Ingenious

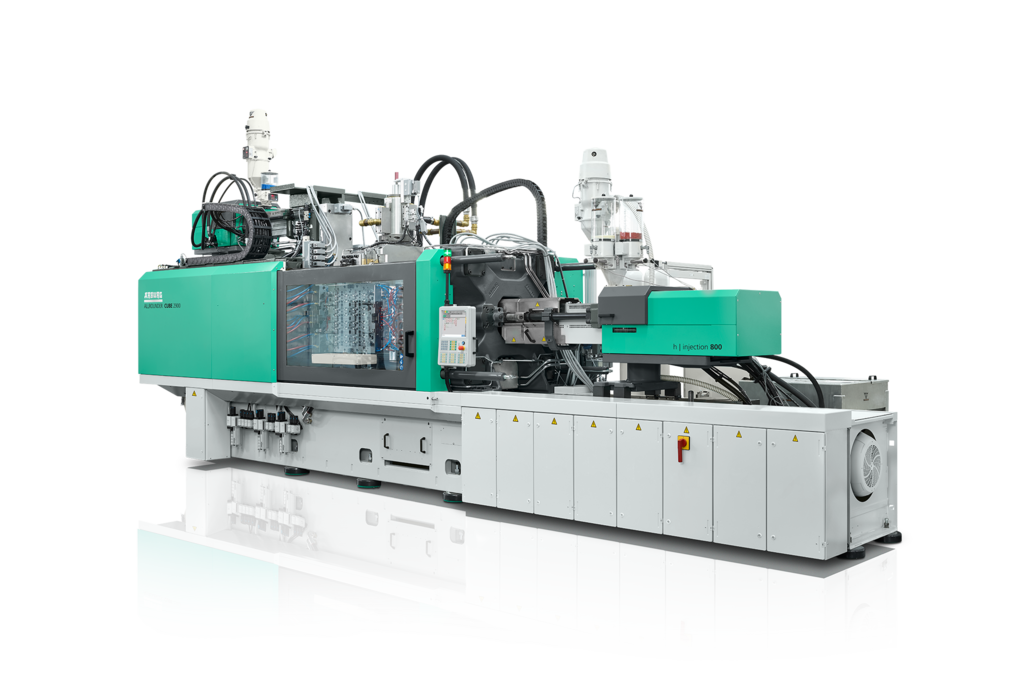

Twice the number of cavities are available with the same mould mounting surface. And all four sides of the cube can be used simultaneously for production steps.

Space-saving

Because two to four separate injection moulding machines simply become one ALLROUNDER CUBE. This reduces your installation area while significantly speeding up your assembly process.

Extra fast

Production, cooling and removal in parallel: During injection, cooling and removal of the finished parts take place simultaneously on the passive mould sides.

Advantages of the ALLROUNDER CUBE

Reduced cycle time

Reduced cycle time

Twice the number of cavities with the same mould mounting surface, saving up to 40 per cent cycle time – that's the big advantage of cube-mould technology. For extremely high output at reduced unit costs

Electric clamping unit

Electric clamping unit

Servo-electric toggles, for fast cycles with reduced energy requirement. Ideal basis for efficient high-volume production.

Travelling injection unit

Travelling injection unit

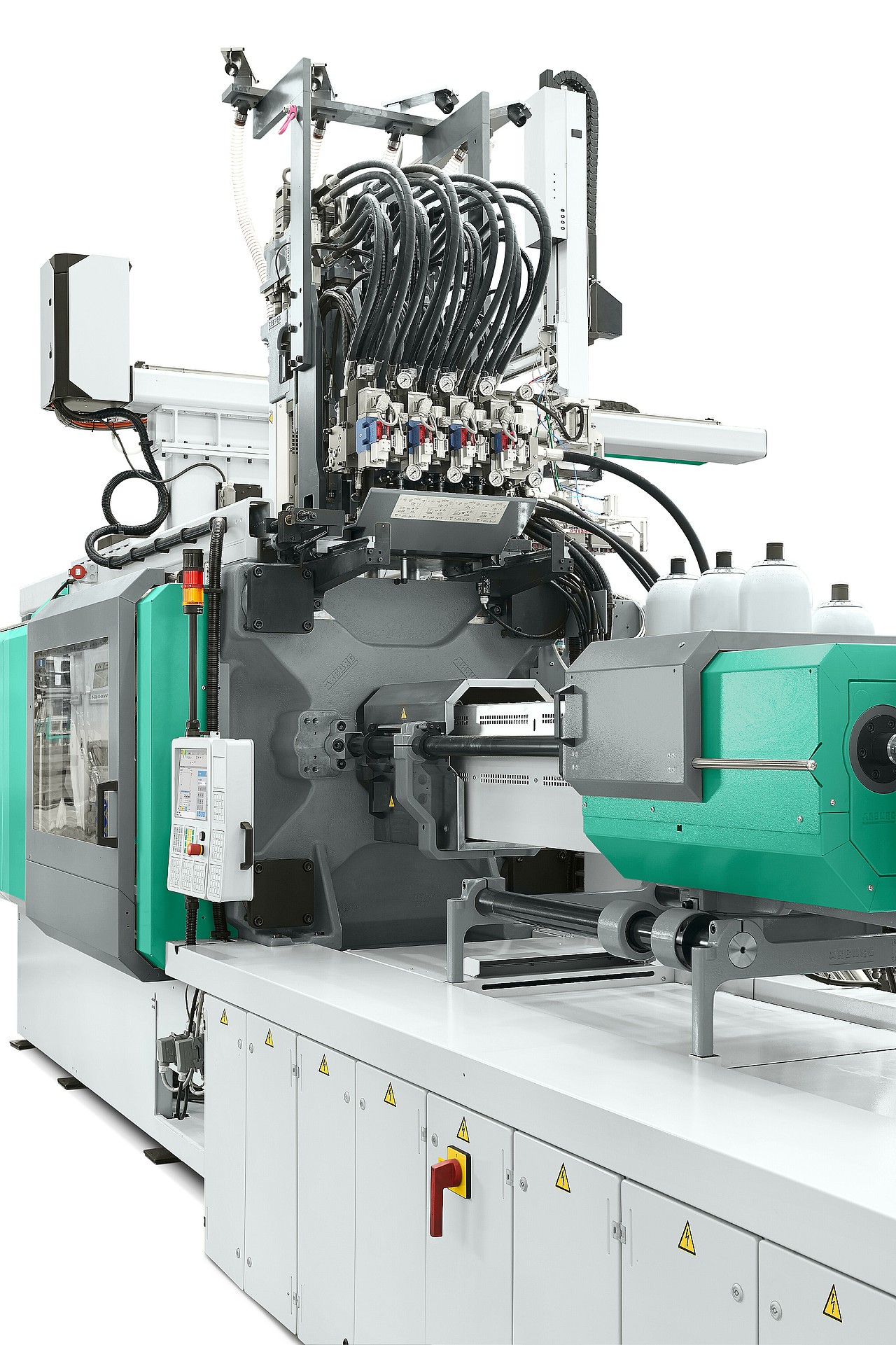

Typical for ALLROUNDER CUBE: second injection unit travelling above the mould mounting platen. Generous mould installation space.

Free sequence programming

Free sequence programming

Cube mould fully integrated into the machine control system, with its own symbols, free sequence programming, individual process sequences.

Series

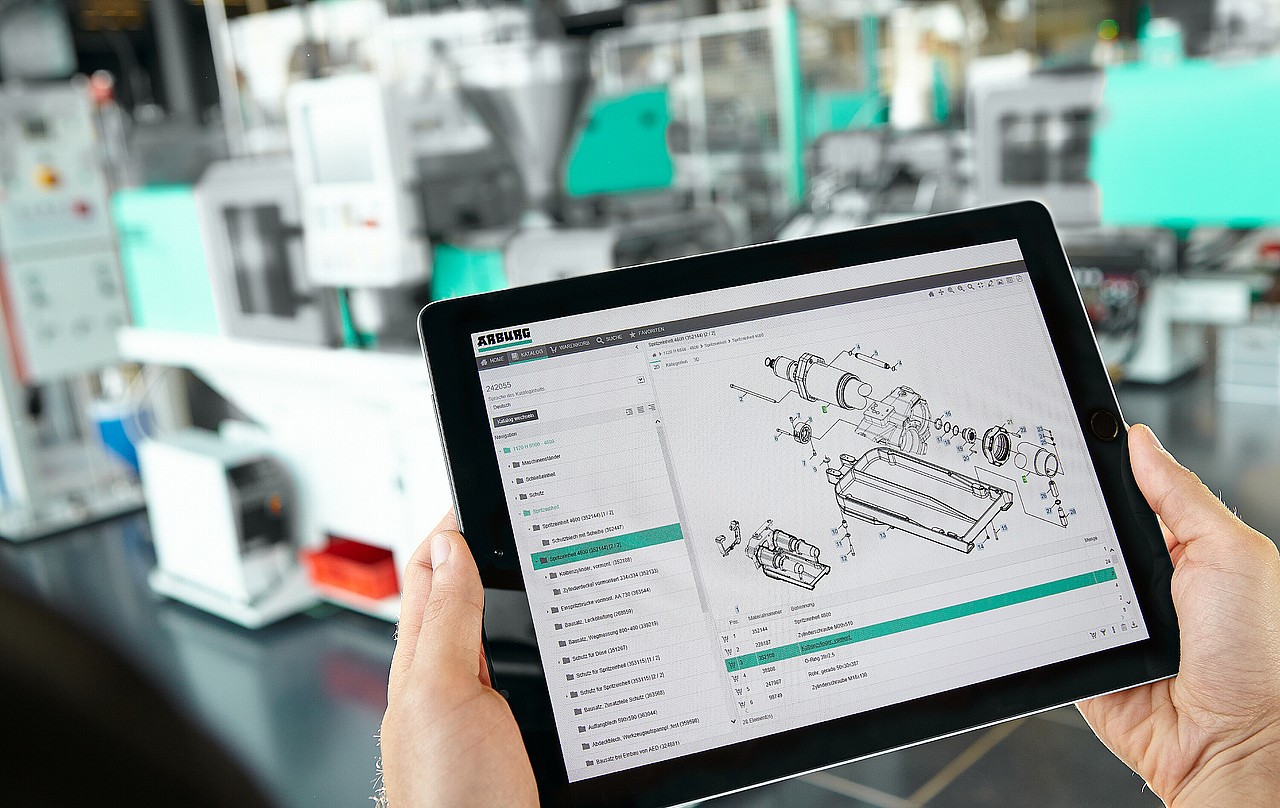

Order spare parts in the customer portal

Are you looking for genuine spare parts from ARBURG? Then order easily and interactively in our arburgXworld shop.

This might also be of interest

Increase added value, optimise the injection moulding process, automate further, integrate with innovation? Then we are your partner as a primary contractor. As we already are for many leading companies worldwide.

Take advantage of synergies for your injection moulding operation with injection moulding machines and robotic systems from a single source. Customise your automation. With technology components that are precisely tailored to your tasks.

Do you want to make optimum use of resources and reduce unit costs? Then ARBURG is the perfect choice for you! Our solutions enable you to achieve maximum productivity with minimum operating costs, resulting in high cost-effectiveness.