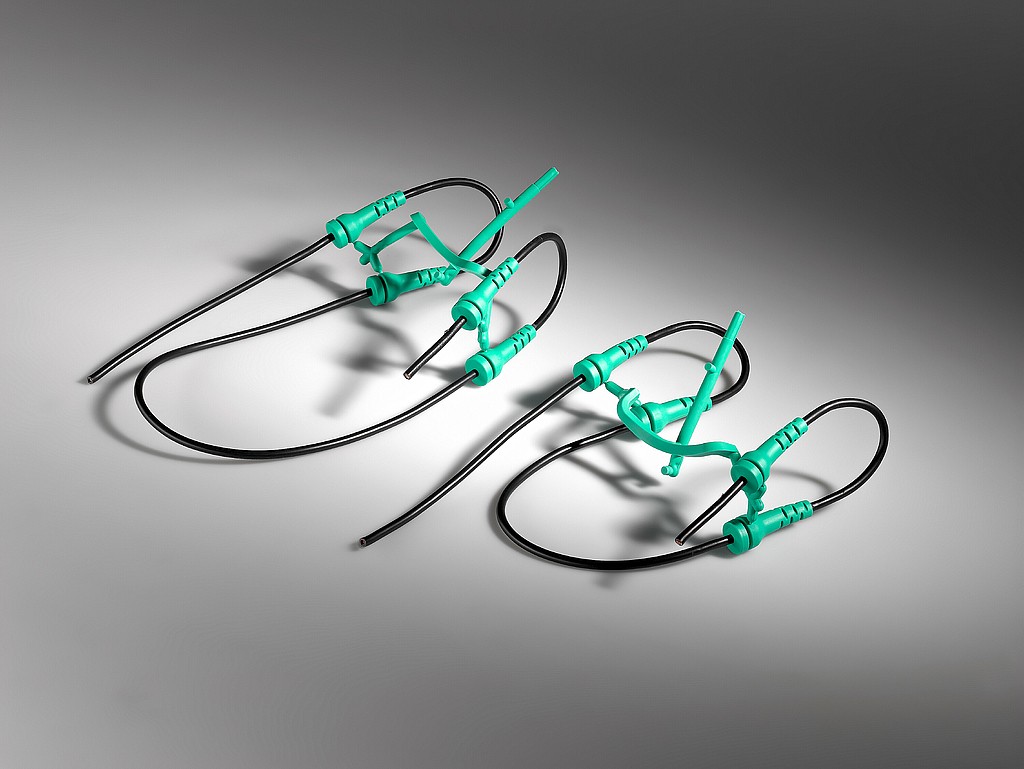

Cable grommet

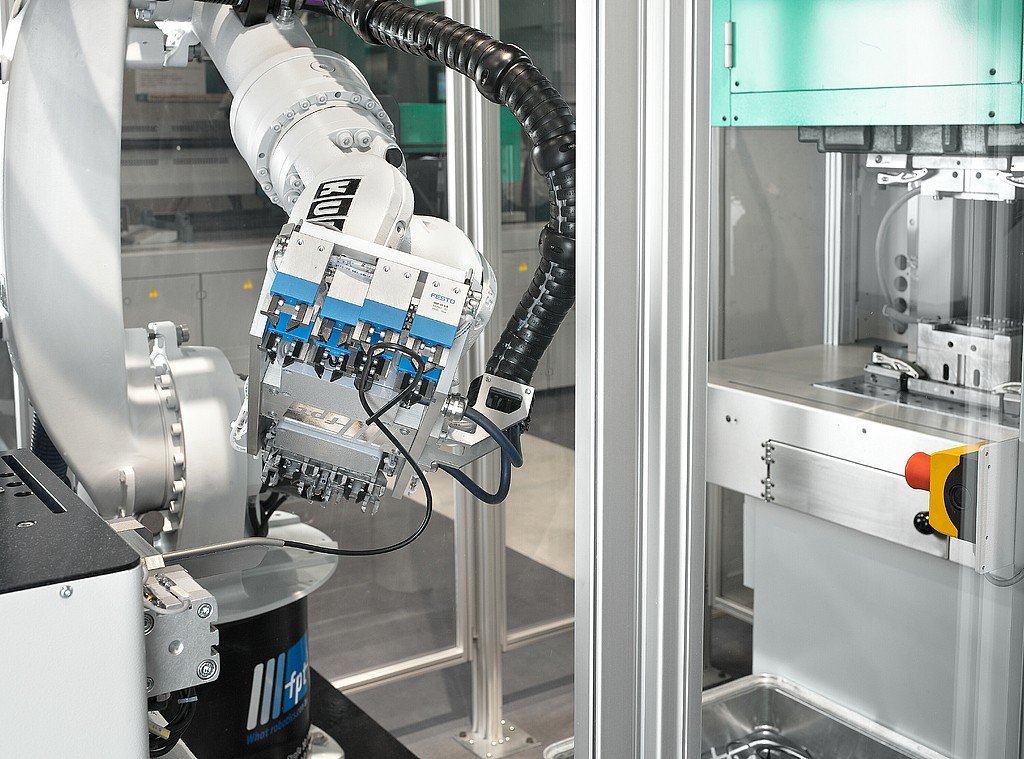

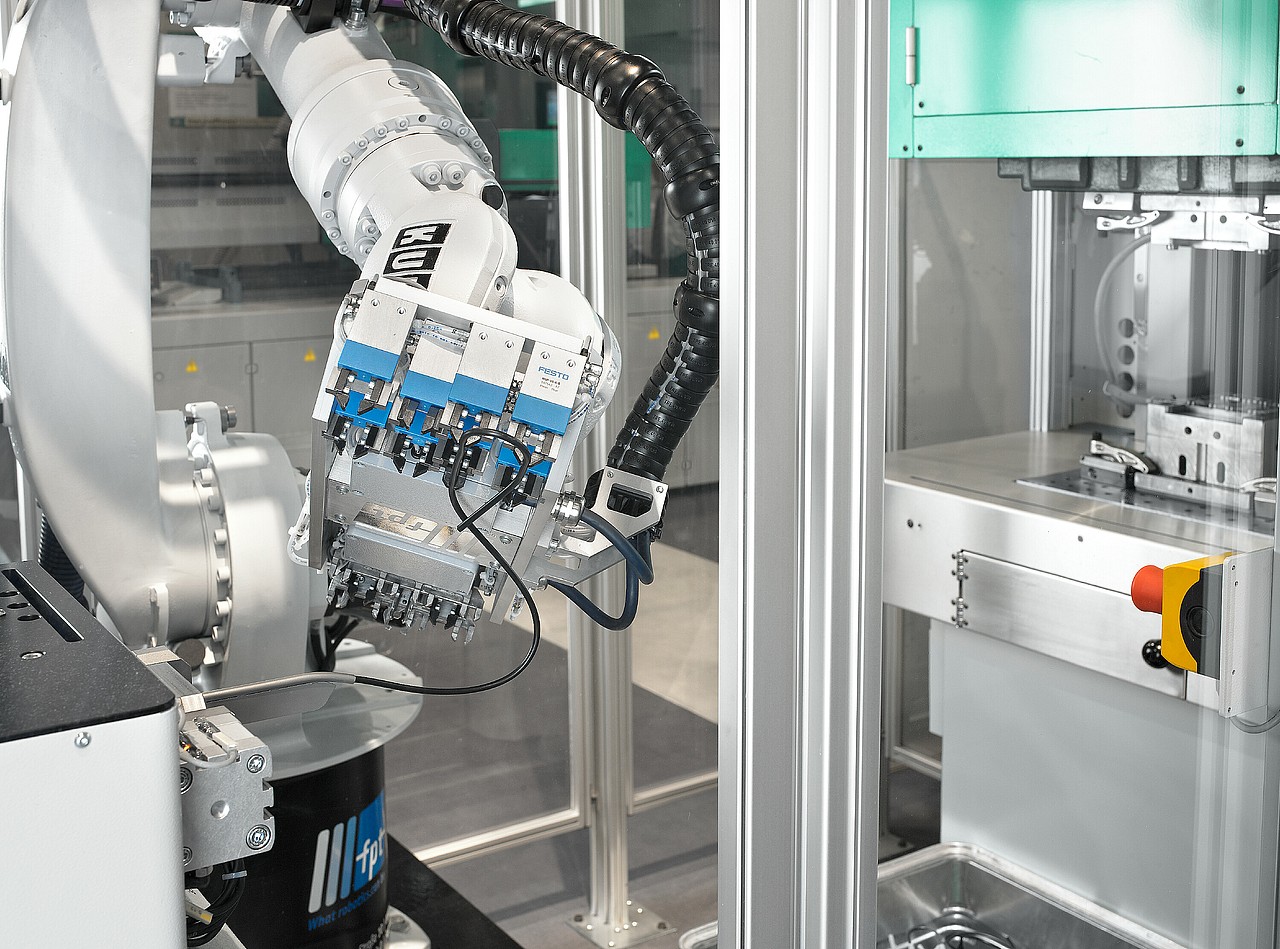

With the six-axis robots, you get flexible motion artists for complex tasks in your team. For example, you can individually prefabricate flexible parts and insert them into several cavities at different locations.

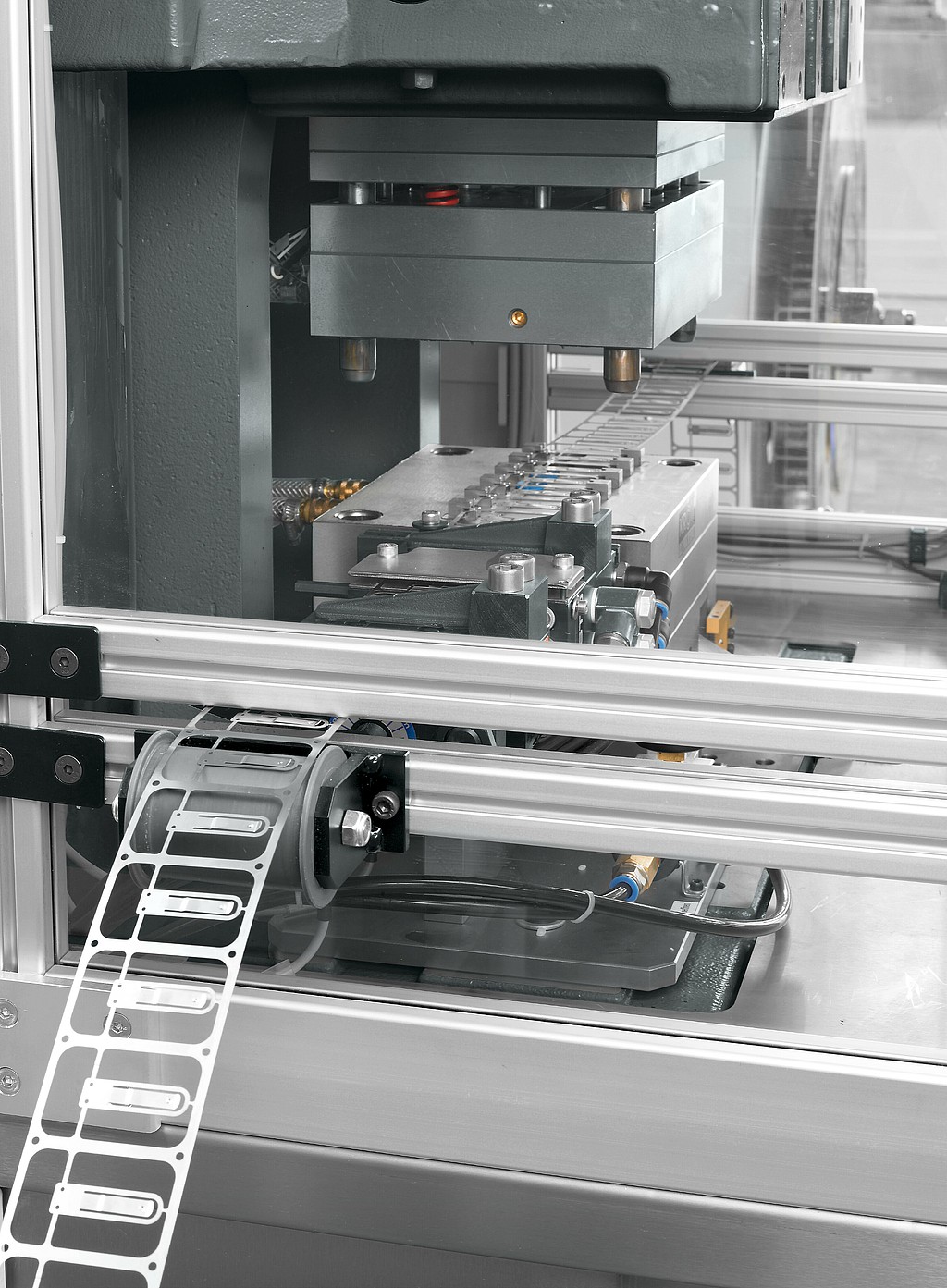

Plug insert

Pre-punched metal pins made of PA6 become plug inserts on a vertical ALLROUNDER V. These pre-molded parts are then overmolded again with an electric ALLROUNDER and assembled into hybrid connectors.

Training Courses

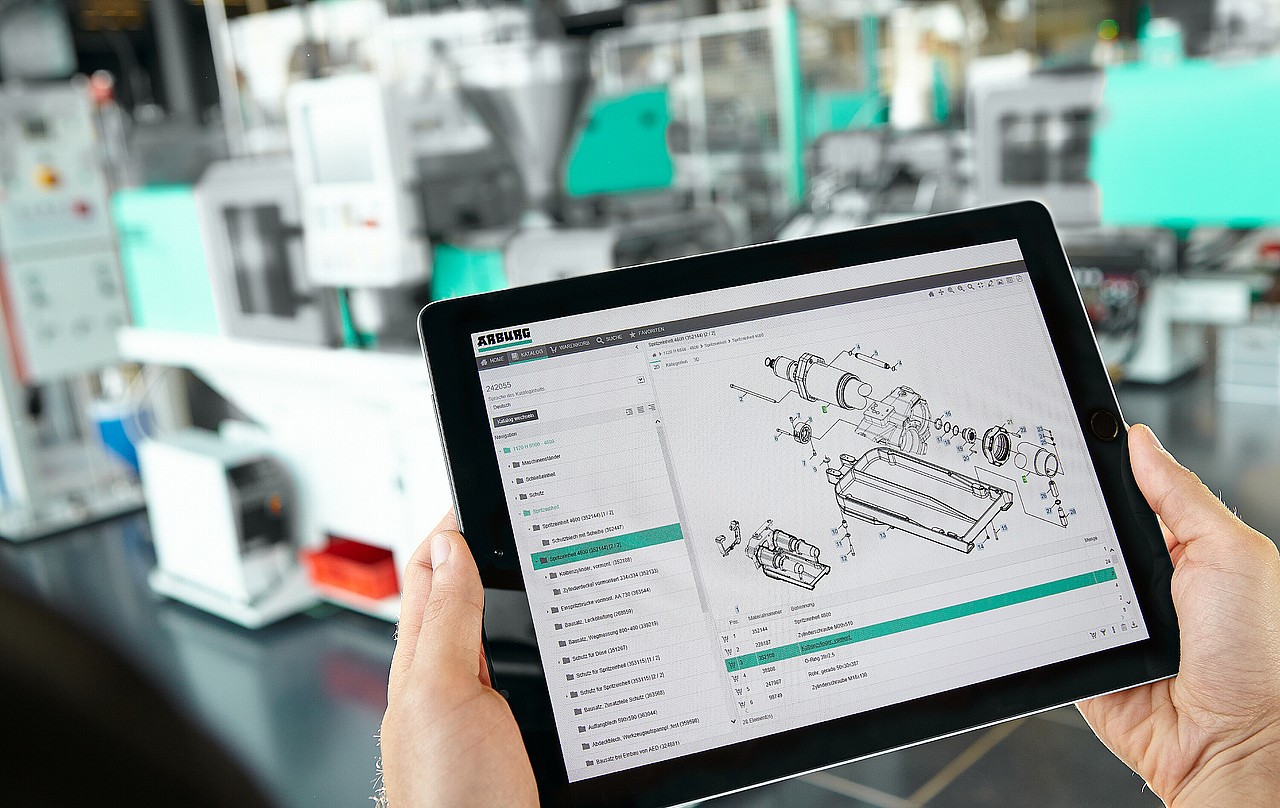

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then use our arburgXworld store for easy and interactive ordering.

This might also interest you

What do you need for your multi-component technology? Very flexible configurations. Our modular ALLROUNDERs offer this. With our technology and advice, we provide solutions tailored precisely to your production requirements.

Increase added value, optimize the injection molding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

We offer every freedom for your plastic product ideas. Or for hybrid components in combination with metal. The modular ALLROUNDER injection molding technology allows you to reliably overmold inserts with thermoplastic, thermoset or liquid silicone.