Benefits at a glance

Deformable

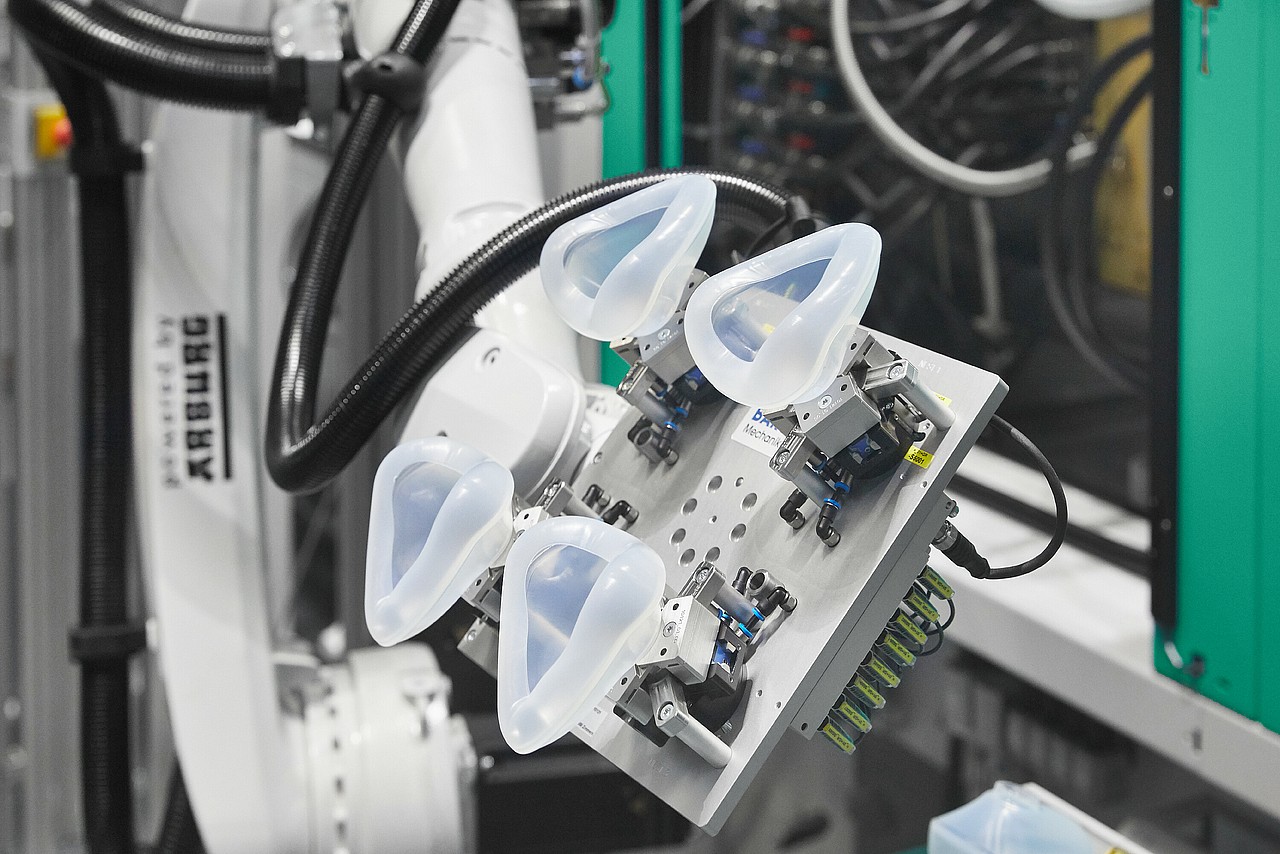

TPE and LSR are flexibly deformable. TPEs behave in a similar way to thermoplastics when heat is applied. Silicones have an even wider application range.

Resistant

Resistant to abrasion, UV and ageing, heat-resistant, electrically insulating, sterilisable, resistant to chemicals. Silicone is the answer.

Temperable

If required, soft materials can be tempered to relieve stresses and further improve mechanical properties.

Universal

The properties of TPEs and silicones make them suitable for universal use – from medical technology to automotive and household applications.

Sample components

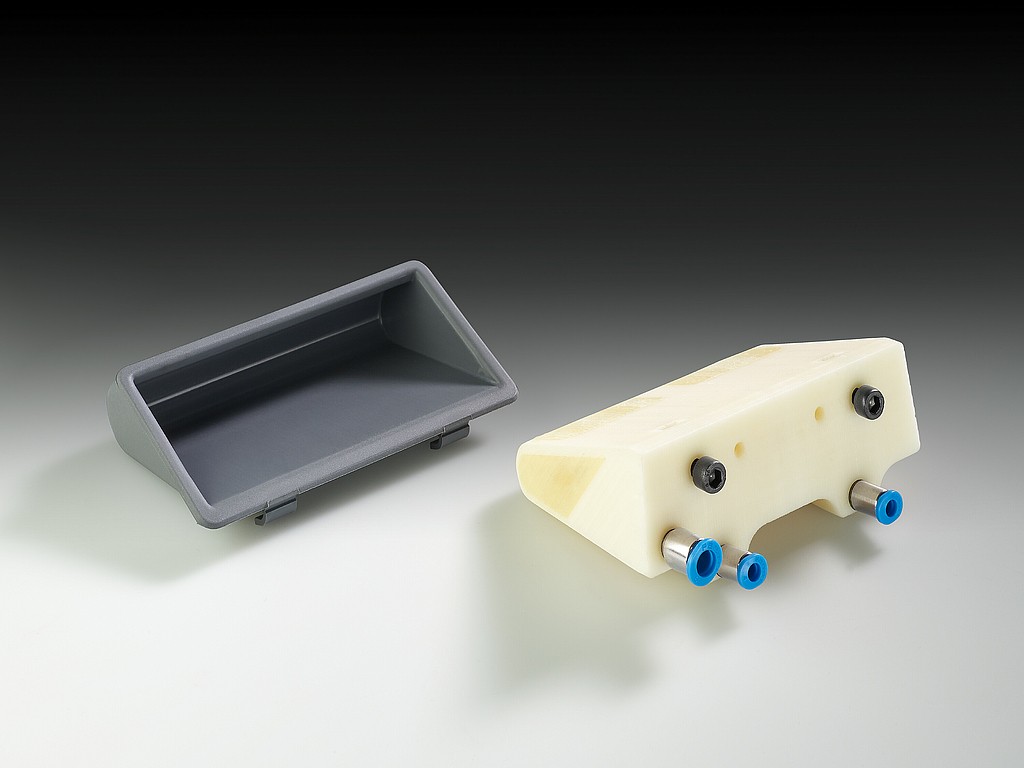

2-component push-button

Twice as soft: the 2-component push-button combines the different properties of two silicones with different Shore hardnesses – no problem on your ALLROUNDERs.

This might also be of interest

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration from our selection of components.

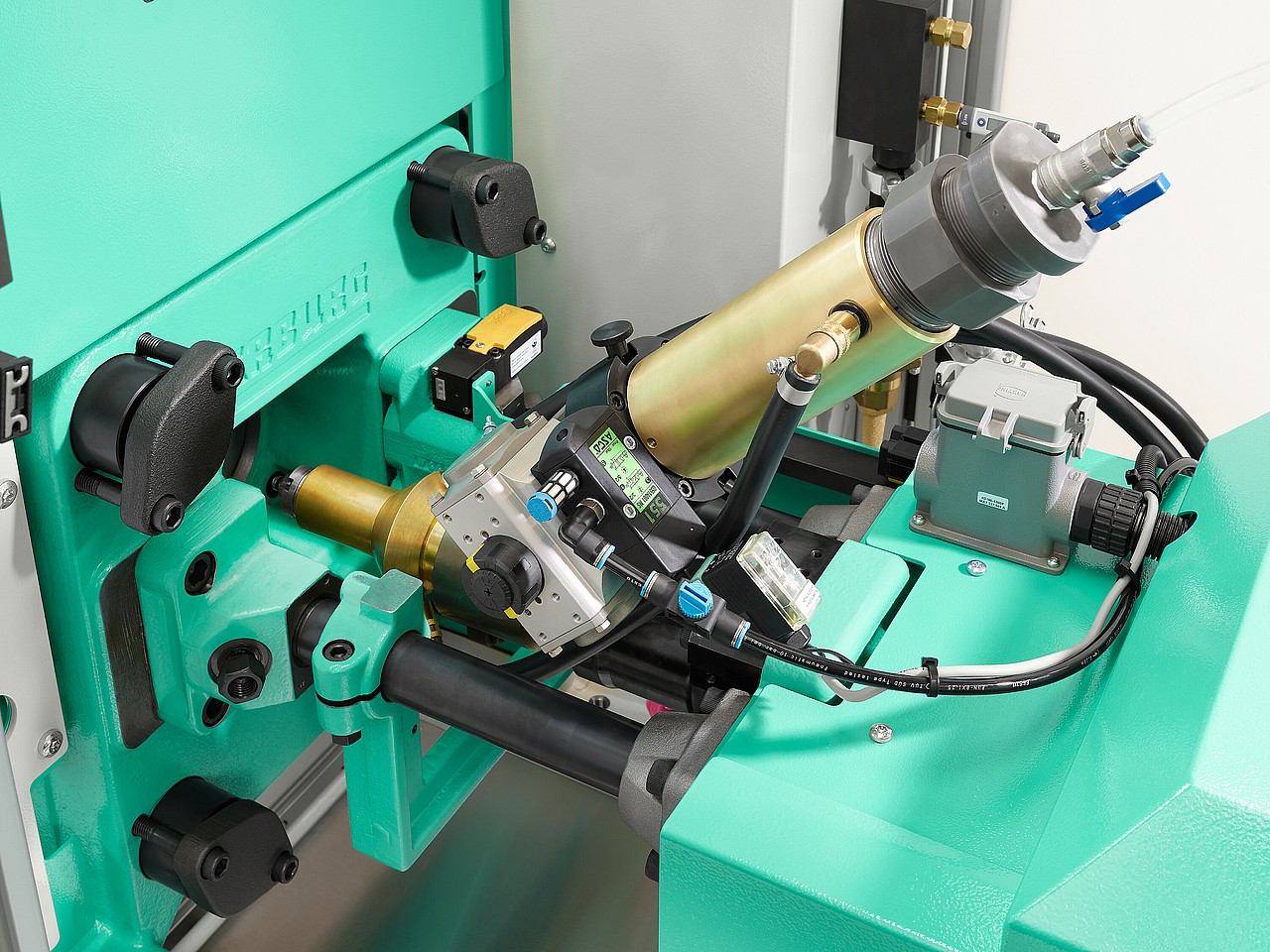

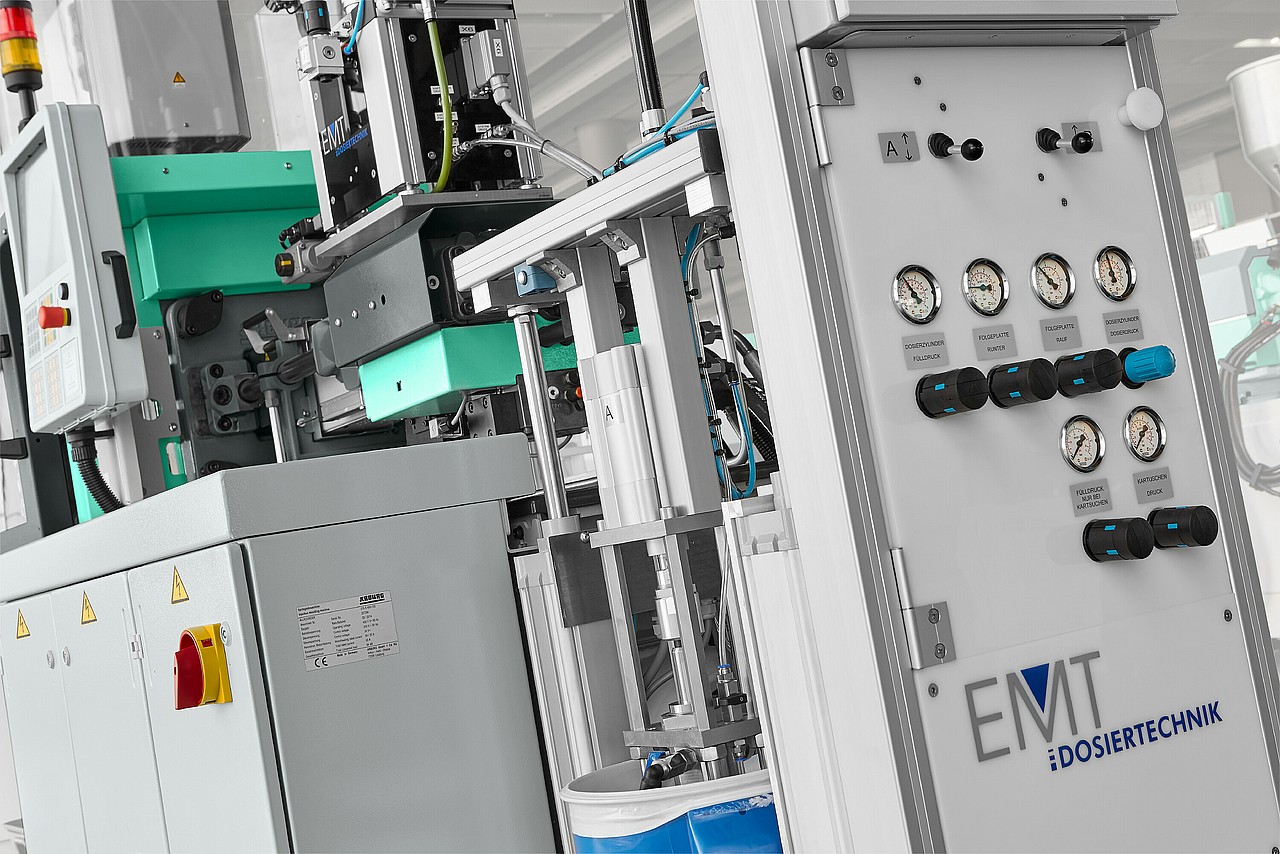

LSR liquid silicones, HTV solid silicones? From liquid or solid to highly elastic. We have the perfect system solutions for you – because we have accompanied this technology for decades.

With 3D printing, you can use the freeformer to process the same original materials and standard granulates as with injection moulding – for example, medically certified TPE.