Efficient

Give your production a complete overhaul! Take advantage of savings potential across the board! Increase efficiency and utilisation – for example, through reduced cycle times, energy requirements, material usage, standstill times and scrap.

Exhaustive

We take all influencing factors into account. With the aim of exploiting precisely those potentials that pay off in your company and lead to resource-saving, sustainable operations.

Holistic

If you want to create reusable material cycles, you should trust a partner who also approaches things holistically – with high production efficiency and a low carbon footprint in mind.

“To fully utilise production capacities and to be able to operate economically, it is important to maximise the degree of utilisation of each individual machine. This should be made a key issue in every injection moulding facility.”

Andreas Reich, Divisional Manager Applications & Industries

Production efficiency examples

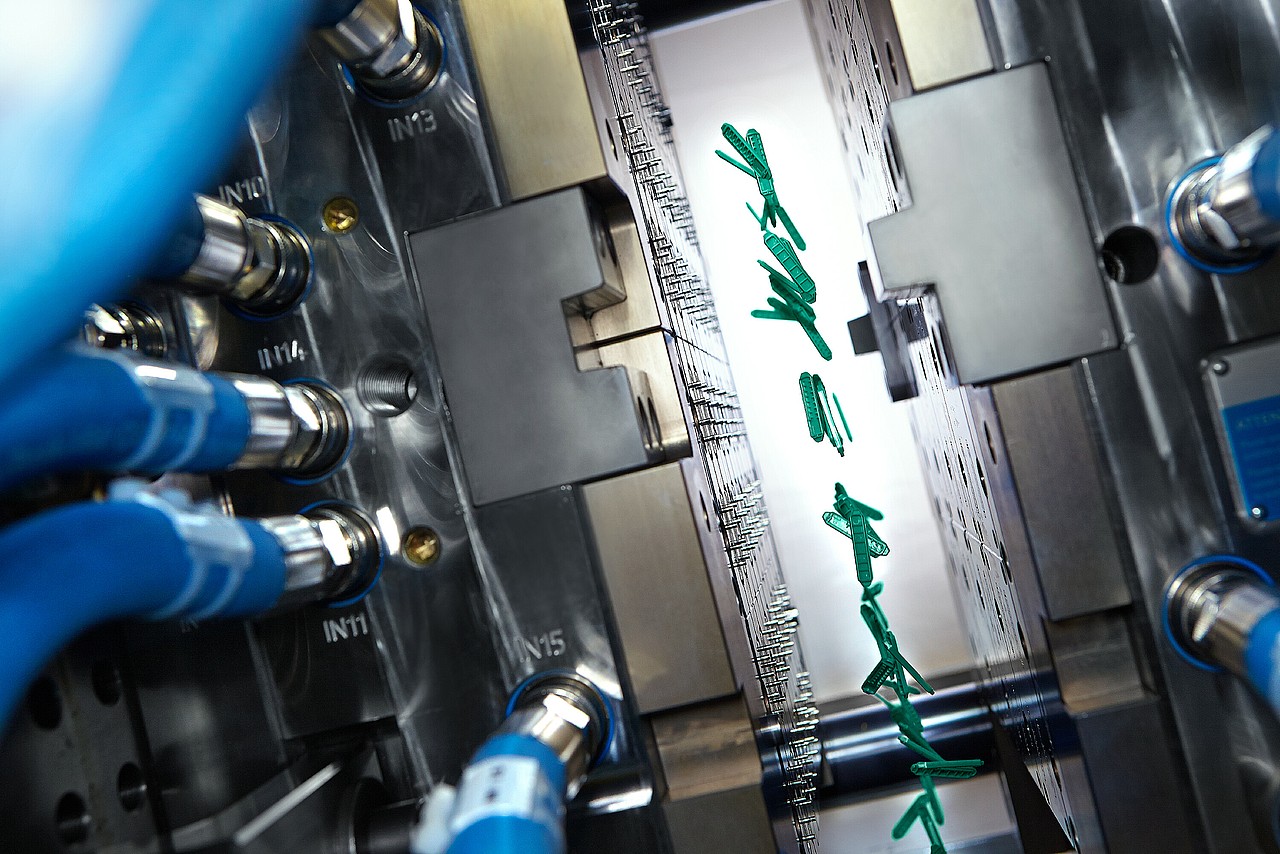

High-end injection moulding technology

64 flat drippers for drip irrigation in just 1.68 s! This is possible when the high-performance electric ALLROUNDER and mould technology are designed for fast cycles. Maximum precision for over 137,000 parts per hour.

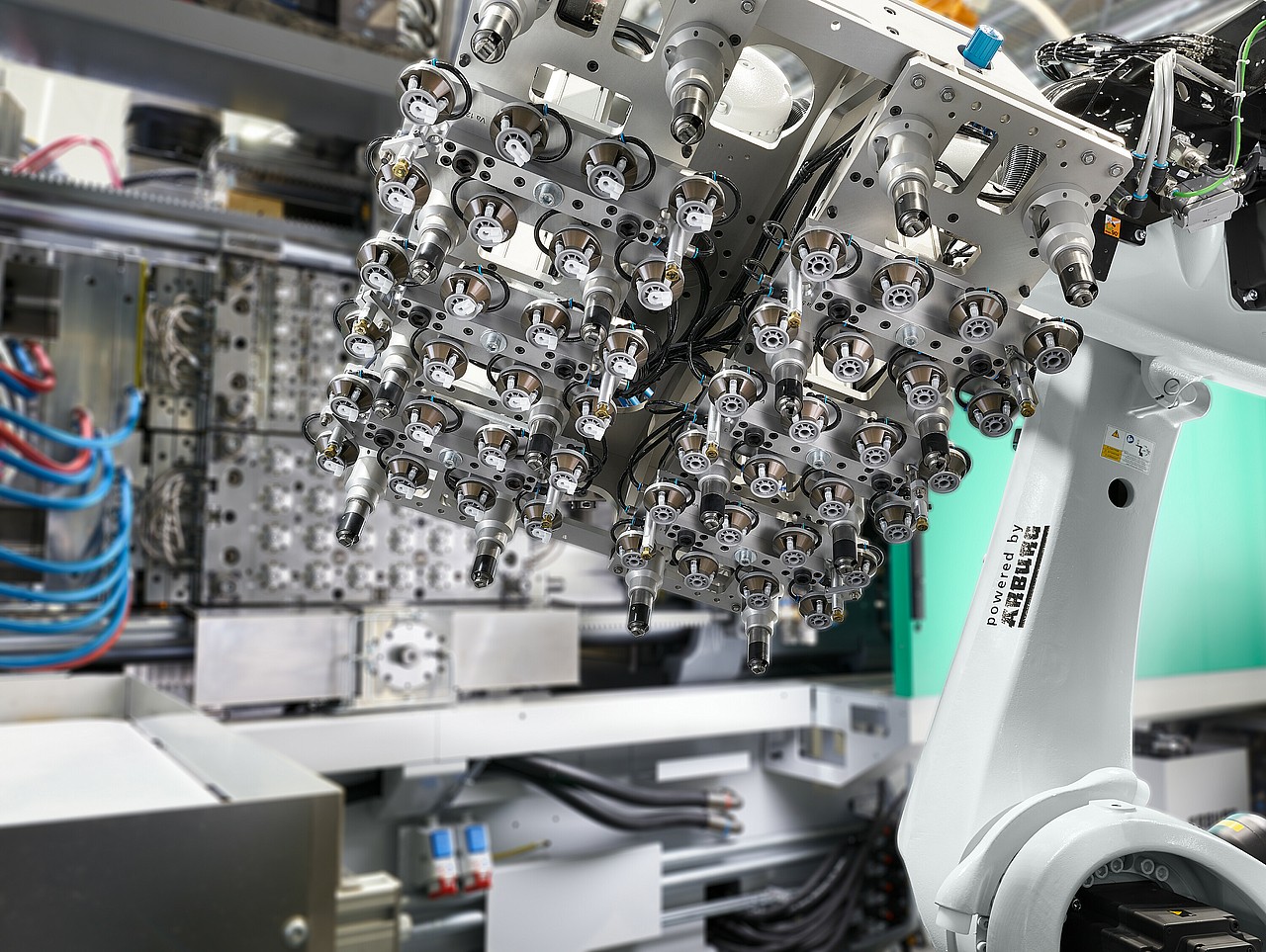

Cube-mould technology

Smaller machine, more output: cube-mould technology saves around 40% cycle time when producing lower basket rollers for dishwashers. The reverse cube system from Foboha and the ALLROUNDER CUBE from ARBURG are designed for maximum efficiency.

Process integration

Ready-to-use step stools are produced on an innovative turnkey system. A linear robotic system removes eight individual parts from the mould. Pre-assembly takes place on a rotary indexing table, and a six-axis robot handles the final assembly.

This might also be of interest

Want to guide your company into digitalisation from a practical perspective? Then you can expect unique digital value-added services with our arburgXworld customer portal.

Want to increase added value, optimise the injection moulding process, automate further and integrate innovatively? Then we are your partner as a primary contractor.

Our modular production management tool – your Manufacturing Execution System (MES). With ALS you can plan and control your entire production system.