Benefits at a glance

Material-specific

For high-quality thermoset moulded parts you need suitable temperatures, special plasticising screws and venting, plus real expertise. And we have just that.

Tough

Looking for materials for tough cases? With granulated thermosets and moist polyester (BMC), you can achieve a high degree of mechanical strength and rigidity.

Resilient

Abrasion resistant, heat resistant, electrically insulating, resistant to chemicals? Then thermoset injection moulding is the answer. And ARBURG's expertise will be of interest to you.

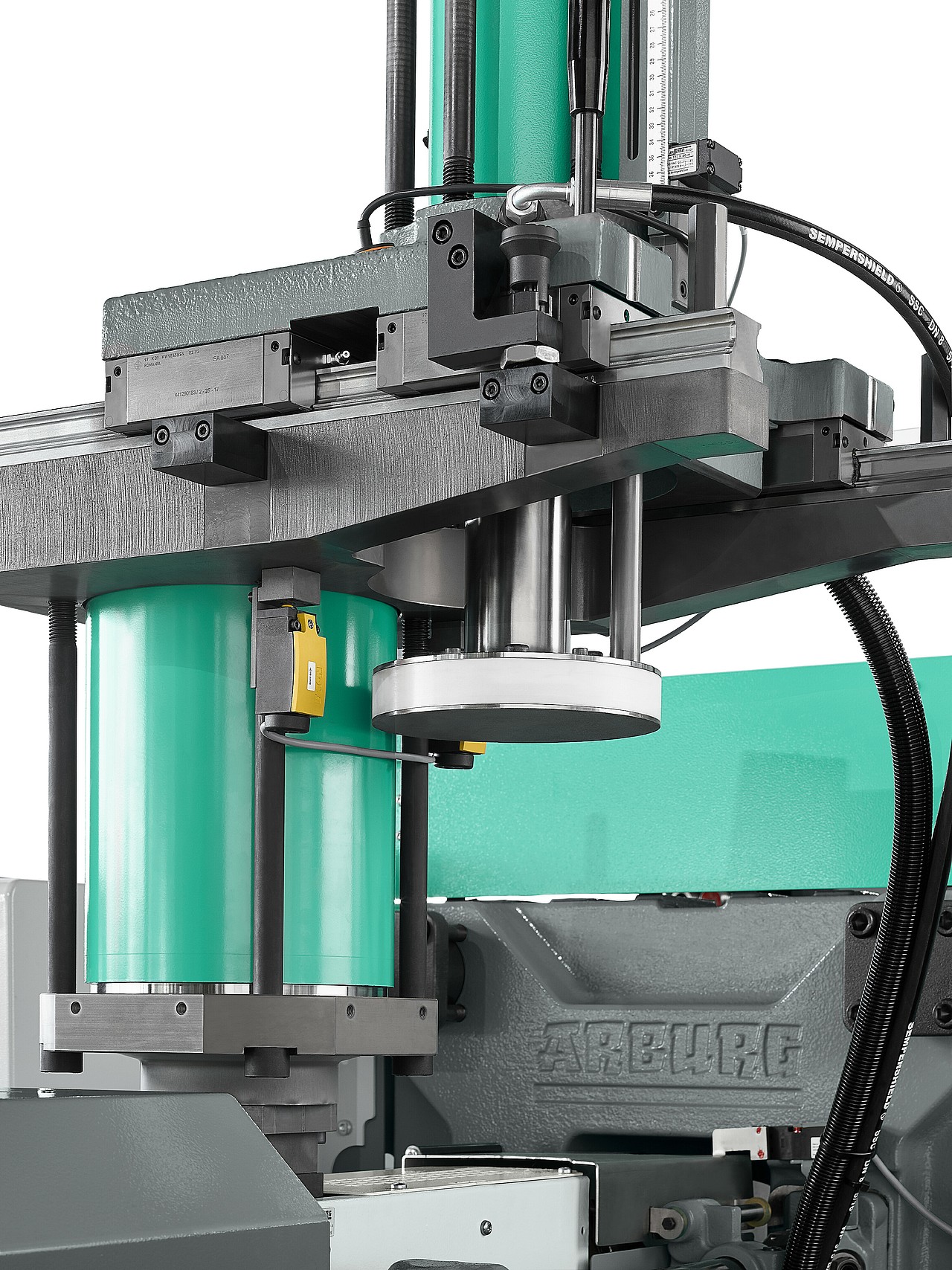

Combined

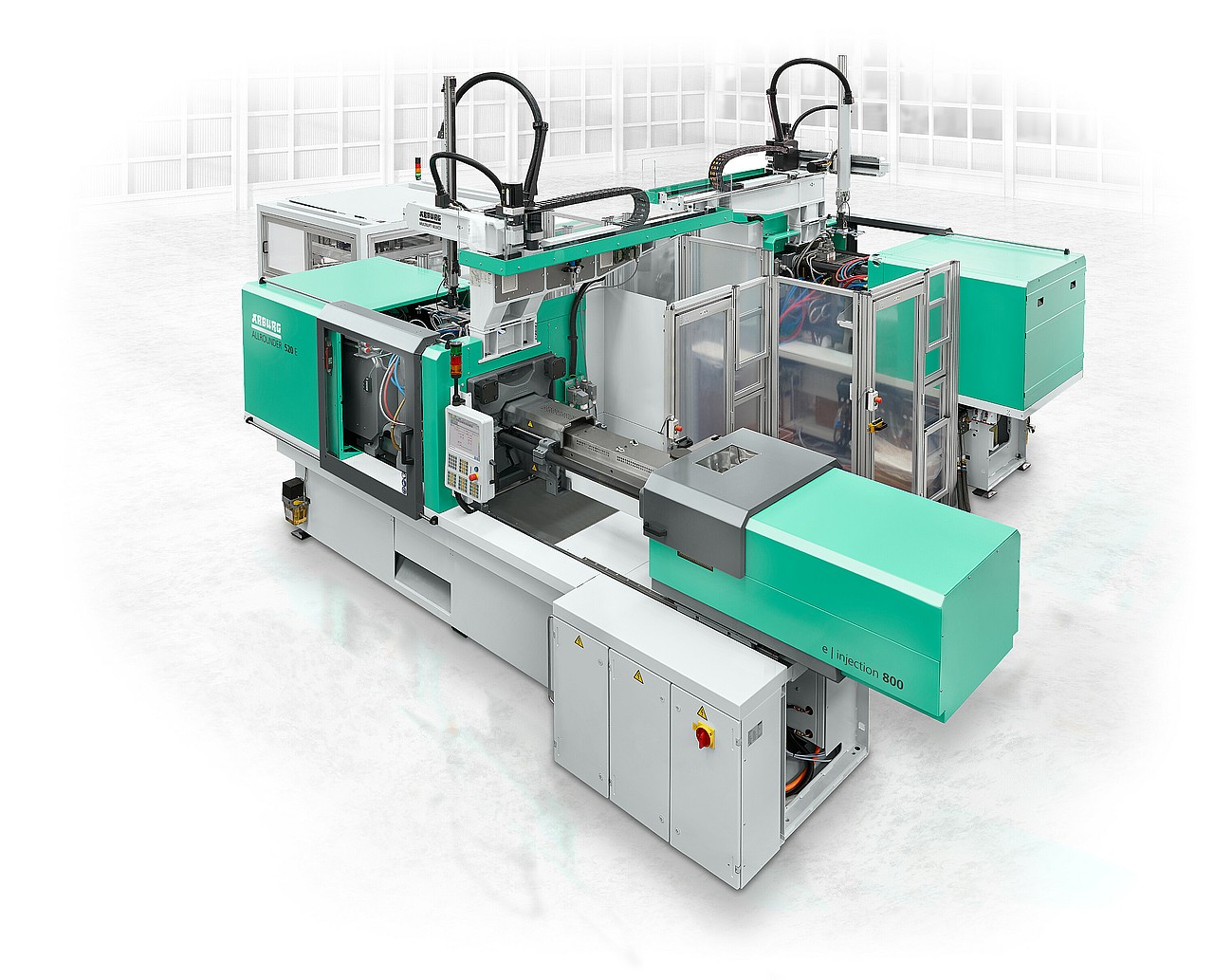

Reliable hydraulic or vertical ALLROUNDERs and a practice-oriented thermoset package: with this system solution, you can immediately start high-quality series production.

Benefits of thermoset injection moulding

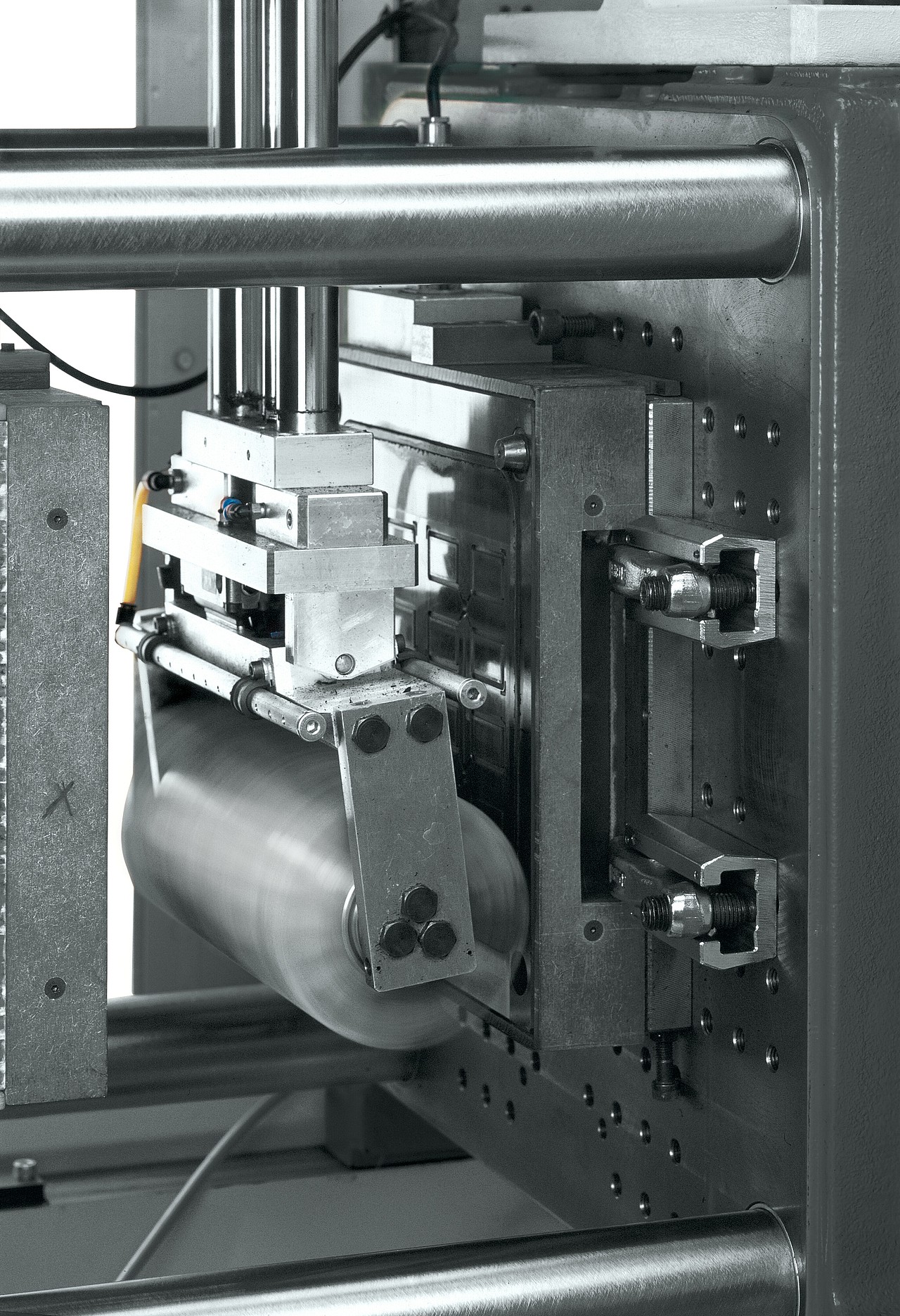

Short sprues

Short sprues

With temperature-controlled cold runner extended nozzles with an immersion depth of up to 100 mm for material-efficient work.

Reliable venting

Reliable venting

Reliable machine controller, air and cross-linking gases escape easily, parts with no shrink holes – also for repeated venting during the holding pressure phase.

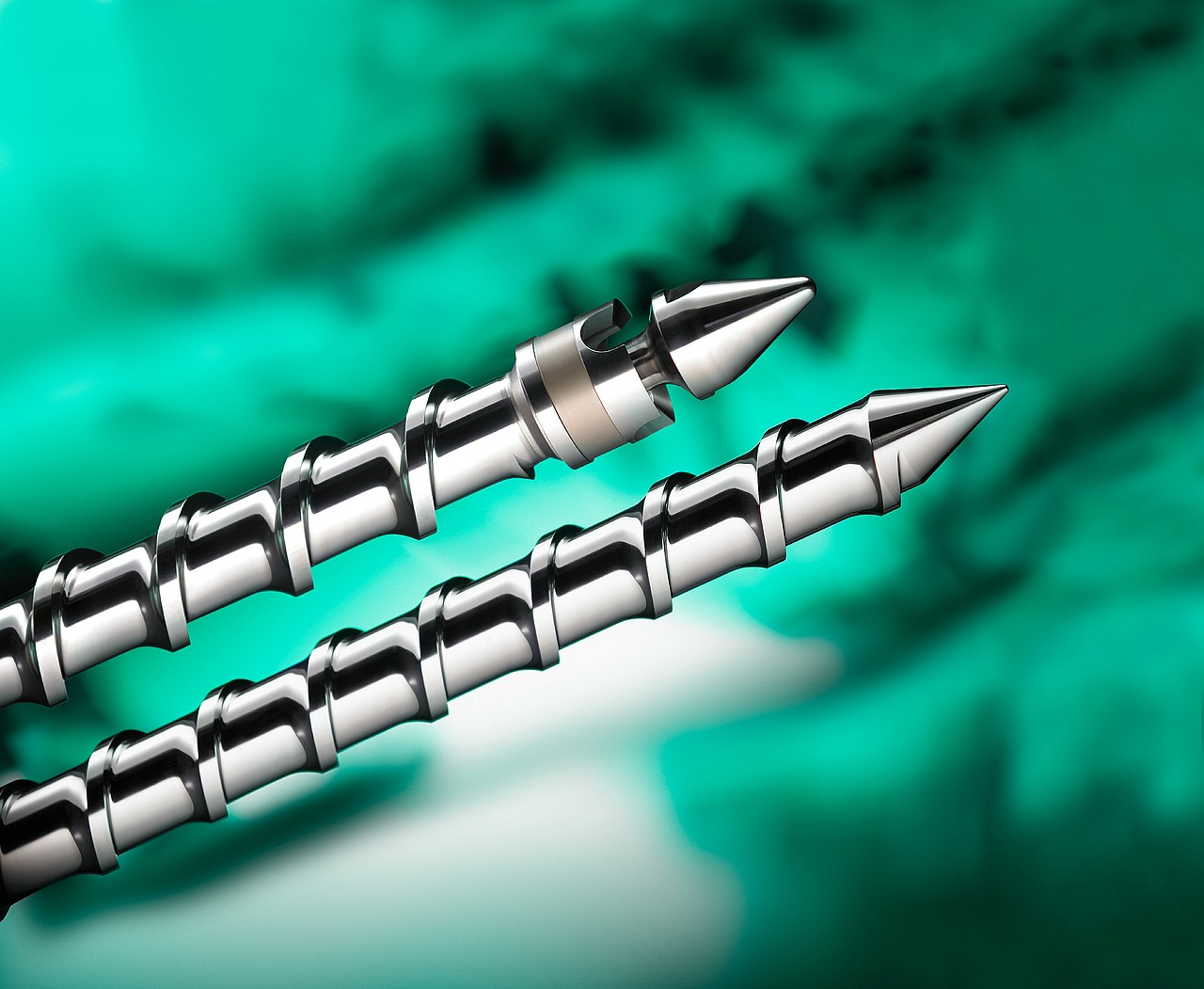

Special cylinder modules

Special cylinder modules

Highly wear-resistant in robust bimetal, adapted injection units for granulated thermosets and moist polyester (BMC) for high production quality.

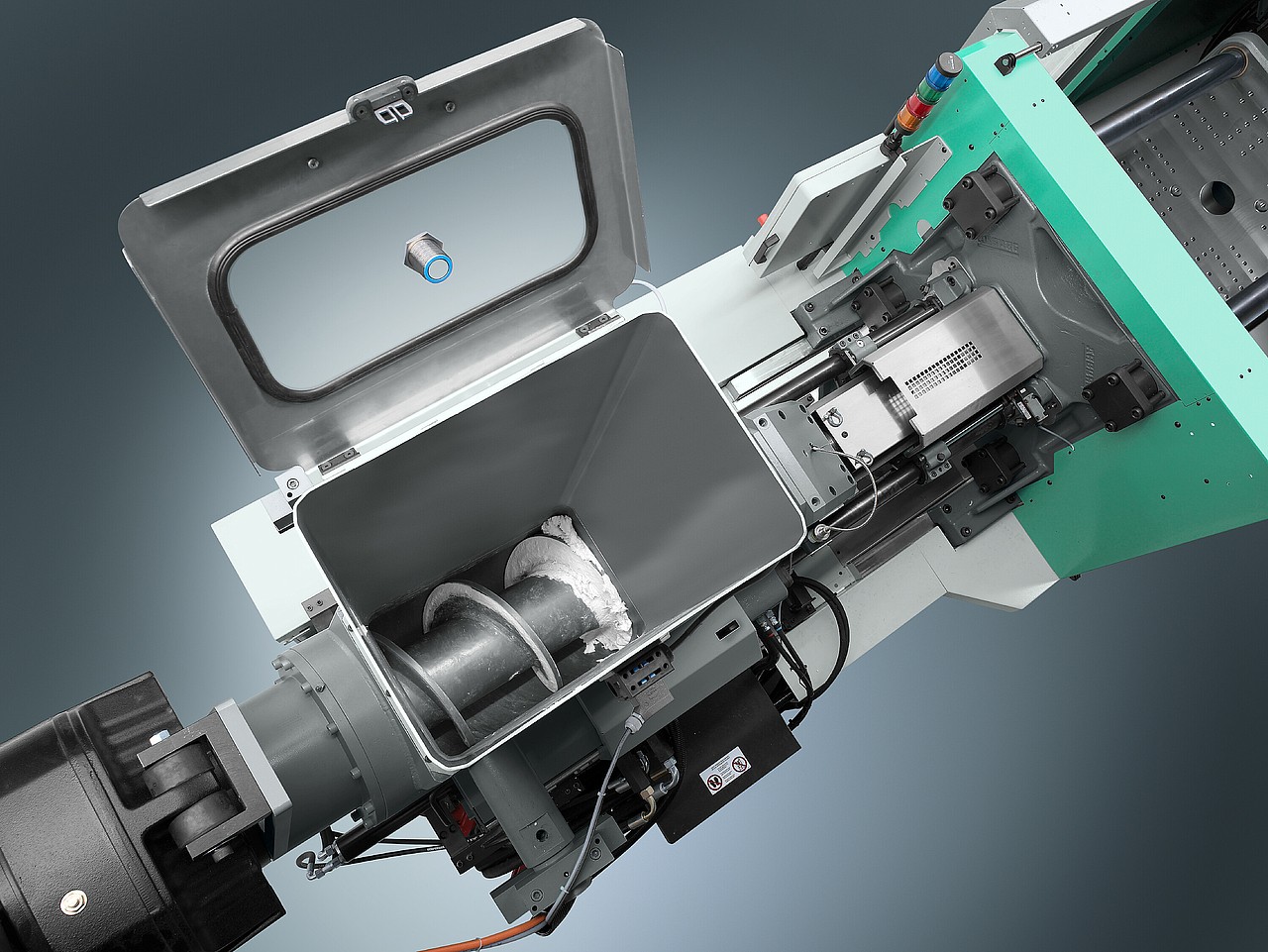

Screw-type INJESTER

Screw-type INJESTER

With servo-electric conveyor screw, large refill container that can be filled during production, high degree of autonomy.

Sample components

Insulating rail

To produce heat-resistant thermoset insulating rails for irons, fibrous BMC is optimally pre-compacted with an INJESTER tamping device.

Car piston

A piston made of granulated thermoset, cost-effectively produced on a hydraulic ALLROUNDER injection moulding machine, can replace metal in car couplings.

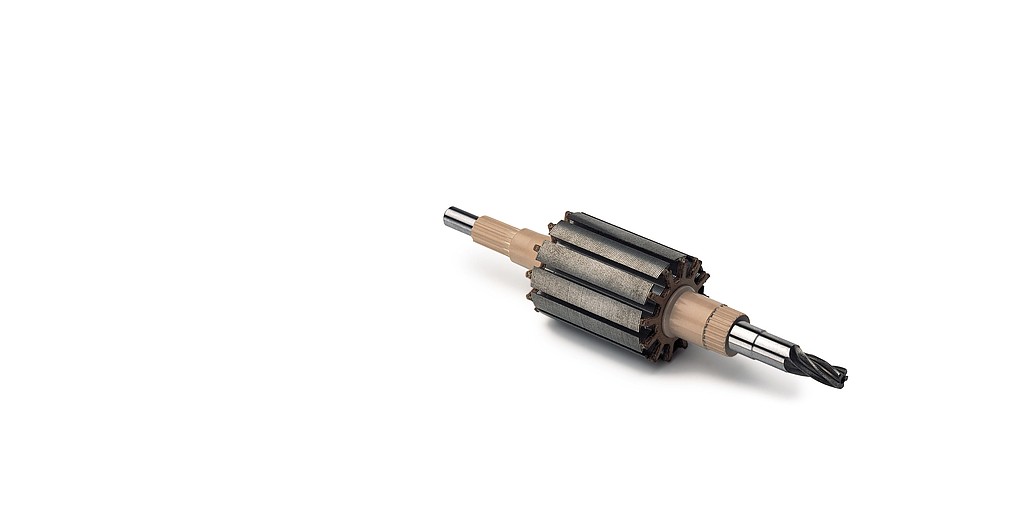

Armature shaft

In armature shafts for electric motors, thermoset ensures a secure connection between the shaft and the stamping package.

Automated production cells from a single source

Want to increase added value, optimise the injection moulding process, automate further, and integrate innovatively? Then we are your partner as a primary contractor. As we are for many leading companies worldwide.

This might also be of interest

Whether in injection moulding or additive manufacturing: with our machines, you can process all commercially available plastic granules and original materials.

Whether in injection moulding or additive manufacturing: with our machines, you can process all commercially available plastic granules and original materials.

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.