Construction and equipment engineering

Phoenix Contact relies on an ARBURG turnkey solution that combines efficient automation with high article variance.

Phoenix Contact relies on an ARBURG turnkey solution that combines efficient automation with high article variance.

Production concept with ARBURG turnkey system combines high article variance with automation.

Cycle times reduced by a third and mould and gripper set-up time halved.

After quality control and with no finishing work, only flawless parts leave the system.

The decision was made to use a turnkey solution based around an electric ALLROUNDER 470 A. A Kuka Agilus articulated arm robot picks up the individually conveyed bushings and places them at predefined positions on a moving mould platen for transfer. The moving mould platen and gripper each fit a mould cassette with one, two or four cavities. The mould platens that are not currently in use are stored on two gripper trolleys that can be moved to the system for an easier changeover.

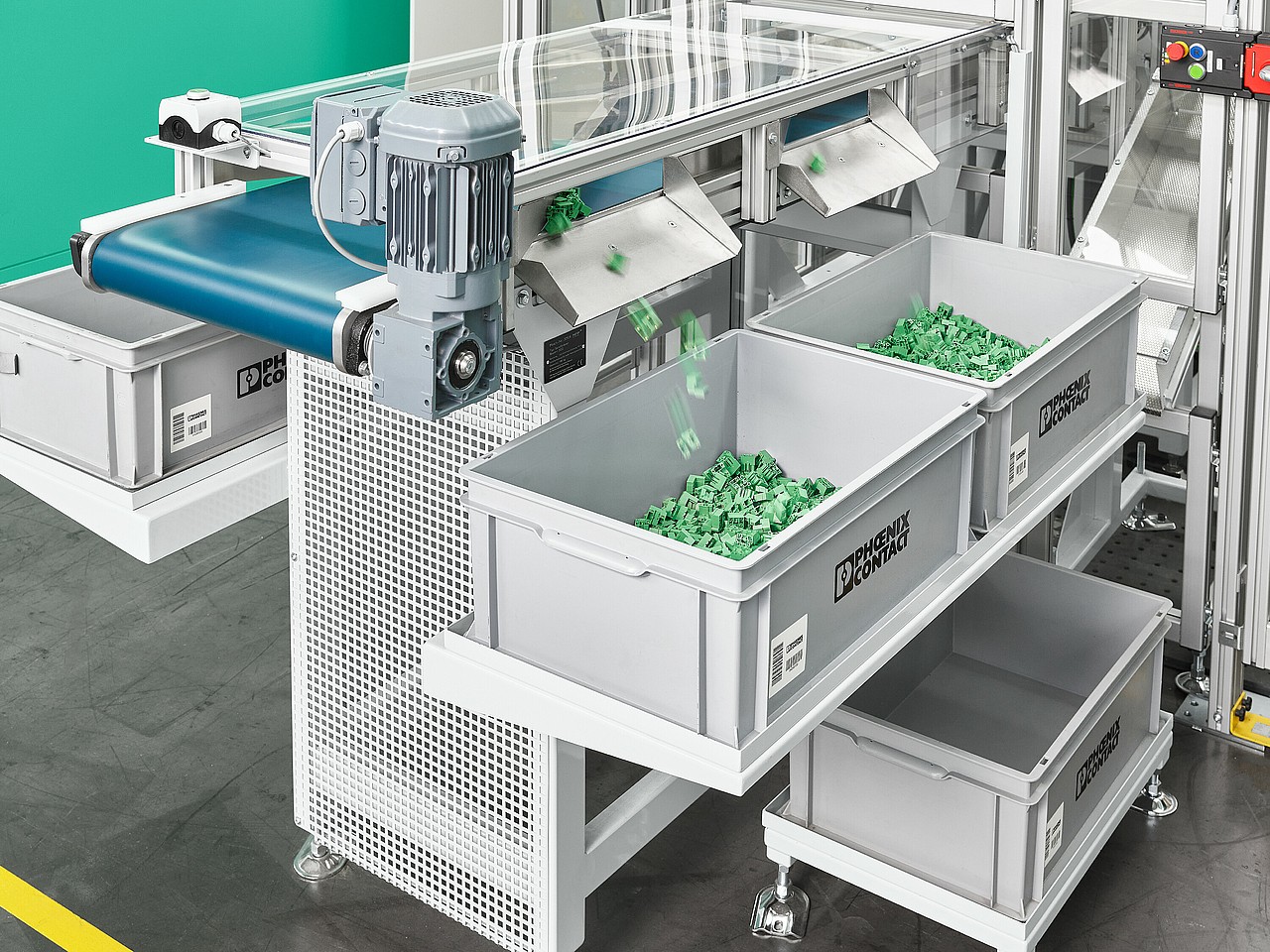

A MULTILIFT V linear robotic system picks up the bushings, inserts them into the mould and simultaneously removes the sprue and moulded parts. The sprue is discharged into a sprue grinder, where it is regranulated and returned to the process. The bushings are inductively tested, subjected to a quality check and then thrown into transport containers separated by cavity.

Thanks to the new machine mould concept, the high requirements for short cycle times have not only been met, but far exceeded. In future, this will enable series production and product diversity with just one system.

“We are combining article variance with automation – and we're doing so with high product quality and low cycle and set-up times.”

Bernd Laumann, Team Manager Injection Moulding Projects PCC for Device Connectors