Benefits at a glance

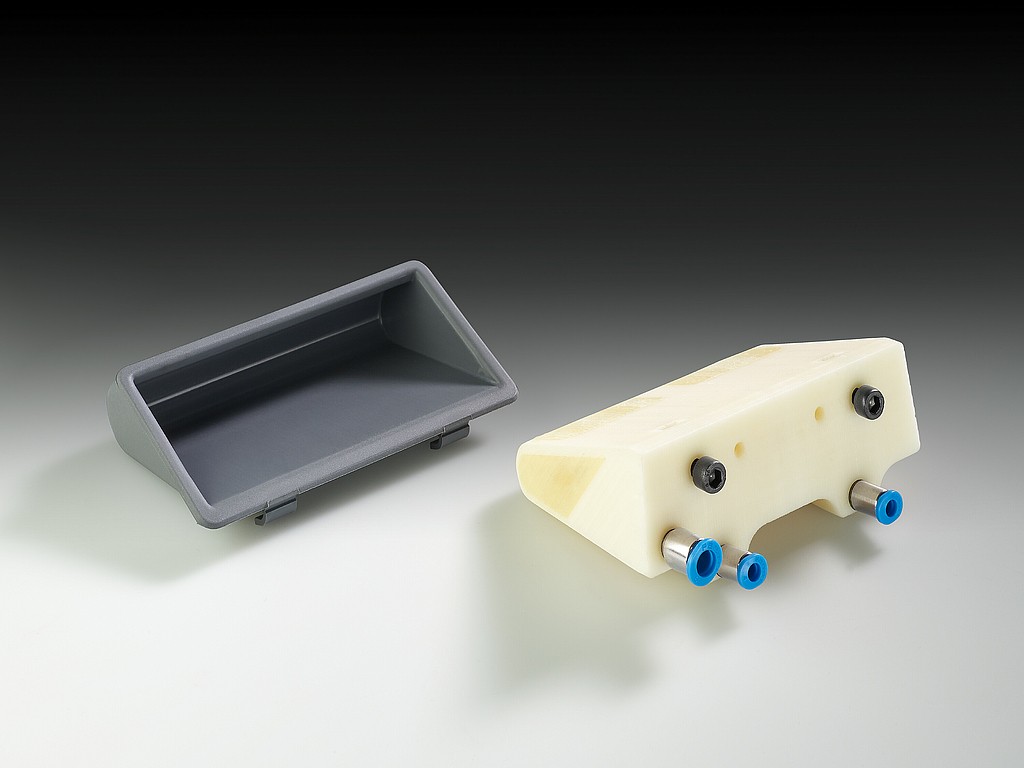

Limitless

The choice of materials is practically limitless: certified original materials, combinations of materials and colors, also in resilient hard/soft combinations, soluble support materials – everything is possible!

Open

The open ARBURG Plastic Freeforming (APF) system offers you maximum freedom in the additive processing of qualified standard granules. By varying the process parameters, the component properties can be specifically influenced.

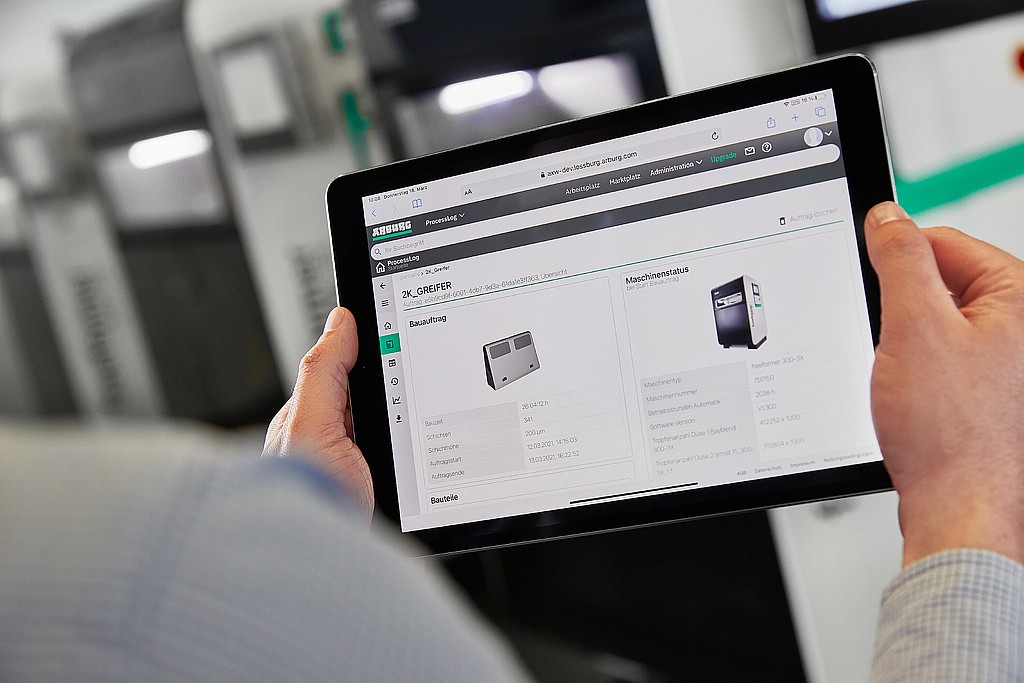

Traceable

The freeformer works reliably and reproducibly. Data can be seamlessly traced and documented via the ProcessLog customer portal app. For example, for medical technology or aerospace applications.

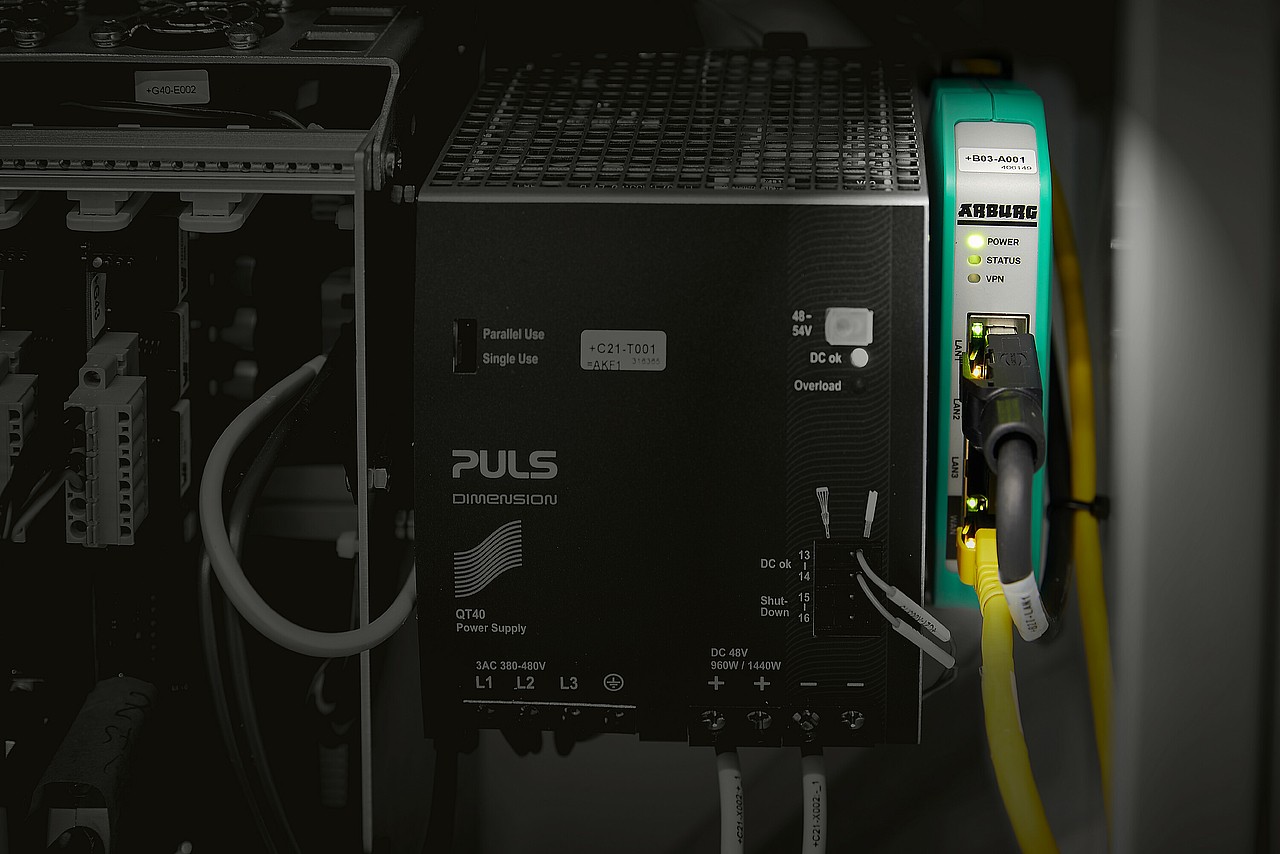

High-quality

Our high-end freeformer control system is designed for industrial use. With a clear multi-touch screen and easy-to-understand, intuitive user interface. Plus automated 3D slicing software for data preparation.

Technical data

Component examples

Implants

Resomer LR 706, for example, is used to make resorbable implants that can be inserted directly into the body after bone fractures.

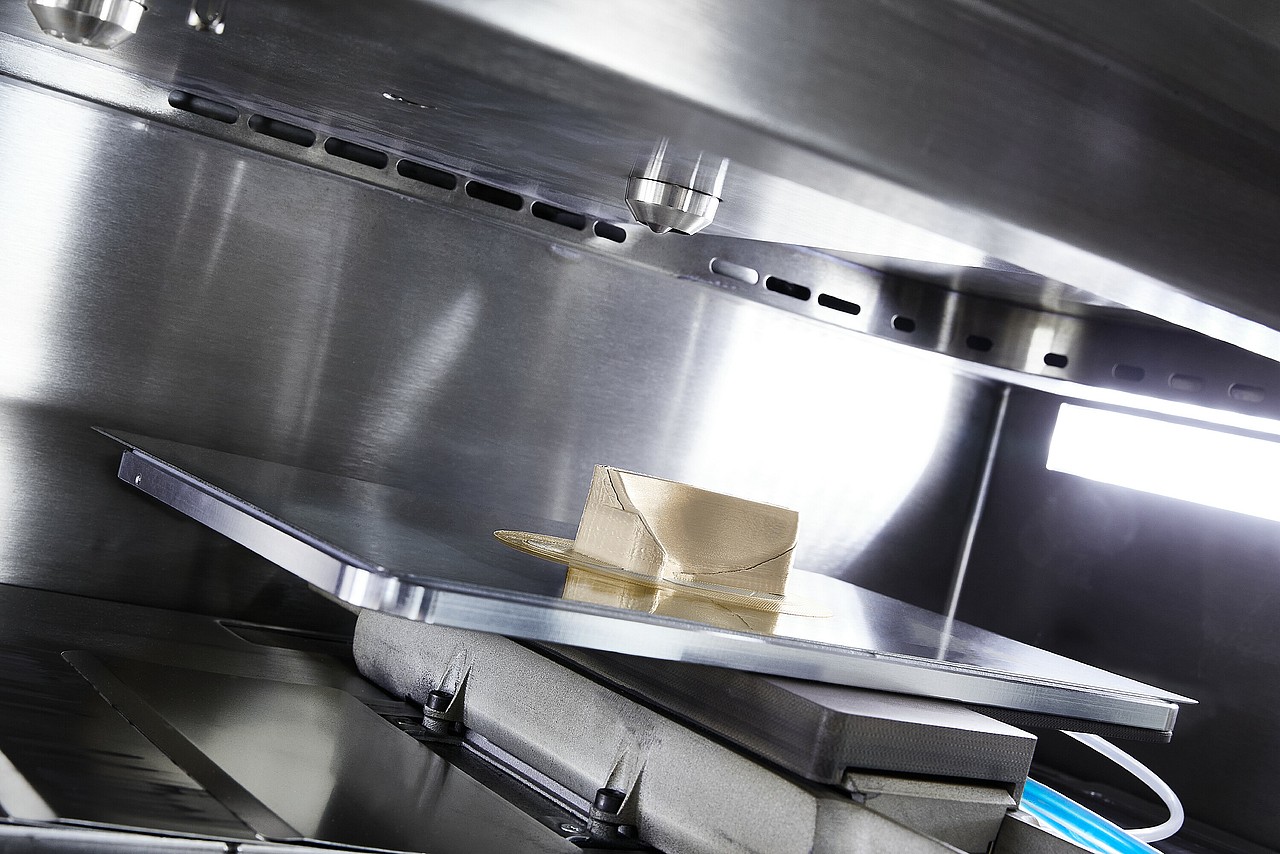

Honeycomb structure

The freeformer is ideal for soft materials such as TPE and TPU. The component density can be selectively influenced in order to produce flexible honeycomb structures, for example.

Film hinges

3D printing of original PP for prototyping film hinges. The freeformer produces flip-top closures that can be opened hundreds of times.

S-pipe

Thick-walled S-pipes can be additively manufactured without distortion. With the aid of support materials, cleverly inserted and later dissolved in a water bath with no finishing work.

Pressure-sensitive adhesive

freeformers can even process pressure-sensitive adhesive granules, as tesa has shown. This has great potential for applications such as the waste-free bonding of smartphone components.

Newsletter registration

Want to stay up to date on all things APF and freeformer? Then simply subscribe to our freeformer newsletter. Available in German or English.

This might also be of interest

Benefit from our first-class service at the ARBURG Prototyping Centers (APC) in Lossburg (Germany), Rocky Hill (U.S.) and Shanghai (China).

Want to meet us in person and experience our machines and applications live? Then you have the opportunity to do so at numerous trade shows and events.

Electronics, medicine, mobility, packaging, complex components for a wide range of areas. This is where you excel. So do our machines and solutions.