Benefits at a glance

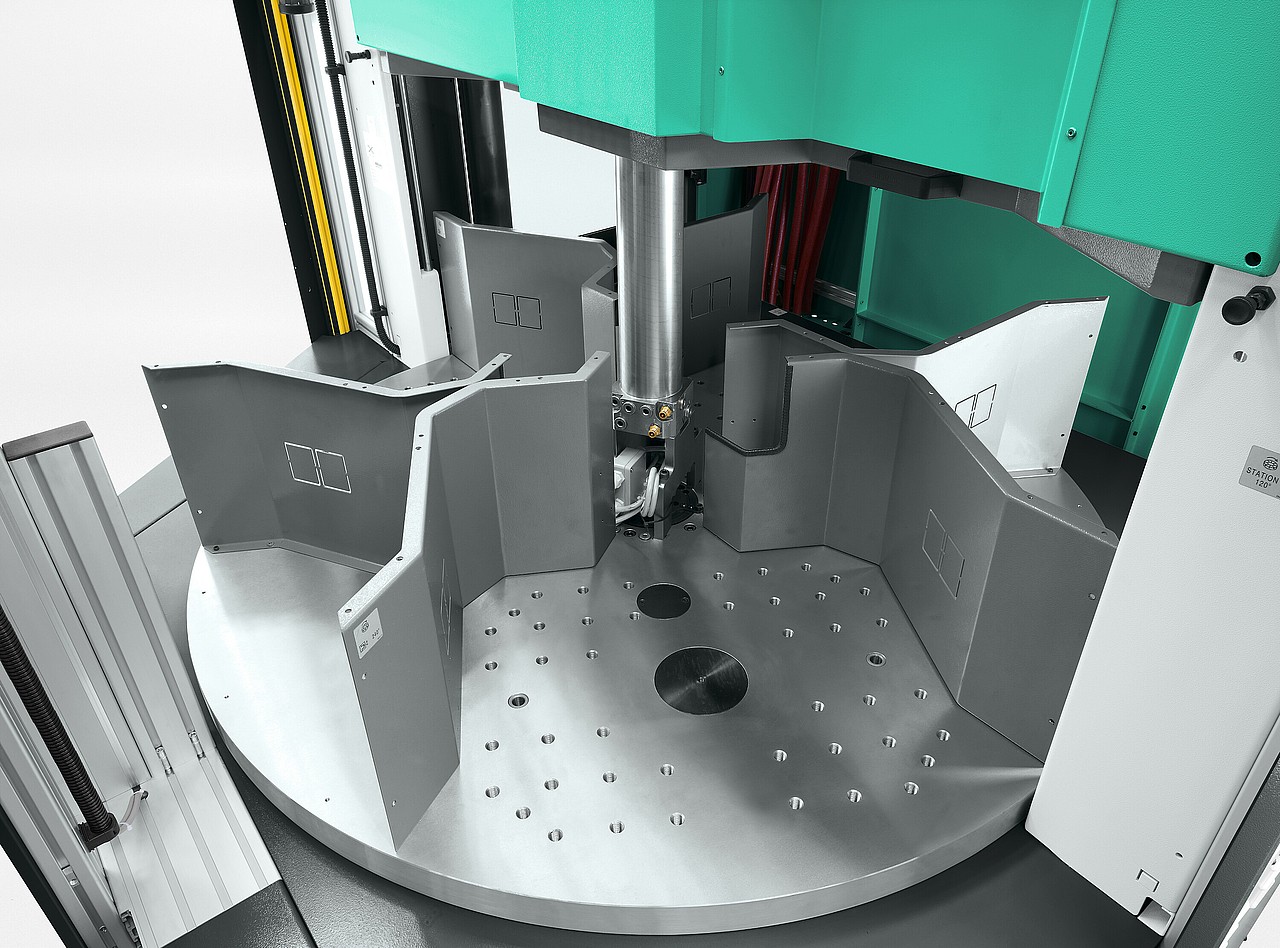

Graduated

There is a choice of machines with finely graduated sizes and different injection units. The rotary tables are generally servo-electrically driven.

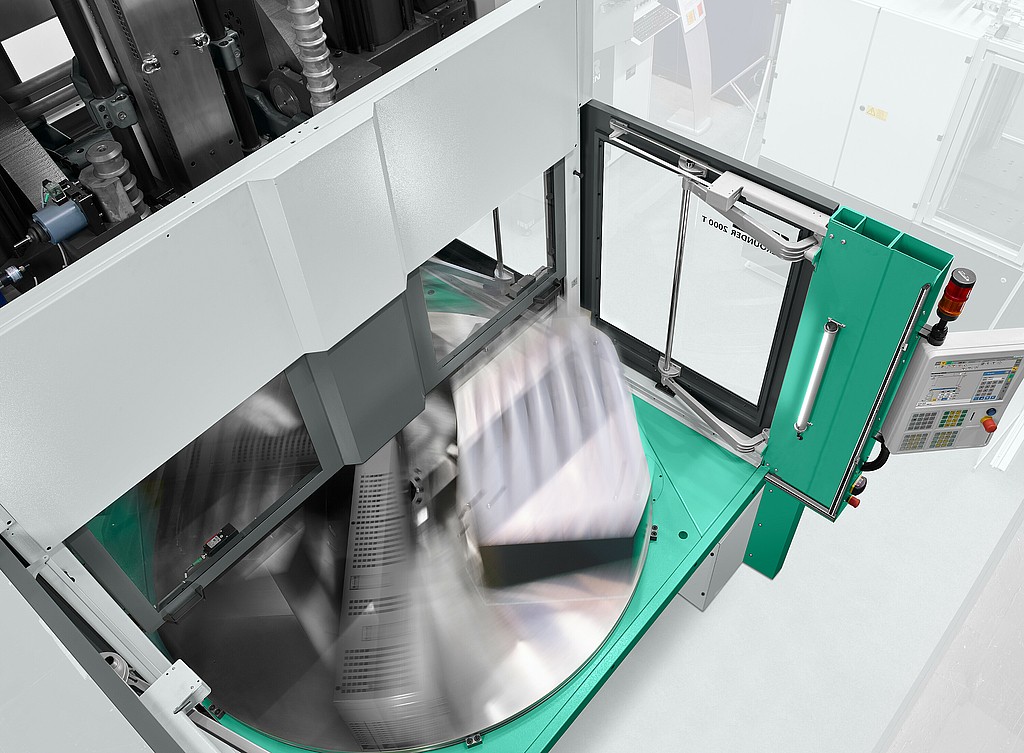

Simultaneously

Allowing you to work simultaneously with the moulding process: take advantage of the versions with rotary and shuttle tables. Because the vertical free-space system is the ideal solution.

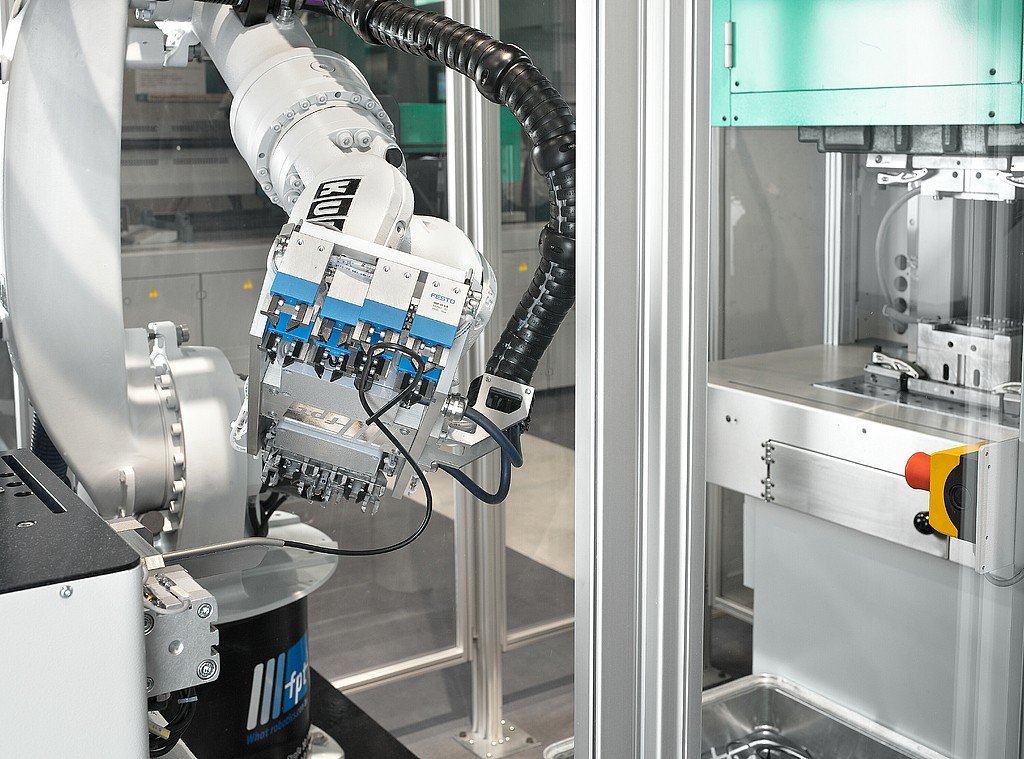

Automatable

Vertical ALLROUNDER T machines can be easily integrated into automated production lines. As a primary contractor, we also offer turnkey systems from a single source.

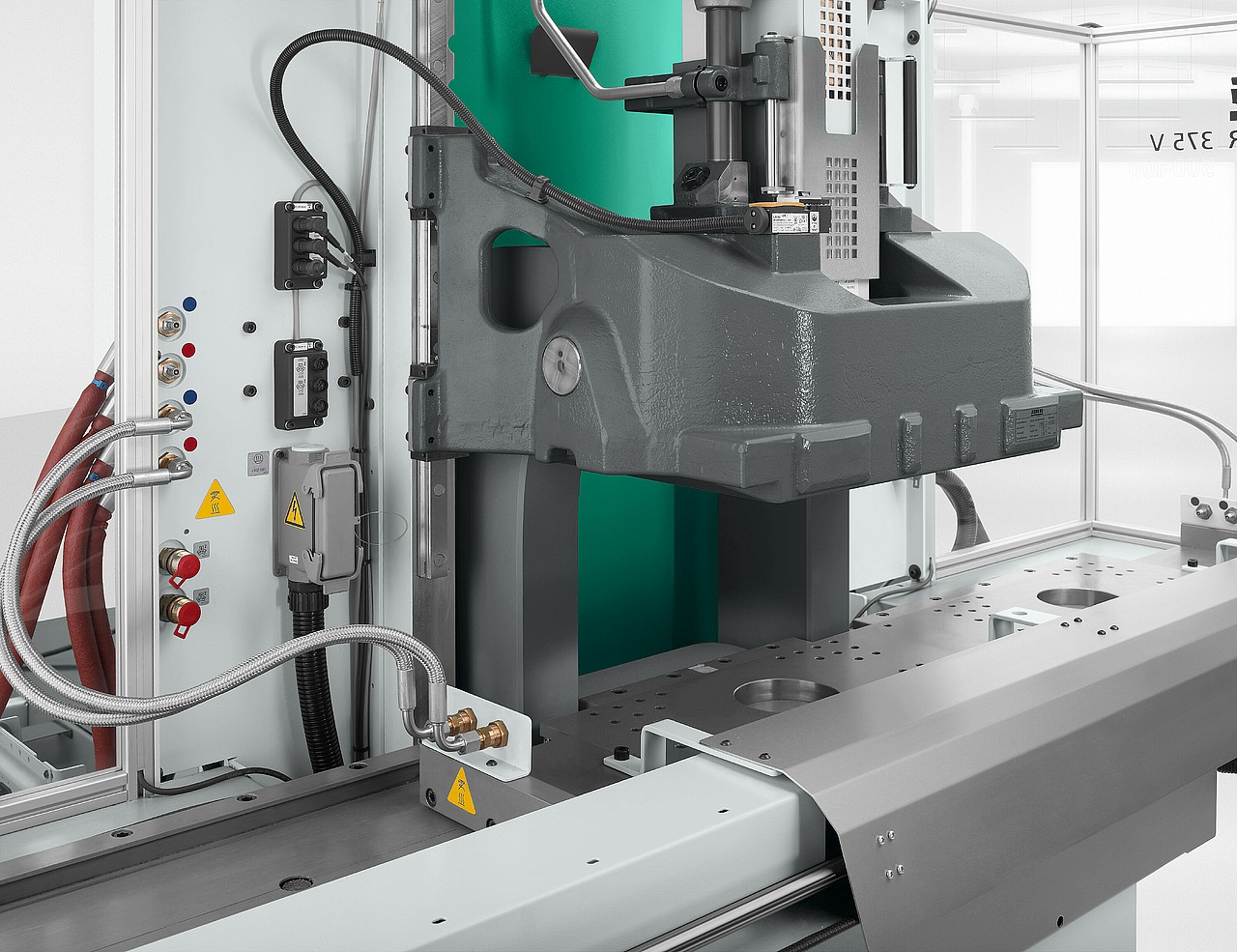

Hair-trigger precision

The ALLROUNDER T delivers precise results, particularly in demanding areas such as medicine or mobility – thanks to pressure accumulator and "smart" control features.

Technical data

Part examples

icam connector

Digital cameras (icams) assist car drivers when parking. The secure connection between the camera and the electronics is ensured by eight-pin connectors with seals, manufactured on a two-component rotary table machine – two million units per year.

Laptop cover

Lightweight construction in multi-material design and a combination of high-gloss and textured surfaces (Class A) is the way to a high-quality laptop cover.

Training Courses

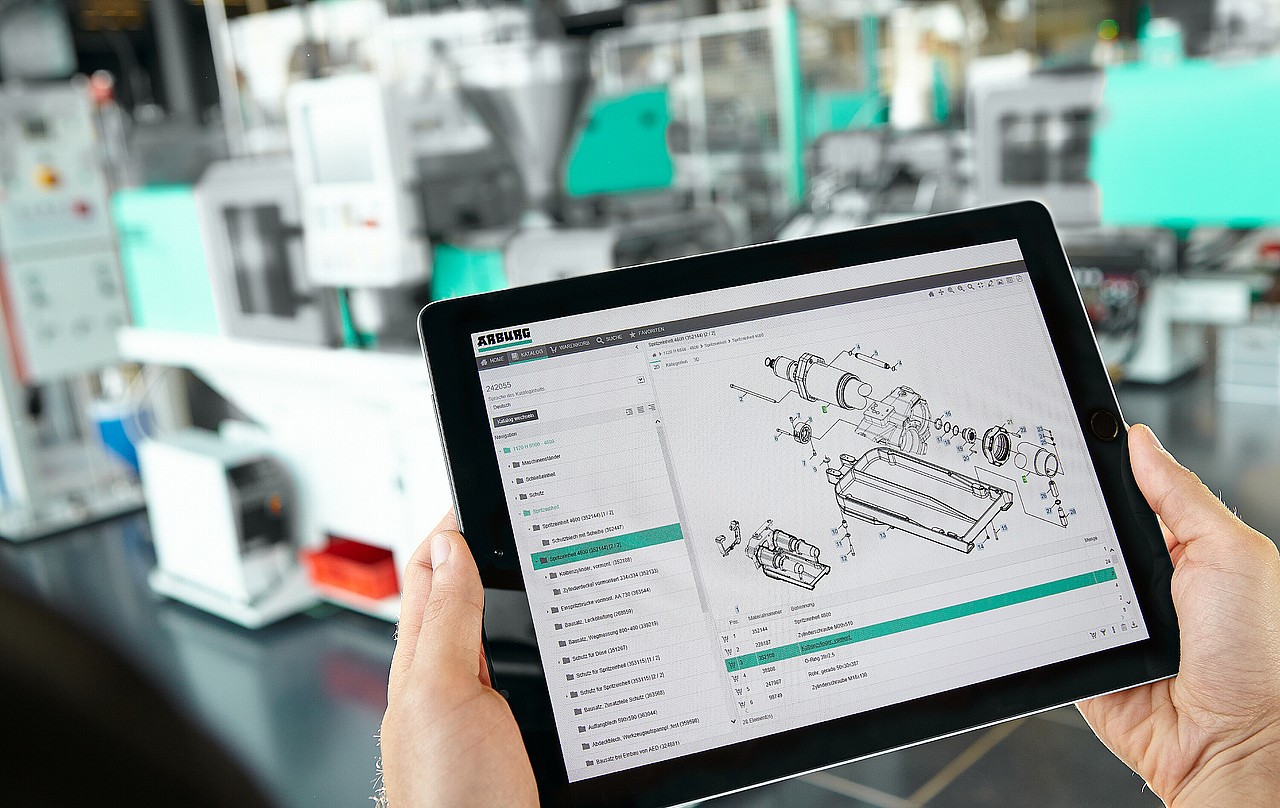

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also interest you

We know your industry. We know your materials. We have the accessories. And we can think ahead together when you are pursuing new possibilities in injection moulding.

Increase added value, optimise the injection moulding process, automate further, integrate innovatively? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

We offer every freedom for your plastic product ideas. Or for hybrid components in combination with metal. The modular ALLROUNDER injection moulding technology allows you to reliably overmould inserts with thermoplastic, thermoset or liquid silicone.